Machine Vision Gets Smarter

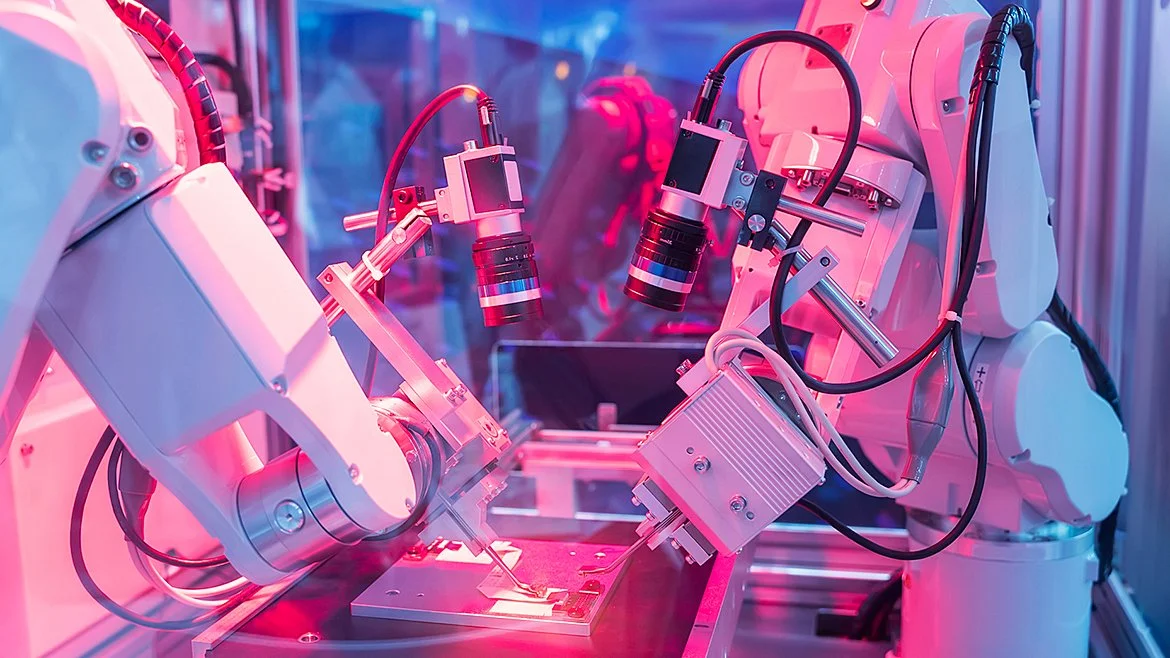

Machine vision systems are experiencing a significant transformation. Advances in artificial intelligence (AI), deep learning, and 3D imaging are improving inspection capabilities and making these systems more accessible. What once required extensive programming and vision expertise can now be accomplished through AI-powered systems.

“There has never been a time when this was more real,” says James Witherspoon, director of systems engineering at Zebra Technologies. “AI, deep learning, and 3D imaging are allowing companies to solve challenging quality inspections that could not be done before, and allowing them to simplify traditional inspections.”

Beyond the AI Hype

Still, AI is not a universal solution.

“There is still a lot of hype, and the uninitiated might get the impression that AI can do pretty much anything, which is certainly not the case,” says Marc Fimeri, managing director at Adept Turnkey. “However, when an application lends itself to AI and deep learning it is a very useful tool to create applications that would otherwise be impossible or at the very least extremely difficult with conventional algorithmic programming.”

David Dechow, industrial factory solutions architect at Motion Automation Intelligence, notes that machine learning and deep learning are the most relevant for machine vision applications.

“Early on, a common value proposition for deep learning (DL) was that it could do everything that ‘traditional’ machine vision could not, and that it was going to replace all machine vision technology,” Dechow says. “The first claim may be true in some isolated cases, but despite the original hype, ultimately DL technology has limitations and now has been better positioned as a part of the larger machine vision algorithm toolset.”

Deep learning excels in two key areas, Dechow says. First, vendors have developed models for specific inspection tasks, such as scratch detection and optical character recognition, that require little or no training. Second, deep learning simplifies extremely basic inspection applications through ease of use, even though traditional machine vision tools could accomplish the same tasks.

Anomaly Detection Takes Center Stage

One application driving AI adoption is anomaly detection, which Witherspoon describes as “sort of the entry level when getting into AI solutions.” These systems learn what normal parts look like and flag deviations automatically.

“Nowadays, simplified inspections involve training a neural network on the specifications and parameters of the standard parts, to be able to flag and reject any deviations,” Witherspoon says.

This approach addresses a common challenge manufacturers face: they’re getting better at not making defective parts, making it harder to build strong vision systems.

“Manufacturers are getting really good at not making bad parts. So, finding the issues and testing the accuracy of the systems is often a challenge,” Witherspoon says. “If you only have a good part, it is hard to build a robust vision system around it. How do you inspect for something you haven’t seen or made yet?”

Synthetic data generation helps fill this gap, allowing manufacturers to create training data for defects they haven’t yet encountered in production.

3D Imaging Comes of Age

Three-dimensional imaging technology has become a reliable, widely adopted solution. The technology has moved beyond its experimental phase to become standard equipment in many applications.

“Three-dimensional imaging has evolved past its nascent development stage and is now a commonly used and well-established technology,” Fimeri says. “Stereo, projected stereo and laser profiling cameras account for the majority of application we get involved with, but Time of Flight is another camera type that is improving and gaining traction in the market.”

For example: Stereo vision works well for robotics applications, while laser profiling is more appropriate for conveyor-based product inspection. Three-dimensional imaging technology has advanced over time. It is now available in higher resolution, and can perform more consistently across conditions. It’s also become easier to implement.

“Three-dimensional imaging systems have gained more resolution, deliver more and better 3D data, perform better under varying imaging conditions, automatically deliver rectified 2-D color or texture images, and have become easier to implement with more standardized interfaces and software,” Dechow says.

The combination of 3D imaging with AI is particularly powerful. “Three-dimensional inspections allow for depth to be used when looking at quality. It can be combined with deep learning to create new, powerful solutions to help manufacturers solve applications that could not be done in the past,” Witherspoon says.

Industry Applications Drive Growth

Several industries are leading machine vision adoption. Transportation and logistics rank high among growth sectors, as companies work to prevent damaged products from entering the supply chain.

“In transportation and logistics, customers are looking to stop damaged boxes and products from being shipped around by using a mix of 3D imaging, deep learning, machine vision and barcoding solutions,” Witherspoon says. “We are even starting to see Short-Wave-IR Short-Wave Infrared (SWIR) inspections that look for leaking products in boxes entering the transportation and logistics space.”

Fimeri sees growth in intelligent transportation and infrastructure inspection. “Agriculture is also a developing market and mining is potentially going to be much bigger than it is right now,” he says. “We also see a lot of applications growing for airborne drone imaging, predominantly in agriculture.”

Manufacturing applications continue expanding as products become more complex. “In manufacturing, AI and 3D imaging continue to grow, driven by need to ensure electrical connections are secure in various products, from dishwashers to automobiles,” Witherspoon says. “As products become more advanced and incorporate more electronics, the requirement to verify connectors intensifies.”

Dechow notes that machine vision growth often follows broader market trends. “Really, the growth of machine vision for a particular industry or market simply follows the growth of the market itself,” he says.

Implementation Challenges Persist

Despite technological advances, manufacturers still face significant challenges when implementing machine vision systems. Finding qualified partners tops the list of concerns.

“The biggest struggle for manufacturers is finding suitably qualified partners to help guide and develop the most appropriate vision solution,” Fimeri says.

Long-term reliability is another major hurdle. Systems may work initially but face problems as conditions change.

“Technically, the biggest hurdle in implementing vision systems is to ensure they remain reliable over long periods of time,” Fimeri says. “Vision systems are installed successfully and work reliably for a period of time but all too often variations in operating conditions and product cause longer term problems reducing accuracy and reliability.”

Natural products often present a challenge. “Carbon based products such as food often vary from season to season and it can take two to three seasons for a vision system to work reliably with the variability of product,” Fimeri says.

What to Look for in New Systems

Manufacturers today want complete systems that solve specific problems, not individual cameras and software they have to piece together themselves.

“Manufacturers expect solutions, not components that make up solutions anymore,” Witherspoon says. “When they do invest in a solution, they have high expectations. People expect vision systems to be flawless, see issues, and detect them like human operators, 100% of the time.”

While perfect performance may not happen immediately, manufacturers can shorten the learning curve by selecting flexible systems that are easily expandable and scalable, Witherspoon says. “Look for systems that can run on various types of hardware and can be ported over and switched with ease,” he explains.

Poor lighting and optics will doom any vision system, no matter how advanced the software.

“Spend time making sure that the lighting and optics are fully optimized,” Witherspoon says. “If you don’t spend the time and resources to create the best image, you will end up with poor results, junk in/junk out.”

Building a library of inspection images helps improve systems over time and provides data for testing new AI approaches.

“Save the images of your inspection, the good, the bad and the ugly,” Witherspoon says. “The images can be used to test the system, improve the system, and try new solutions that are AI-based.”

Dechow recommends focusing on application needs rather than technology: “Focus only on the needs of the application, not on machine vision technology. How will a process or the manufacturing environment as a whole benefit if actionable data were available from a specific operation?”

Understanding the context of system performance helps set realistic expectations. Fimeri notes that requirements vary depending on the system’s purpose.

“This often depends on the primary reason a vision system is installed,” he says. “It can be to replace manual inspection to reduce operating costs and in these cases the manufacturer will often not have as high an expectation on performance and quality. A vision system typically will not be as accurate as visual inspection by an operator, but a vision system is much more repeatable and predictable.”

Future Technologies on the Horizon

Looking ahead, several emerging technologies promise to further change machine vision capabilities over the next three to five years.

These advanced imaging systems can see beyond visible light to identify materials and detect defects invisible to standard cameras.

“Hyperspectral and multispectral imaging are gaining momentum in the market with developers and integrators looking for better ways to segment images,” Fimeri says. “Minerals, agriculture, defense are the key markets for multi-dimensional spectral imaging.”

Camera manufacturers are now building ruggedized versions designed for factory floors rather than laboratory benches.

“We are seeing hyperspectral transition from scientific research applications to industrial applications and the manufacturers of these products now designing hyperspectral cameras with the features required for industrial inline imaging,” Fimeri says.

Short-wave infrared (SWIR) cameras can see through packaging to detect moisture, contamination, and other problems invisible to regular cameras.

“In the past, this technology has been too expensive for most to deploy and very niche,” Witherspoon says. “As it becomes more cost-effective, the adoption will continue to grow. Applications in food and beverage, pharma, and the super-scaling transportation and logistics industry will allow for new types of inspections and solutions.”

The next wave of AI development focuses on making these powerful tools simple enough for non-experts to use.

“AI, without a doubt, will continue to lead the way in the next three to five years and beyond,” Witherspoon says. “New algorithms and models to make the impossible happen. New ways of programming vision systems to make it easier for the masses.”

However, Dechow cautions against expecting revolutionary changes. “There are no unicorns in today’s machine vision marketplace,” he says. “Historically, there haven’t been many emerging machine vision technologies that have had huge impact. However, the change is always incremental.”

Machine vision technology is advancing, driven primarily by AI integration and 3D imaging improvements. But to get results, manufacturers need to understand what they’re trying to solve, choose the right partners, and design systems correctly from day one.