Evolving Roughness Standards: Understanding and Implementing ISO 21920

With ISO 21920 bringing a myriad of changes for metrology professionals, it is critical that all elements of the standard are understood for accurate measurements.

By Polytec Surface Metrology Team

In the world of precision manufacturing and quality assurance, surface texture plays a vital role in performance, durability, and functionality. In the past, profile-based roughness evaluation was dictated by a fragmented set of standards. With the introduction of ISO 21920, these standards have all been combined into one. This streamlined new standard brings together decades of accumulated experience into a new format, aiming to improve communication, consistency, and interpretation across the surface texture measurement space.

With ISO 21920 bringing a myriad of changes for quality inspectors, design engineers, and metrology professionals, it is critical that all elements of the standard are understood for accurate measurements. Each section below will highlight one of the main sections of ISO 21920 and its practical application for measurements.

The Need for a Unified Roughness Evaluation Standard

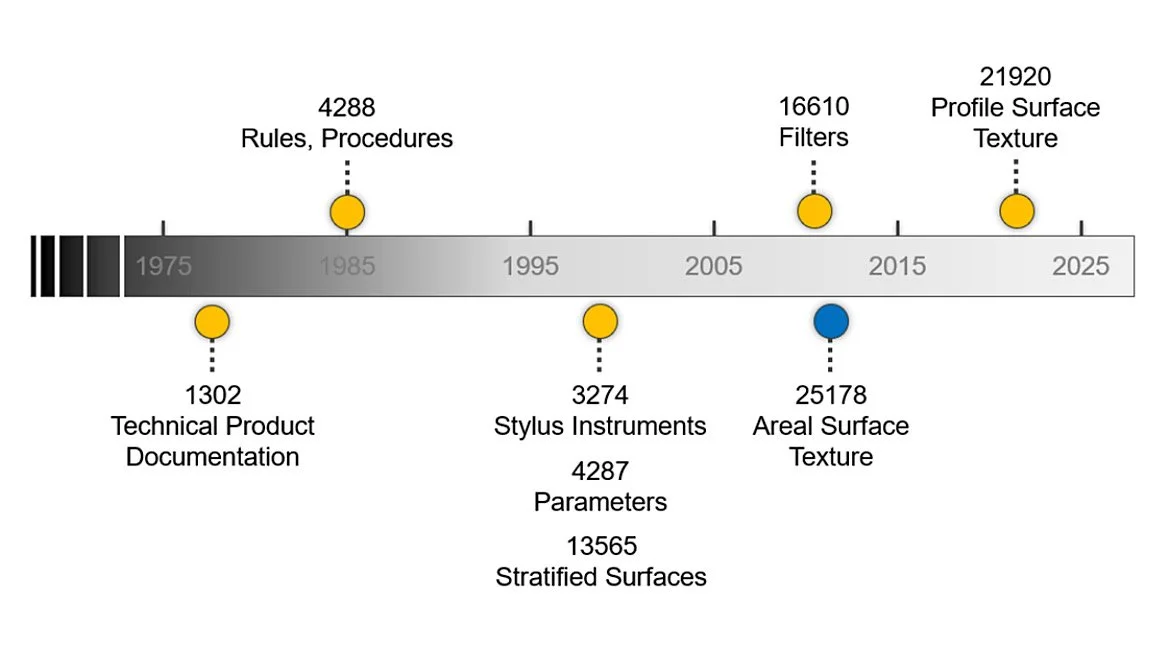

Prior to ISO 21920, practitioners had to navigate a variety of different standards including ISO 1302, ISO 4287, ISO 4288, and ISO 13565-2/-3. This scattered system often led to inconsistent interpretations and application. Moreover, critical definitions varied or were difficult to grasp without significant metrology expertise.

ISO 21920 responds to these issues with a more integrated framework divided into three parts:

ISO 21920-1: Indication of Surface Texture

ISO 21920-2: Terms, Definitions, and Parameters

ISO 21920-3: Specification Operators

Importantly, while the new standard introduces changes in structure and clarity, it does not invalidate previous designs or fundamentally alter measurement outcomes. Instead, it promotes better usability and brings it into alignment with other existing standards such as the American ASME system and ISO 25178 (areal surface parameters).

Figure 1: A timeline of ISO standards from 1975 through the present. Source: Polytec

Part 1: Indication of Surface Texture – Enhancing Clarity and Usability

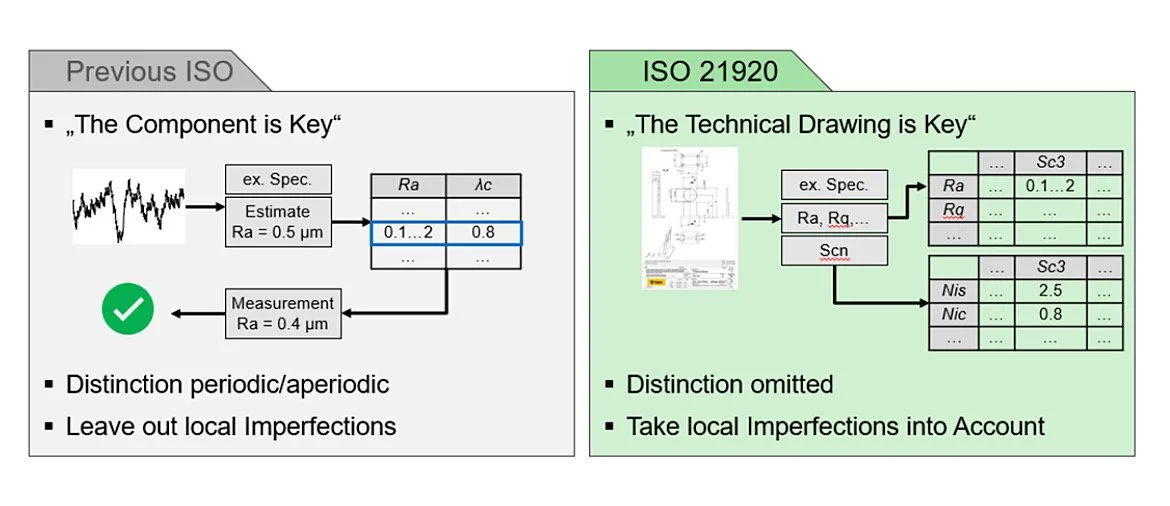

One of the biggest changes introduced in ISO 21920-1 is how technical drawings communicate surface texture specifications. This section of the standard replaces ISO 1302. The major change to this standard is that the drawing now controls not only the surface characteristics and tolerances but also the conditions for testing.

Key updates include:

Filter Specification: Engineers must either explicitly define filter settings or use a standardized setting class to dictate measurement parameters.

Default Tolerance Acceptance Rule: Unless otherwise stated, the default rule now assumes maximum tolerance acceptance. In practice, this means that even a single criteria failure results in the whole part failing. The 16% tolerance rule must now be explicitly stated.

New Graphical Symbols: A refreshed symbol system reduces ambiguity and supports additional information parameters within the symbol.

Part 2: Terms, Definitions, and Parameters – Moving Beyond Ra

As the demands for surface quality increase, it is important that the standards keep pace. Ra (arithmetical mean roughness) has long dominated roughness specification even if it is not the best standard to use. The second section from ISO 21920, ISO 21920-2,replaces ISO 4287 and ISO 13565-2/-3 by recognizing increasing surface complexity and broadens the scope of measurable and reportable parameters.

While many of the terms are retained or slightly modified, new concepts are introduced to provide a more nuanced picture of surface texture. Notable revisions include:

"Maximum Height": For better clarity Rz has been renamed from the existing term of "mean roughness depth" to "maximum height"

New Parameter Categorization: Parameters are now classified based on evaluation length or section length, emphasizing consistency and reducing unnecessary averaging over multiple sections.

Parameter Families: Expanded metrics now serve as profile-based counterparts to the areal surface parameters found in ISO 25178, enhancing compatibility and cross-standard understanding.

This development allows designers to tailor roughness specifications more precisely to the functional needs of parts. This can be especially important in applications where load-bearing, sealing, friction, or lubrication properties are critical among many other applications.

Figure 2: A brief summary of some components of ISO 21920, including the changes made to the technical drawing. Source: Polytec

Part 3: Specification Operators – Standardizing Measurement Evaluation

Perhaps the most impactful change for quality professionals lies in ISO 21920-3, which replaces ISO 4288 and seeks to eliminate user-dependent variation by defining default measurement conditions. It provides guidance on:

Default Settings: If a drawing does not specify filter or measurement settings, inspectors can rely on a defined set of defaults.

Drawing-Based Defaults: Instead of referencing component geometry, default filter settings are now determined by the surface specification on the drawing itself.

Elimination of Subjectivity: The new approach discards the old distinction between "periodic" and "aperiodic" profiles, which often relied on inspector judgment. Now, surface imperfections are to be considered in evaluation, not excluded.

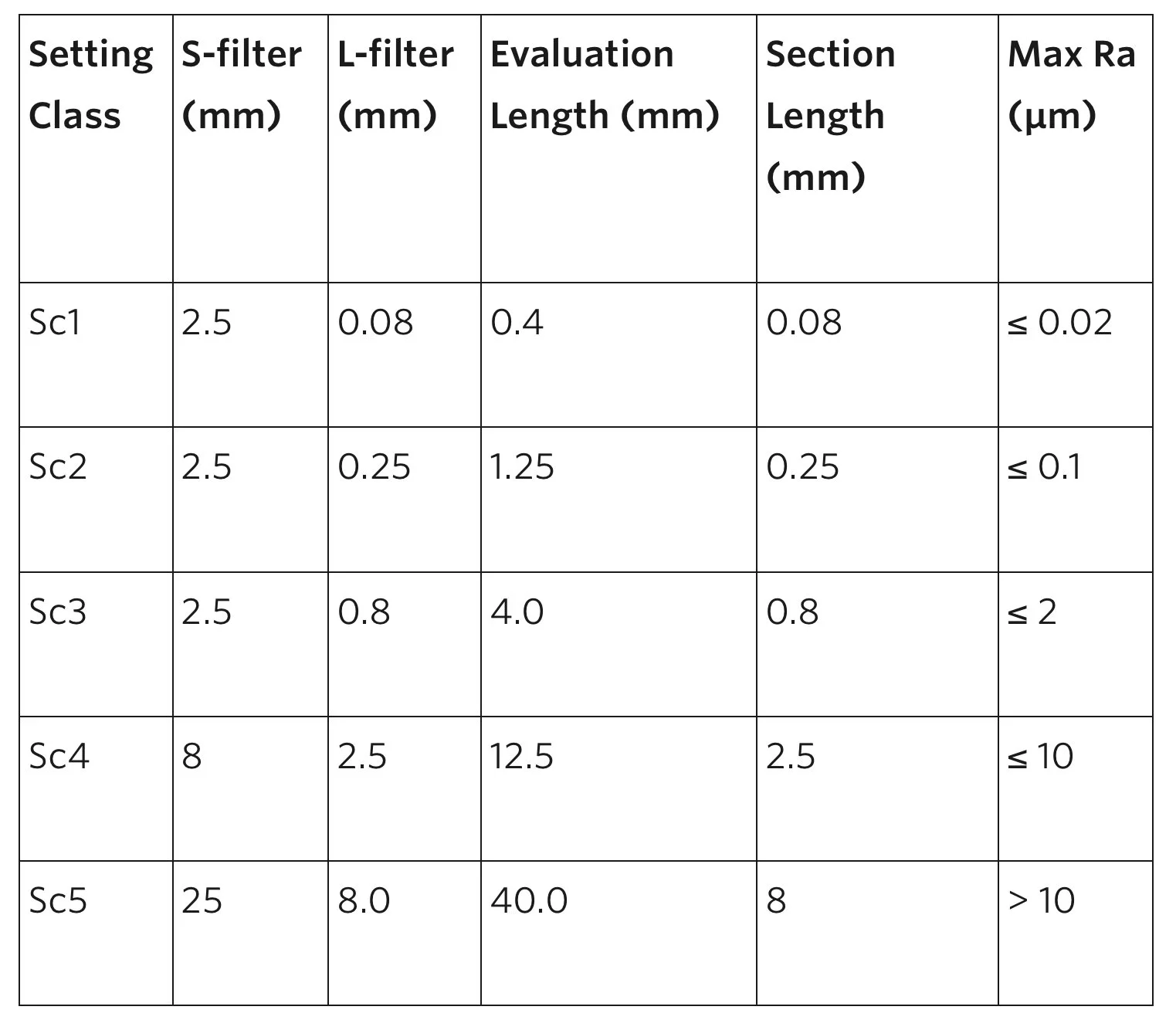

To implement this in practice, ISO 21920 introduces five Setting Classes (Sc1 through Sc5), each with preset parameters for filter types, section lengths, number of sections, and evaluation length. The table below shows the corresponding parameters for each of the setting classes. The last column shows the cutoff value for Ra for each setting class. There are many other cutoff values for surface parameters including Rq, Rz, Rp, Rv, Rzx, and Rt.

This framework standardizes how measurements are conducted and interpreted, allowing for more reliable data comparison across teams and sites.

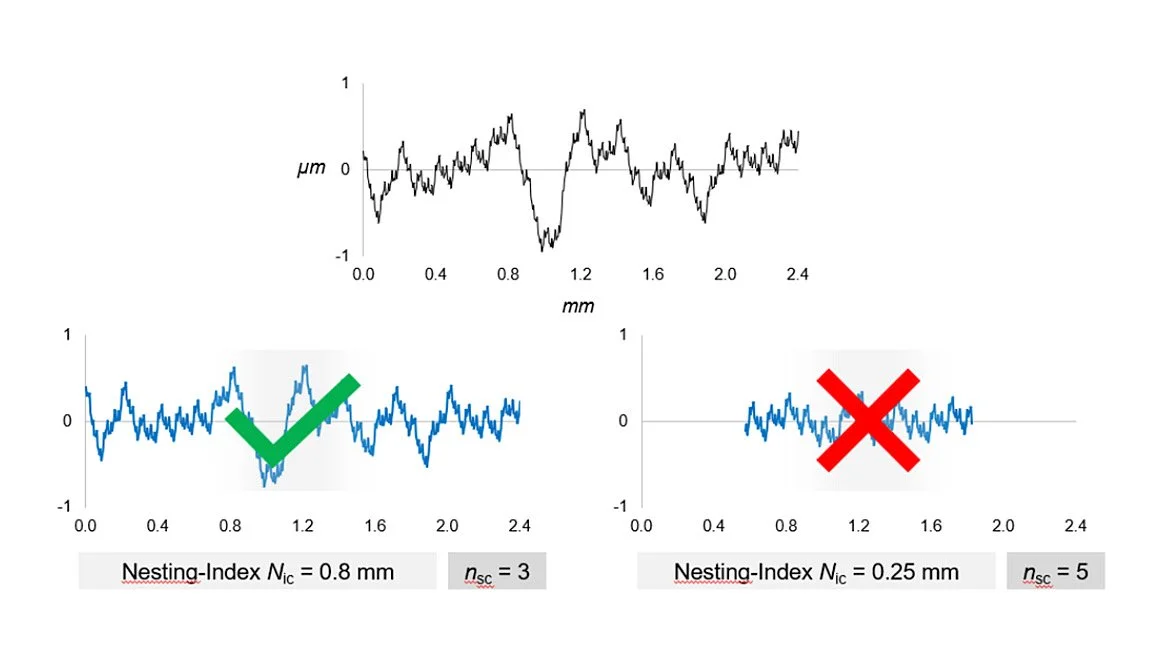

Figure 3: A quick example of how the wrong combination of nesting index and sections can lead to incorrect results Source: Polytec

Key Terms of the New Standard

ISO 21920 has some new terms to help with the definition and evaluation of roughness

Section Length (lsc): Replaces "sampling length"; a unit over which roughness parameters are calculated.

Number of Sections (nsc): Previously "number of sampling lengths."

Nesting Index (Nis Nic): A general descriptor for refinement by a mathematical model

Setting Class (Scn): Predefined groupings of measurement settings for consistent evaluation.

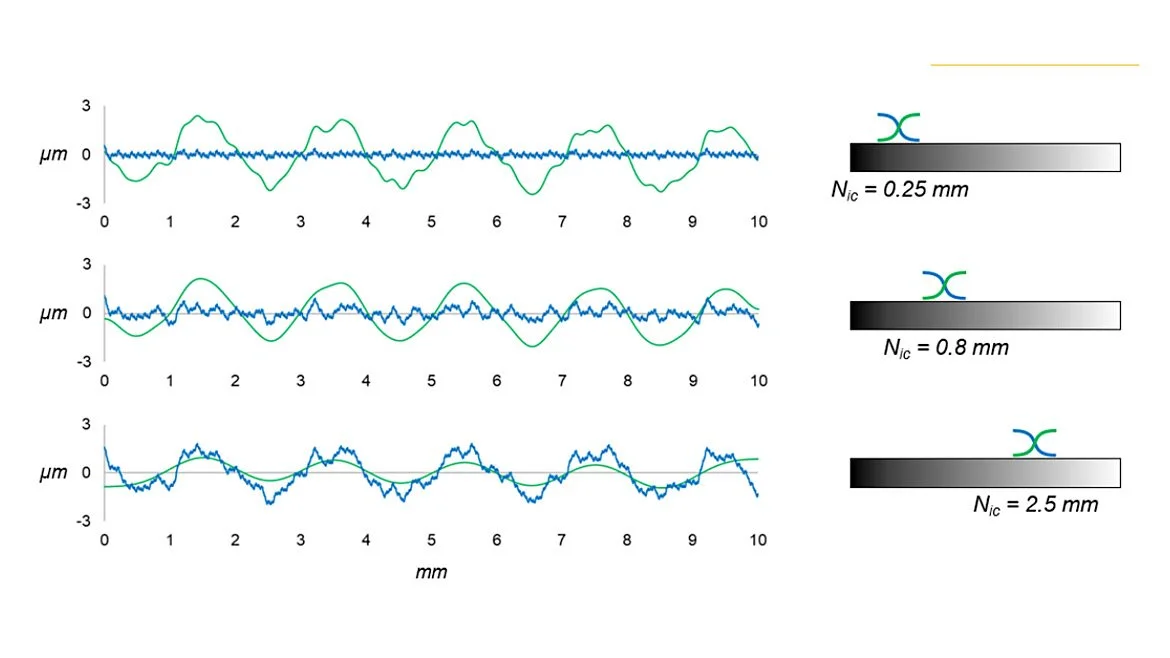

Profile-S Filter: Low-pass filter which corresponds to the waviness filter

Profile-L Filter: High-pass filter which corresponds to the roughness filter

Figure 4: An analysis of how the nesting index changes the resulting profile. Green is longer wavelength components and blue represents shorter wavelength features. Source: Polytec

Practical Implementation Considerations

For those managing the transition to ISO 21920, here are some recommendations:

Review Legacy Drawings: Existing technical drawings remain valid, but updating symbols and specifications can ease long-term integration.

Update Measurement Software: Ensure surface metrology equipment supports the setting classes and filter options outlined in the new standard.

Train Teams on Setting Classes: Consistent application of Sc1–Sc5 ensures uniform evaluations and avoids confusion.

Document Your Tolerance Rules: Clearly state whether the default maximum acceptance or 16% rule applies to avoid misinterpretation during inspections.

Conclusion: Toward a More Reliable Roughness Language

ISO 21920 marks a significant improvement in how surface roughness is defined, measured, and communicated. By aligning with international practices, incorporating lessons from decades of field experience, and offering improved clarity, it helps eliminate ambiguity and subjectivity from surface texture evaluation.

Whether you are a design engineer looking to ensure functional performance, or a quality inspector tasked with verifying compliance, ISO 21920 offers a more reliable and practical framework for surface metrology. While its adoption may require some upfront effort in training and implementation, the long-term gains in consistency, communication, and quality assurance are well worth the investment.

There are some surfaces that may be difficult to profile using ISO 21920 and 2D profilometers. Noncontact 3D profilometry techniques with use of ISO 25178 bridge the gap for seamless areal topography scanning, using efficient optical surface metrology.

Polytec Surface Metrology Team, (949) 943-3033, www.polytec.com.