You have choices, make the right choice

Multisensor Metrology Systems: The Latest Advancements

The technology available to today’s modern manufacturers – allowing them to create complex parts quickly – is better than ever. Advancements in core production and fabrication equipment are seemingly endless.

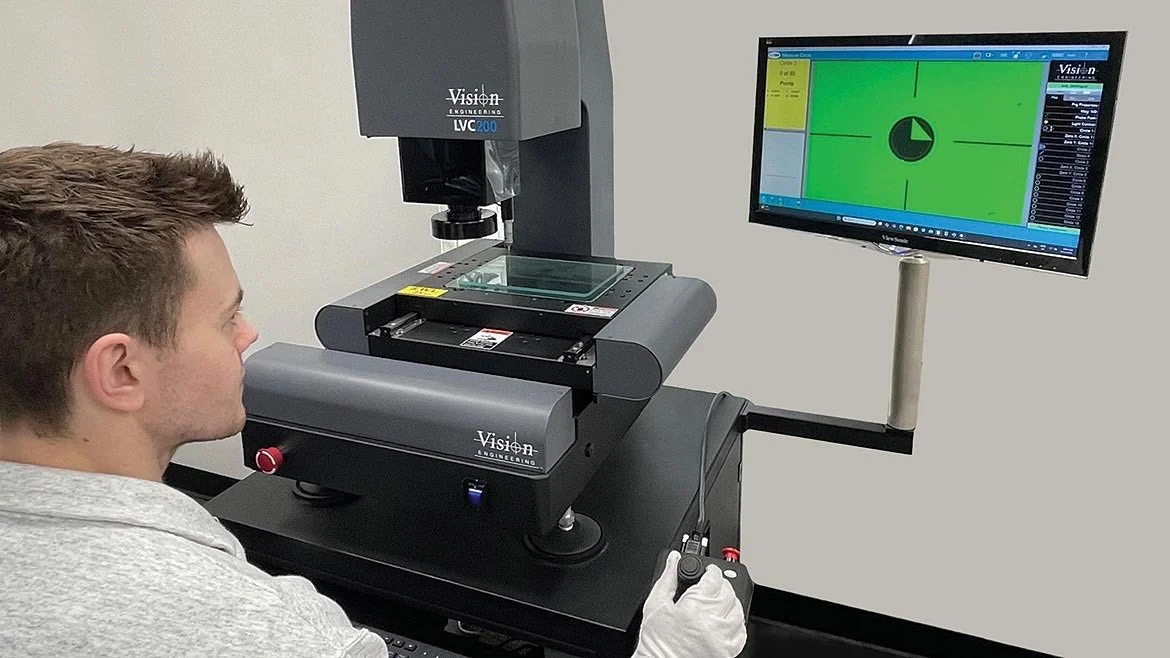

Vision Engineering ProteQ VISO

Vision Engineering announced the launch of ProteQ VISO, a 3D digital stereo microscope featuring a fully integrated autostereo display. The system delivers true 3D visualization directly on a flat screen—no eyepieces required.

Mitutoyo QM-Fit Measurement System

Mitutoyo America Corporation introduces the QM-Fit Smart Vision System. The QM-Fit represents a step forward in optical metrology. The system features a wide field of view that can intelligently recognize part geometry, allowing measurements to be initiated automatically by extracting shapes displayed on the 15.6-inch intuitive color touchscreen.

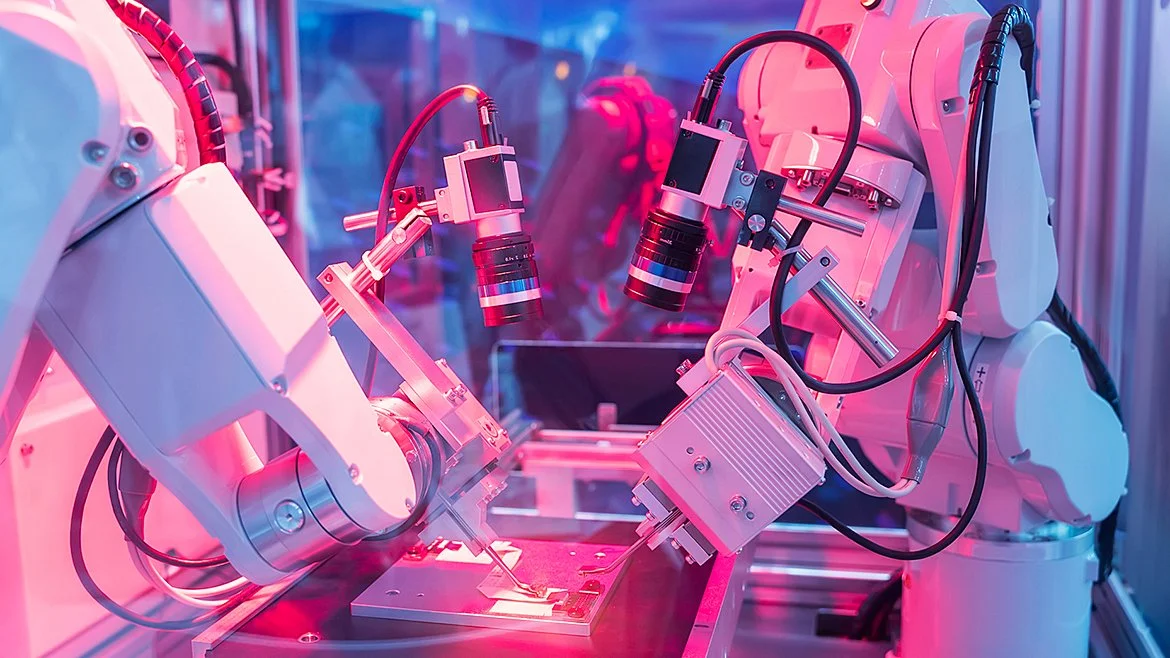

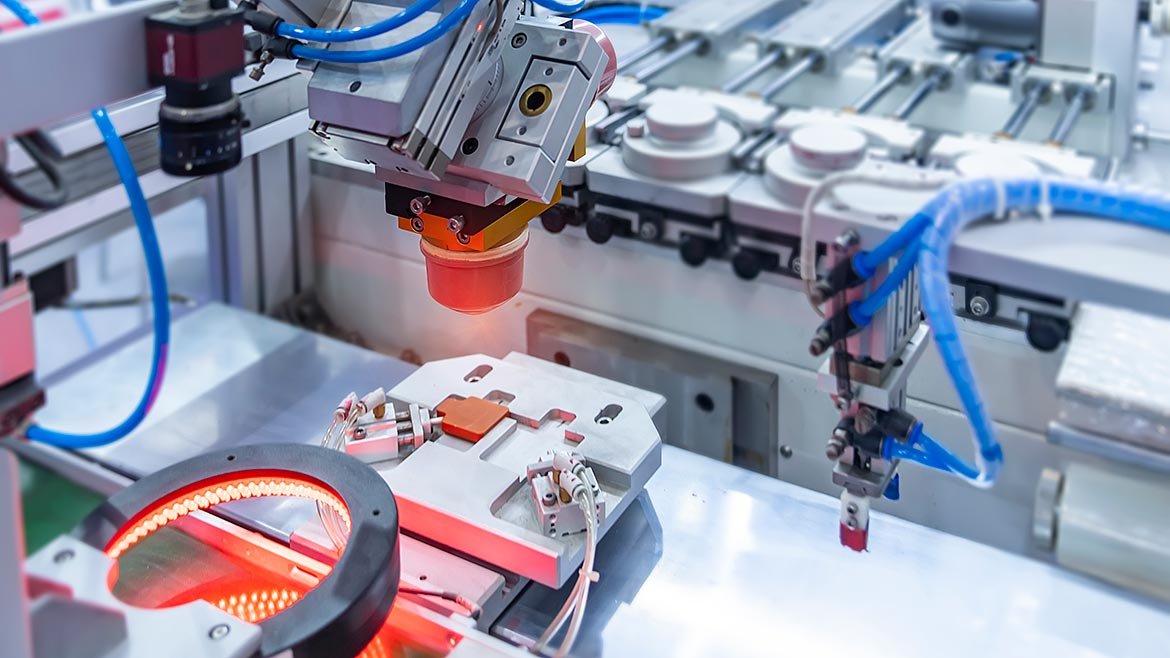

Navigating the Challenges of In-line AI Vision Systems

manufacturers are constantly seeking ways to improve production and product quality. This may involve increasing throughput and scrapping less material, or reducing machine downtime caused by the absence of an inline inspector. Often, their first step is investing in an automated inline machine vision system.

How Advanced LED Control Techniques Are Solving Machine Vision’s Toughest Challenges

Over the past decade, machine vision technology has had to evolve constantly to keep pace with new and fast-emerging manufacturing applications.

Machine Vision Gets Smarter

Machine vision systems are experiencing a significant transformation. Advances in artificial intelligence (AI), deep learning, and 3D imaging are improving inspection capabilities and making these systems more accessible. What once required extensive programming and vision expertise can now be accomplished through AI-powered systems.

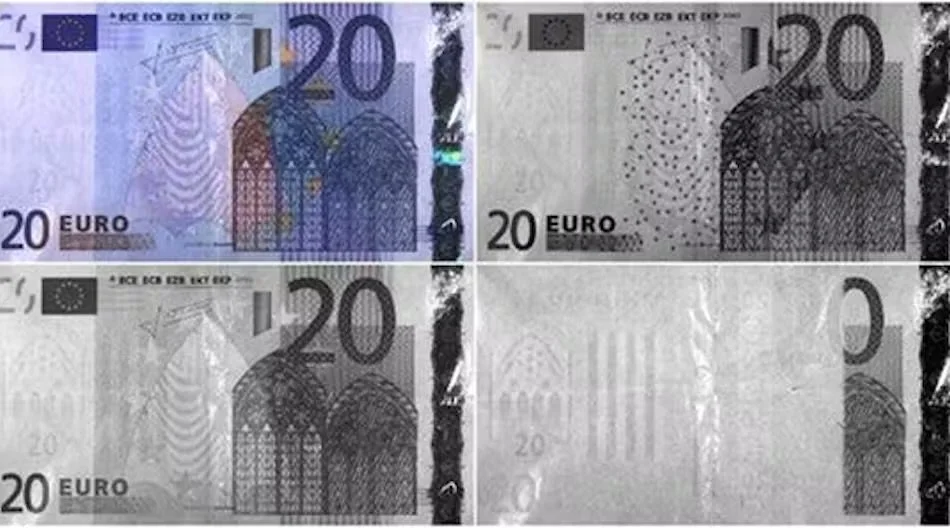

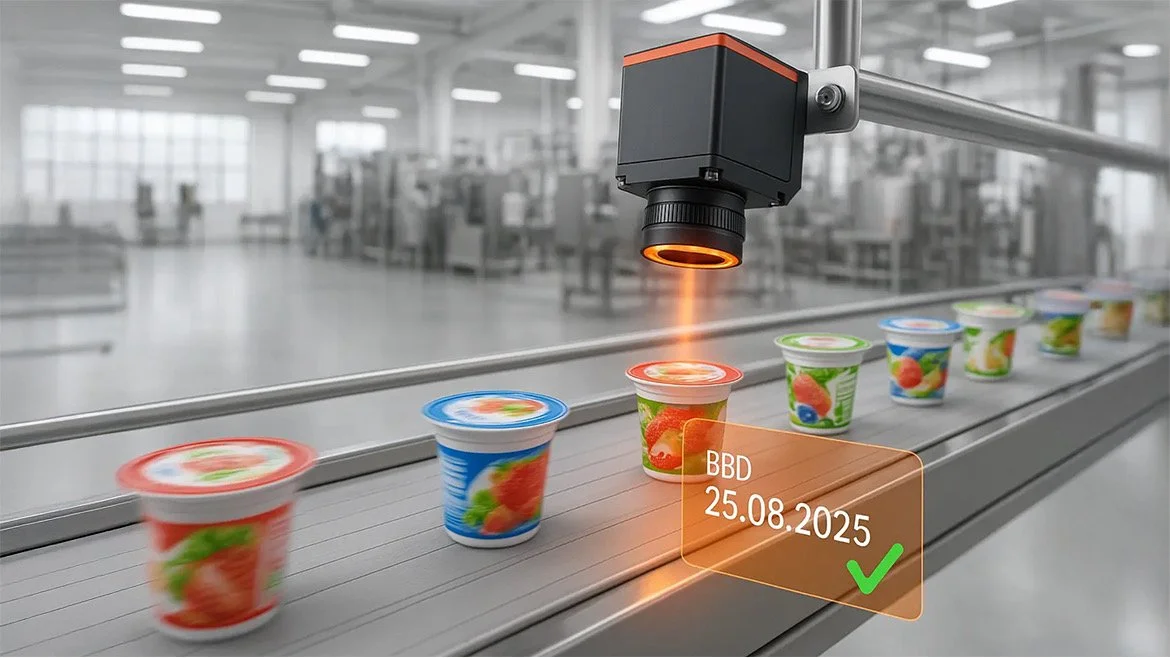

Five Ways Advanced Imaging is Improving Quality

Manufacturers today face growing pressure to deliver safe, high-quality products at faster speeds and higher volumes. Manual inspection just can’t keep up - with its limits in speed, accuracy, and consistency. That’s why advanced imaging technologies are becoming essential on the modern production line.

Precision in Optical Metrology: Telecentric vs. Endocentric Imaging

In industrial quality control and measurement applications, optical metrology plays a critical role in ensuring precision and repeatability. Accurate dimensional measurement of parts, components, and assemblies is essential in industries such as automotive, electronics, and medical devices, yet machine vision systems face challenges due to physical limitations

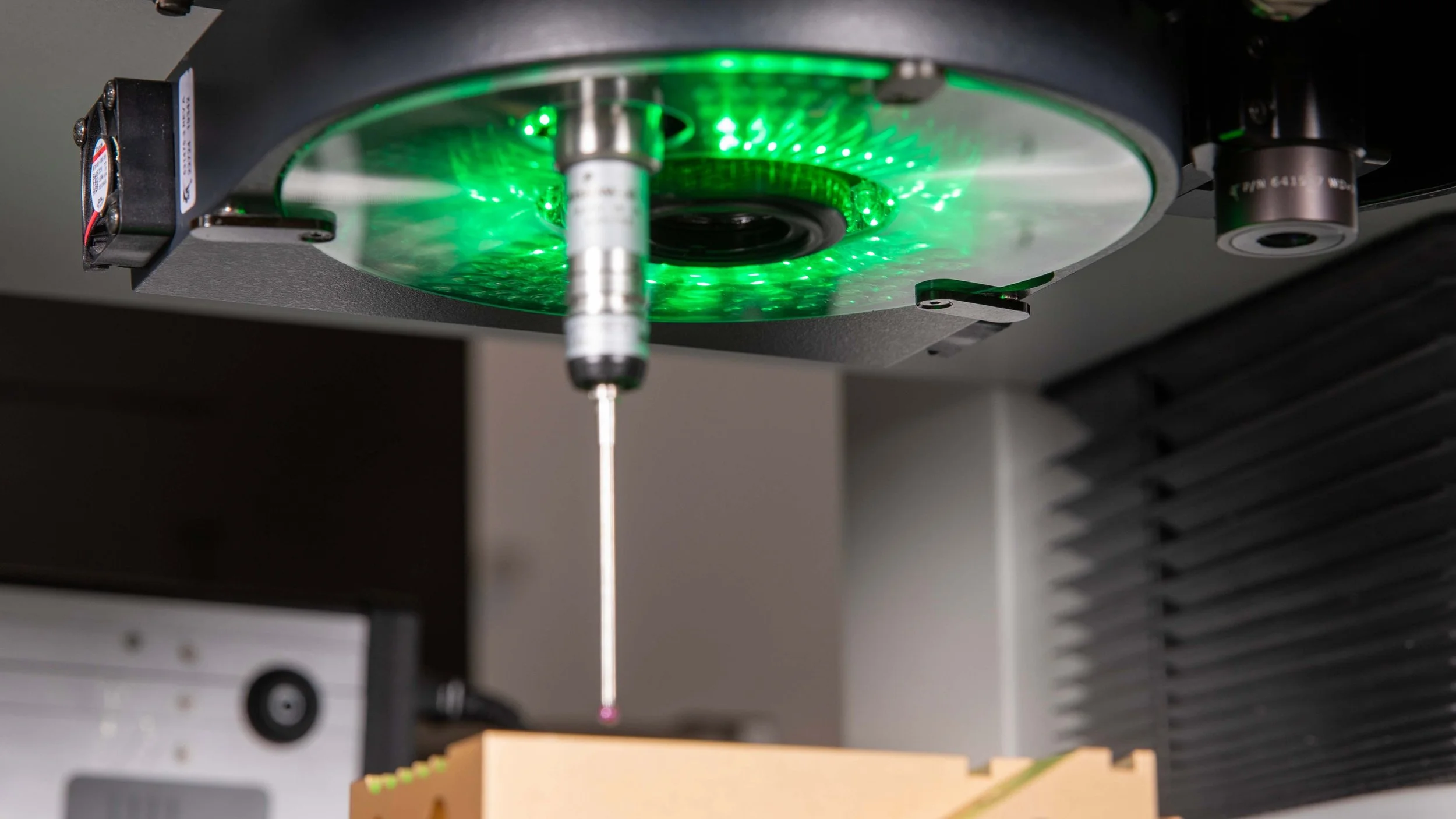

Measure more individually: Your customized 3D measuring station

Mahr has repositioned its optical 3D measurement technology: Measurement technicians, quality assurance specialists and researchers can now put together the right system for their own measurement tasks from a wide range of possible combinations. The result is an individual, tailor-made measuring station.

A Perfect Match: The Critical Role of Matching in Machine Vision Technologies

The search for a perfect match isn’t unique to dating platforms. It also applies to machine vision, where users are also looking for perfect “counterparts.” Matching technologies in machine vision software ensure that objects in the image are precisely located.

Multisensor Metrology Explained

What is multisensor metrology technology? Multisensor metrology combines numerous methods and capabilities to analyze and quantify part measurements using repeatable and reproducible techniques. Providing access to digital camera measurements, touch probing and digital overlays all in one system are typical examples of multisensor metrology.

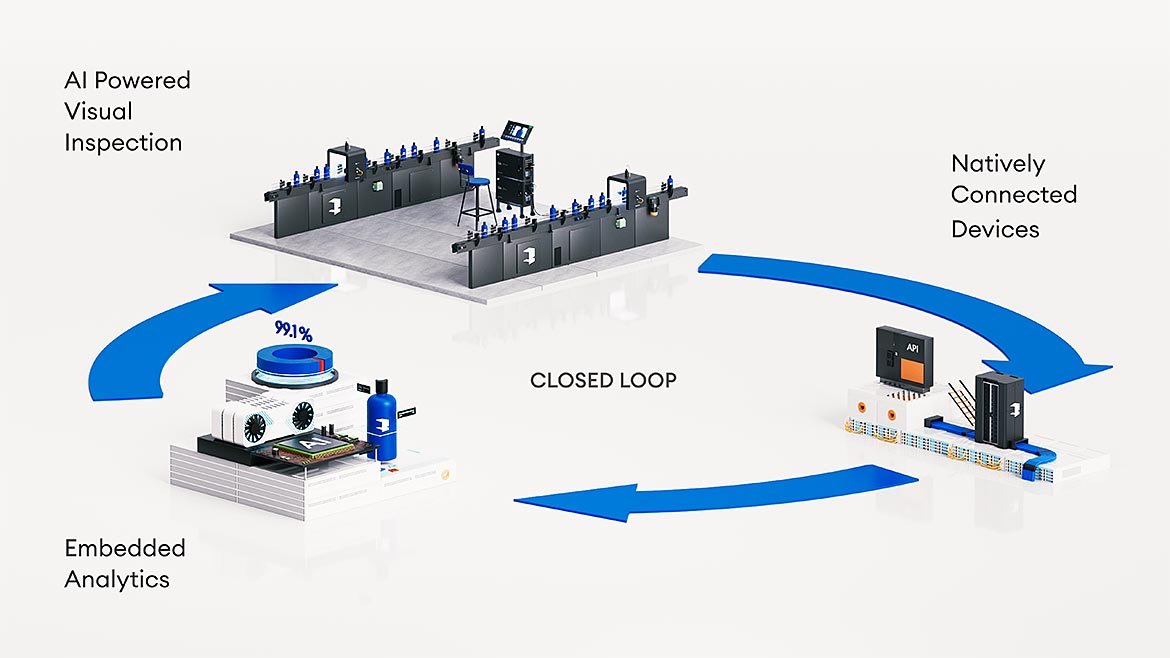

The Next Frontier of Automation: Quality Assurance in an AI-Driven Era

The convergence of automation and quality is redefining how manufacturers detect defects, maintain standards, and continuously improve processes.

Difference Between Calibration and Verification

When it comes to in-the-field calibration of video measuring systems and other high-end measuring equipment, companies I talk to often do not realize or understand the difference between verification and calibration.

How Closed Loop Quality and AI-Driven Machine Vision are Transforming Manufacturing

Unlike traditional quality control methods, closed loop systems enable real-time adjustments and proactive problem-solving.

Machine Vision Software Trends

While AI is often touted as cutting-edge, its practical application is helping manufacturers reduce time spent on repetitive tasks and automate decision-making.

Zeiss Industrial Quality Solutions transitions to direct sales in Canada

Zeiss Industrial Quality Solutions, a company specializing in metrology and inspection technologies and software, is transitioning to direct sales in the Canadian market for Zeiss coordinate measuring machines (CMMs); vision measuring machines (VMMs); CT/X-Ray solutions; industrial light microscopes; and surface, form and geometry (SF&G) products, effective Jan. 1, 2025.

The Expanding Role for Machine Vision in Smart Factories

As companies strive to improve productivity, efficiency, and quality, more are turning to concepts like smart manufacturing, smart factories, and Industry 4.0.

The Next Wave of Machine Vision Interfaces

One of the biggest game changers for machine vision has been the introduction and standardization of interfaces. In the earlier years of this century GigE Vision and Camera Link, followed by CoaXPress (CXP) and USB3 Vision, all made it easier to design, deploy, and integrate machine vision cameras, sensors, and processing.

ZEISS O-INSPECT duo – Microscope and Measuring Machine in One.

ZEISS is an internationally leading technology enterprise operating in the fields of optics and optoelectronics.

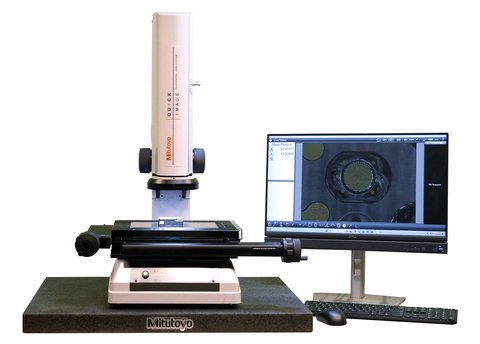

Mitutoyo America Corporation Releases New Metlogix M3 with the Mitutoyo Quick Image Vision System

Mitutoyo America Corporation, a leader in precision measuring instruments, is excited to announce the integration of the powerful Metlogix M3 software into the Mitutoyo Quick Image (QI) 2D Vision Measuring System. This latest enhancement promises to elevate the precision and efficiency of non-contact measurements, further solidifying Mitutoyo’s commitment to providing innovative technology solutions to meet modern quality control needs.