You have choices, make the right choice

Is Your Quality Room The Issue When it Comes to Your Measurements

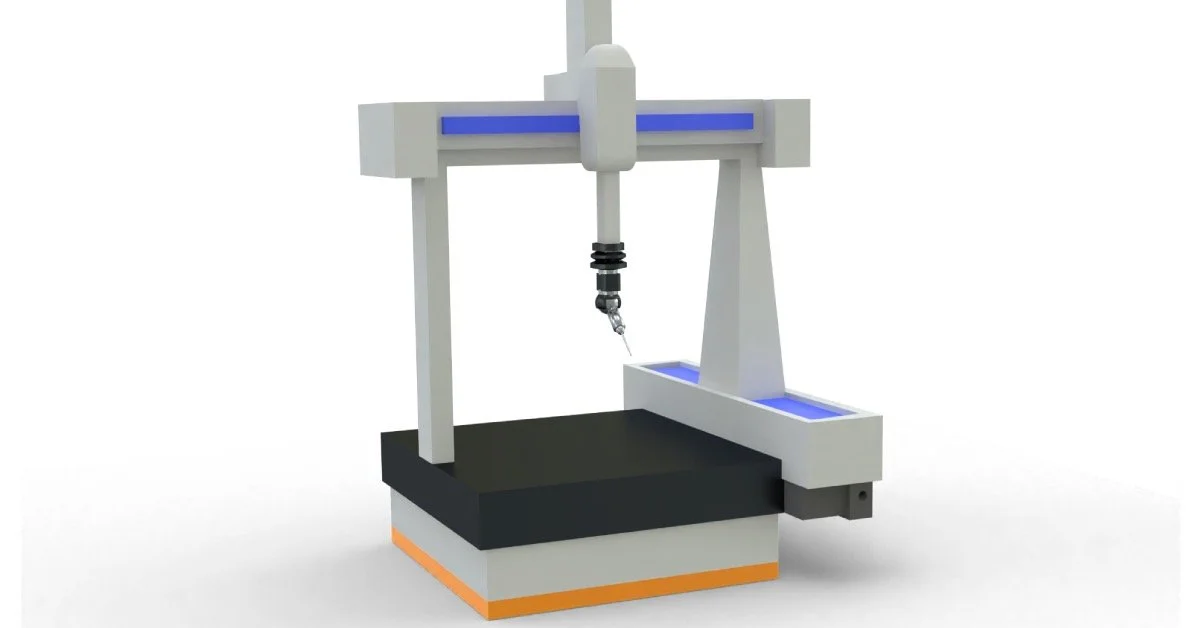

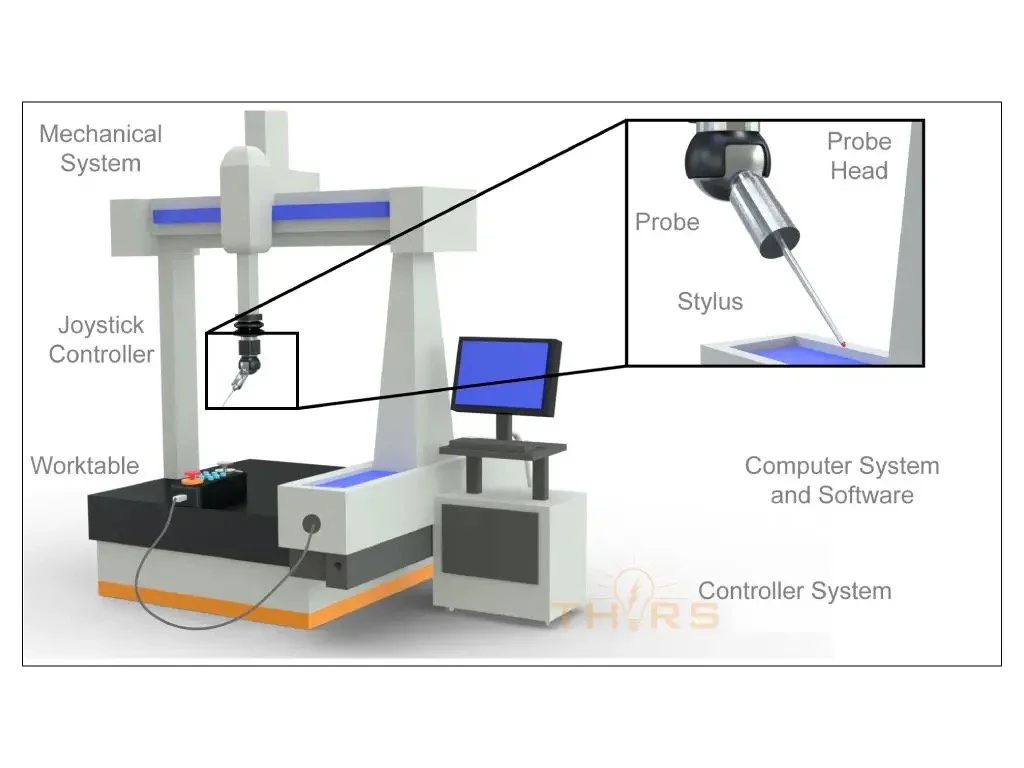

In the precision-driven world of manufacturing and quality control, Coordinate Measuring Machines (CMMs) stand as indispensable tools for ensuring dimensional accuracy and part conformity.

Ready launches ‘RUN’ – a flexible CMM for shopfloors

Italy-based Ready has introduced RUN, a new line of coordinate measuring machines (CMMs) designed specifically for use in production environments.

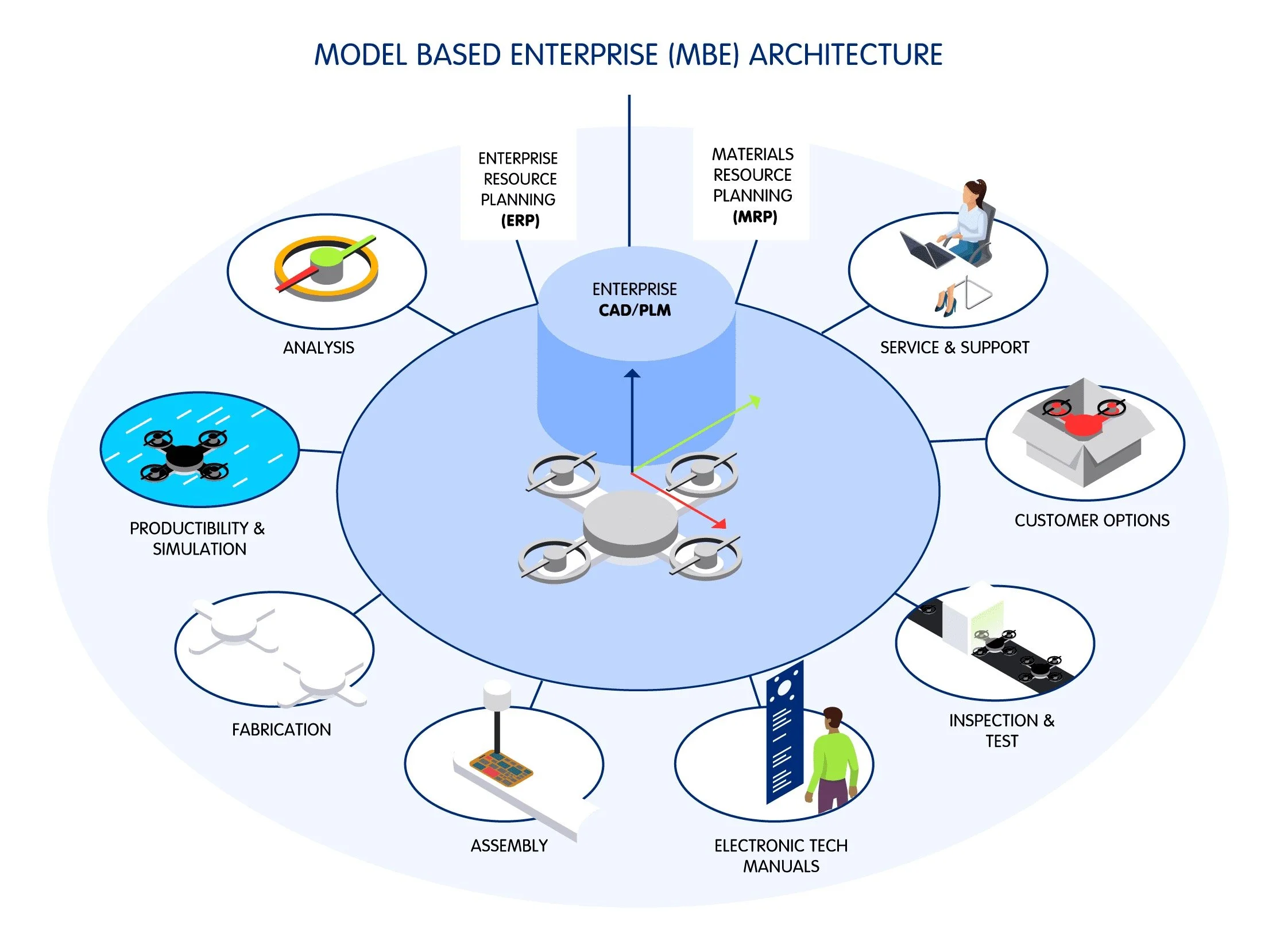

Optimizing Manufacturing and Quality Synergy: Advanced Model-Based Enterprise Strategies for Bidirectional Data Exchange

Model-Based Enterprise (MBE) has emerged as a pivotal paradigm shift, replacing traditional paper-based processes with fully digital, model-centric approaches. This transformation is driven by the need for greater efficiency, accuracy, and collaboration across the product lifecycle.

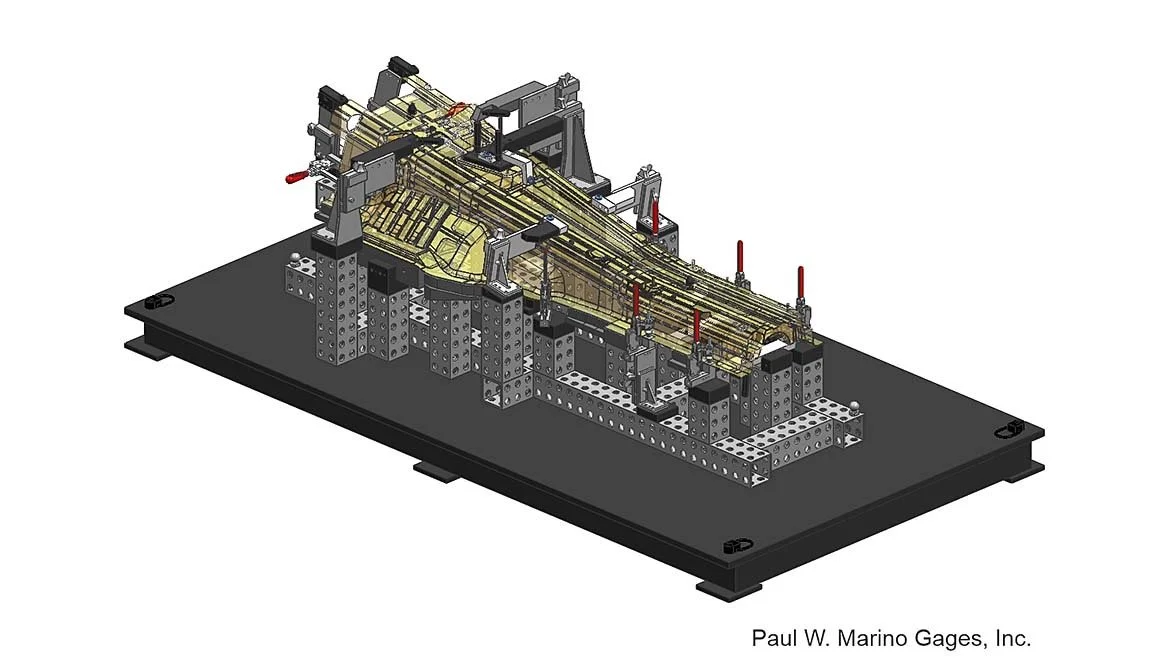

Fixtures: Traditional vs. Modular Tooling Features and Benefits

Whether it’s a small part or large, there is a modular system capable of constructing a reusable, reconfigurable fixture.

3 Project Planning Recommendations to Ensure QMS Development Success

Looking to improve the efficiency of inspection management, CAPA management, and other quality control processes, companies across industries are increasingly investing in implementing quality management systems.

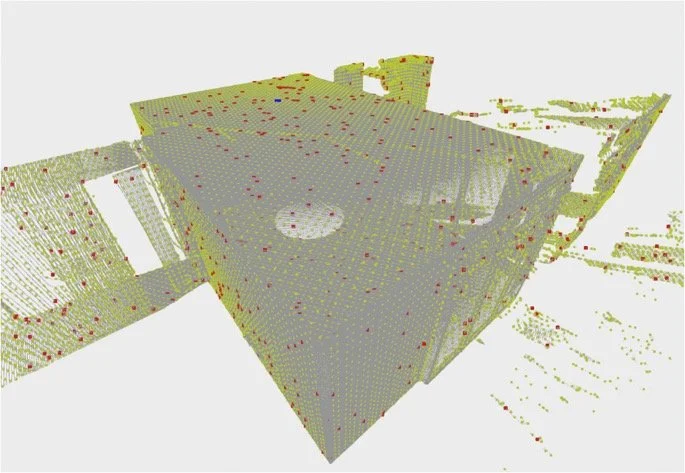

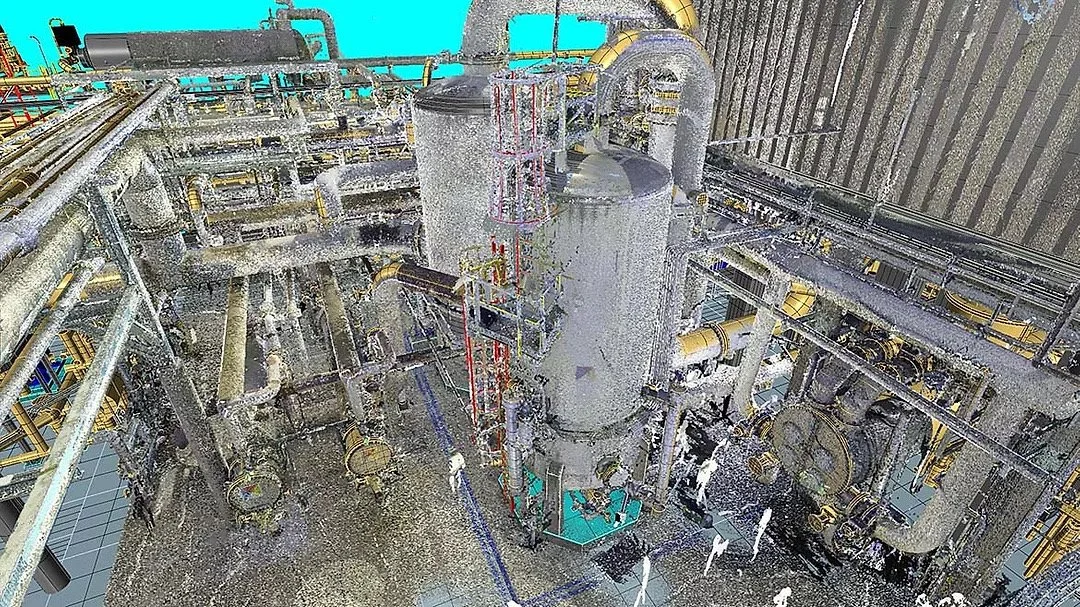

Understanding the GUM Methodology: Applications to Point Clouds in Coordinate Metrology

In the field of coordinate metrology, where precision is paramount, the accurate assessment of measurement uncertainty is essential for ensuring reliable results. The Guide to the Expression of Uncertainty in Measurement (GUM) provides a standardized framework for evaluating and expressing this uncertainty. Developed collaboratively by international metrology organizations, GUM has become the cornerstone for uncertainty analysis across various measurement disciplines, including those involving coordinate measuring machines (CMMs) and 3D scanning technologies.

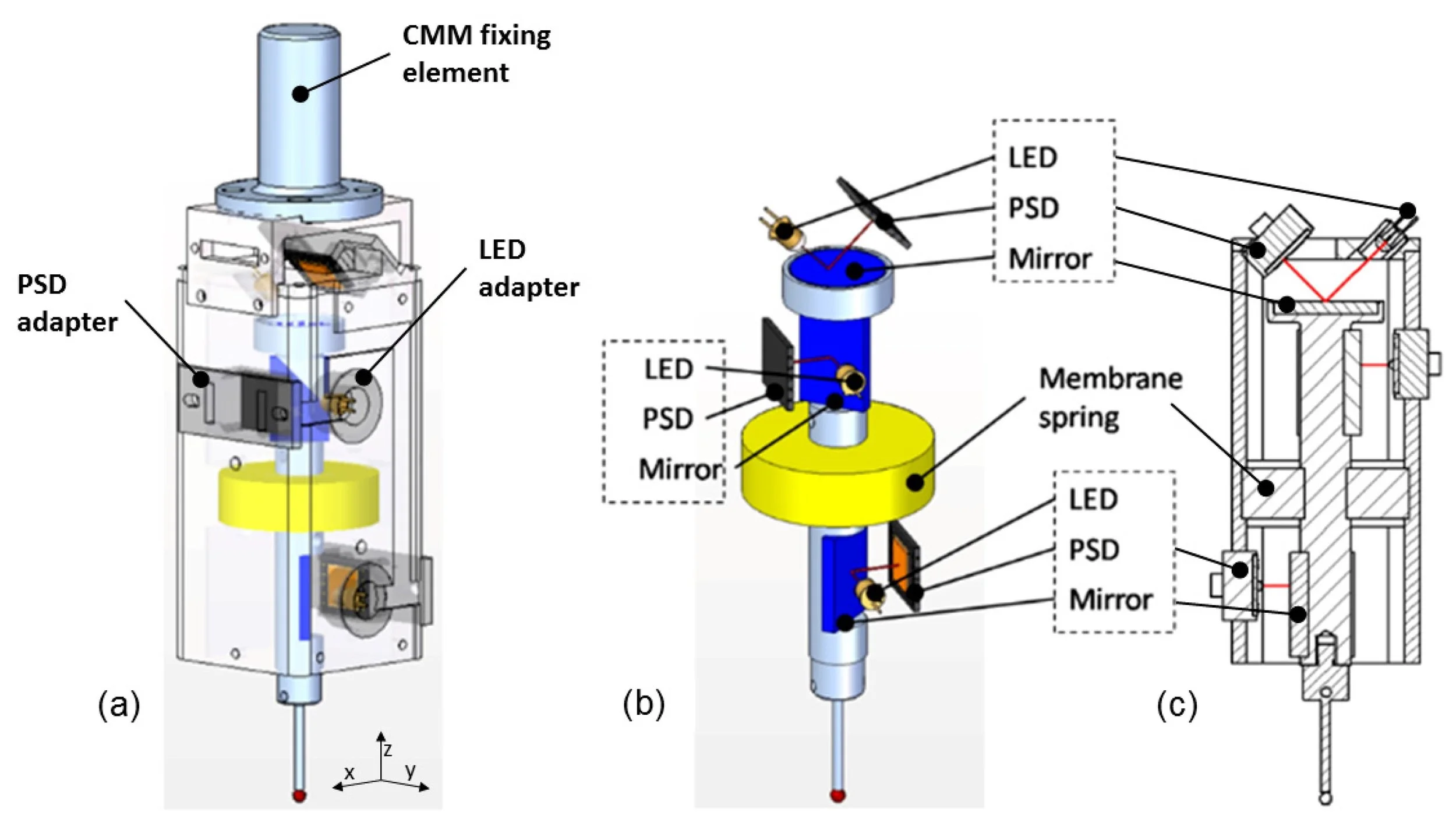

Measuring Force of Scanning Probes of Coordinate Machines

Coordinate measurement technology is a cornerstone in industries like automotive, aviation, and precision manufacturing. The authors note: “The number of coordinate measuring machines (CMM) operating in measurement laboratories and production halls is constantly growing.

Hybrid Machine Learning Framework for Predicting Geometric Deviations from 3D Surface Metrology

This article is a rewritten summary of the original research paper by Hamidreza Samadi, Md Manjurul Ahsan, and Shivakumar Raman from the University of Oklahoma.

ZEISS celebrates 100 years of advancing innovation in the U.S.

Today, ZEISS marks 100 years of operation in the U.S., helping Americans improve lives and reach profound achievements by applying the company’s innovative technologies to research, healthcare, manufacturing and more

Understanding ISO 10360 Standards for Coordinate Measuring Machines

The ISO 10360 series is an international set of standards developed by the International Organization for Standardization (ISO) to specify acceptance and reverification tests for Coordinate Measuring Machines (CMMs).

Understanding ASME B89.7.2: Dimensional Measurement Planning in Precision Metrology

In the field of precision metrology, ensuring the accuracy and reliability of dimensional measurements is paramount, particularly when using advanced tools like Coordinate Measuring Machines (CMMs).

What a True Digital Twin Is—and What It Isn’t

The phrase “digital twin” is everywhere these days, but it’s also widely misunderstood. Ask ten people what it means, and you’ll likely hear ten different answers. Many assume it’s simply a CAD model or a 3D scan. Those are important tools, but they’re not the whole story.

Education, Metrology and Manufacturing in Sync

Vincennes University, Vincennes, IN, a flagship HTEC (Haas Technology Education Center) and Flying S Inc, Palestine, IL, are an example of education working in lockstep with a real-world industry partner.

Kaizen Explained in Detail

Kaizen (改善) = Kai (change) + Zen (good) → Change for the better

or more commonly translated as Continual Improvement.

It is both a philosophy and a practical method.

Metrology Trends: Turning Precision into Performance

Precision has long been the backbone of manufacturing. But today, precision alone no longer guarantees performance.

ASME Y14.41: Pioneering Model-Based Definition in Modern Metrology

In the evolving landscape of manufacturing and engineering, the shift from traditional 2D drawings to fully digital, model-centric approaches has revolutionized how products are designed, produced, and inspected.

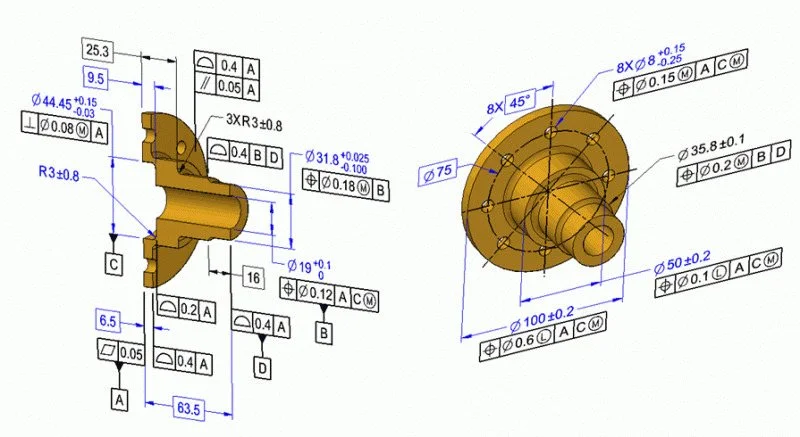

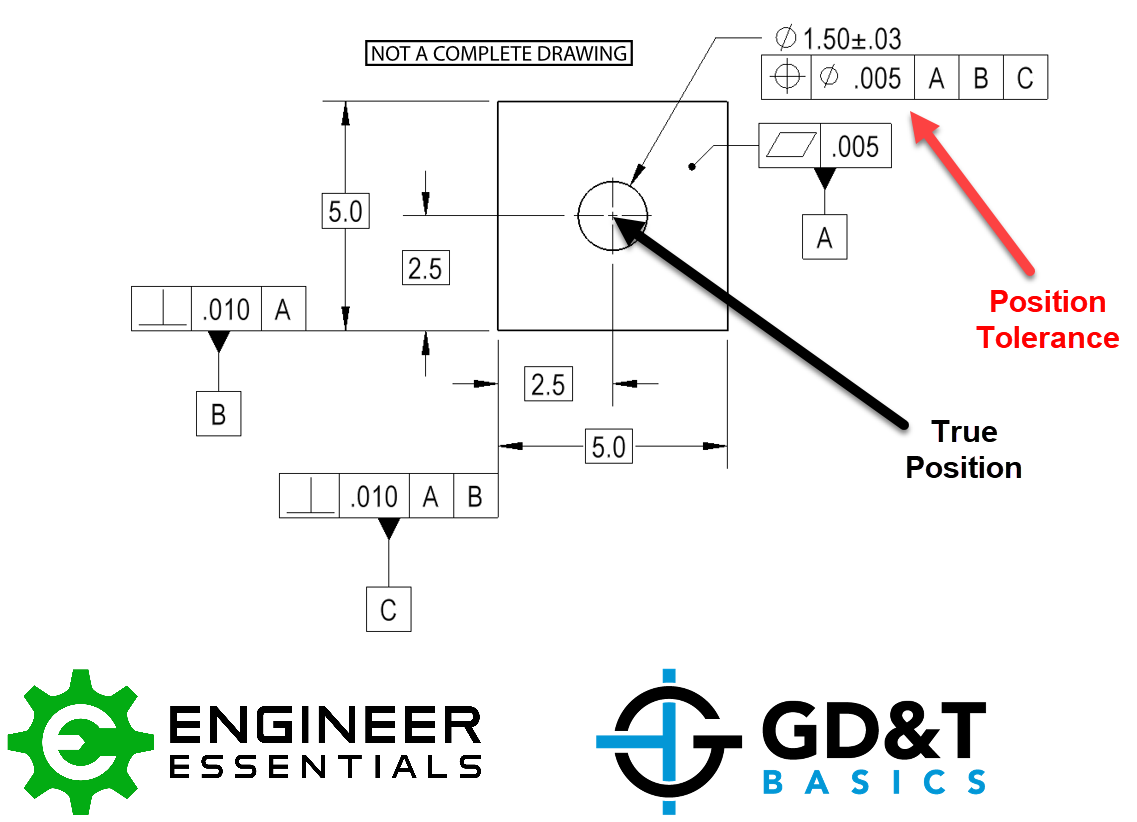

Understanding ASME Y14.5.1: Mathematical Definitions of Geometric Dimensioning and Tolerancing

In the precision-driven world of metrology, where Coordinate Measuring Machines (CMMs) and advanced inspection technologies ensure parts meet exacting standards, Geometric Dimensioning and Tolerancing (GD&T) serves as the universal language for defining and communicating engineering tolerances.

How IA9101 and IA9104/1 Are Reshaping AS9100 Aerospace Quality Management

The introduction of IA9101 and IA9104/1 represents the largest adjustment to aerospace quality management certification in recent years.

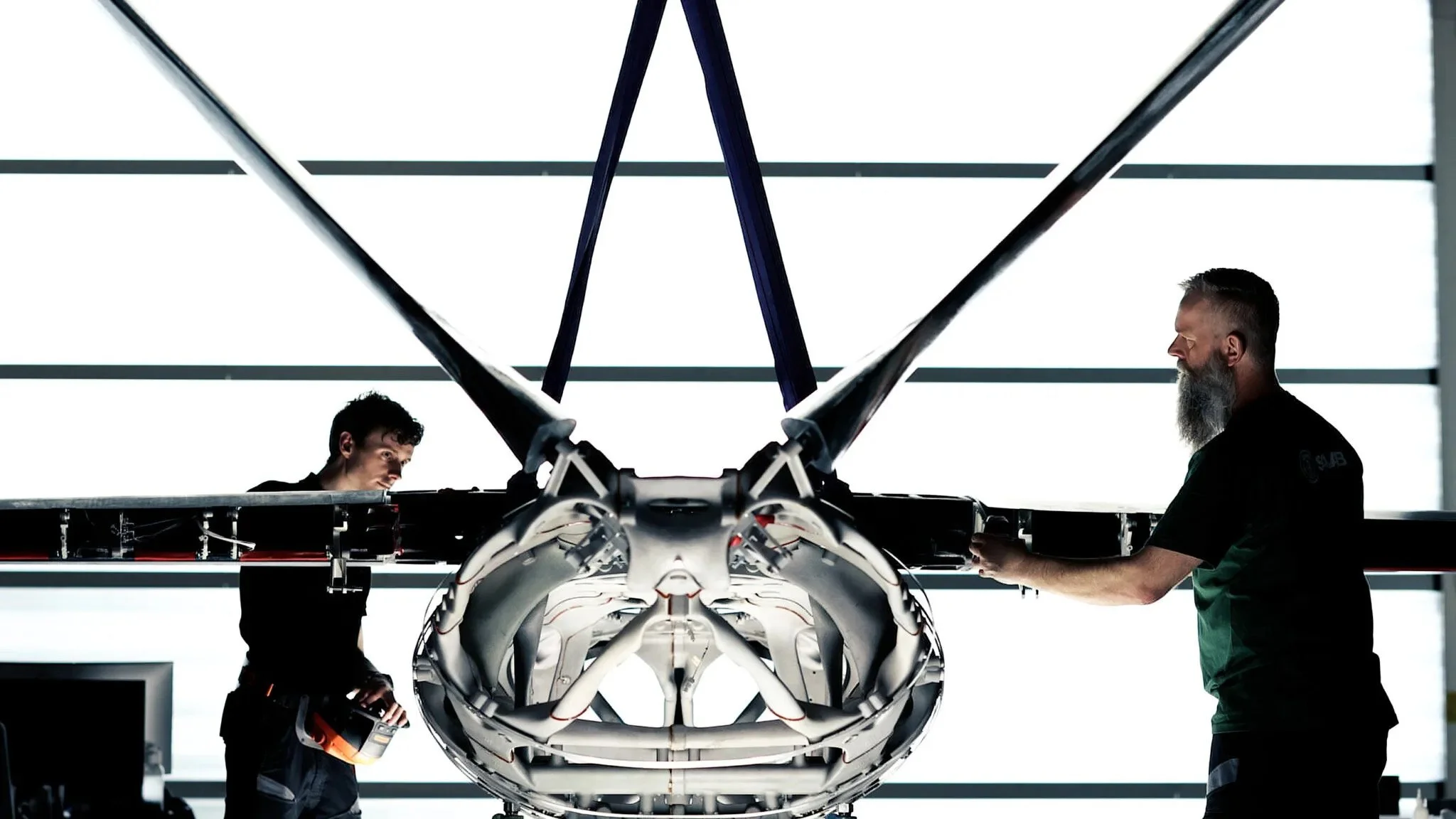

Saab and Divergent 3D print large fuselage

Saab and 3D printing company Divergent have used additive manufacturing to produce one of the largest fuselages ever for powered flight.

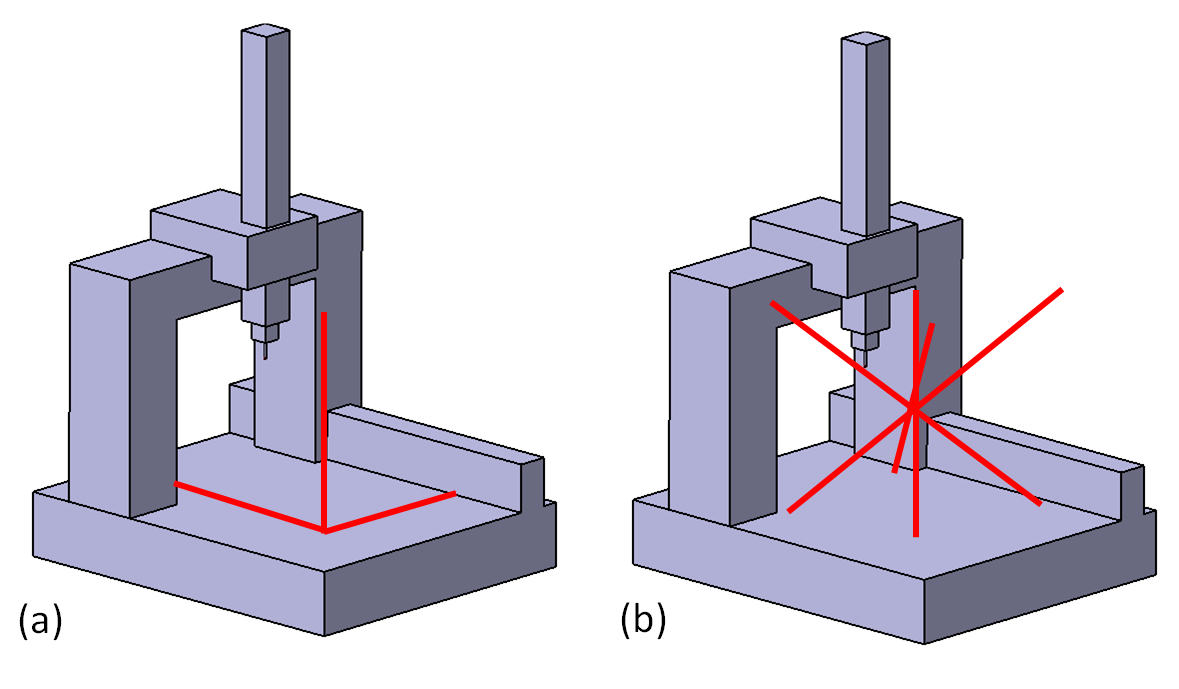

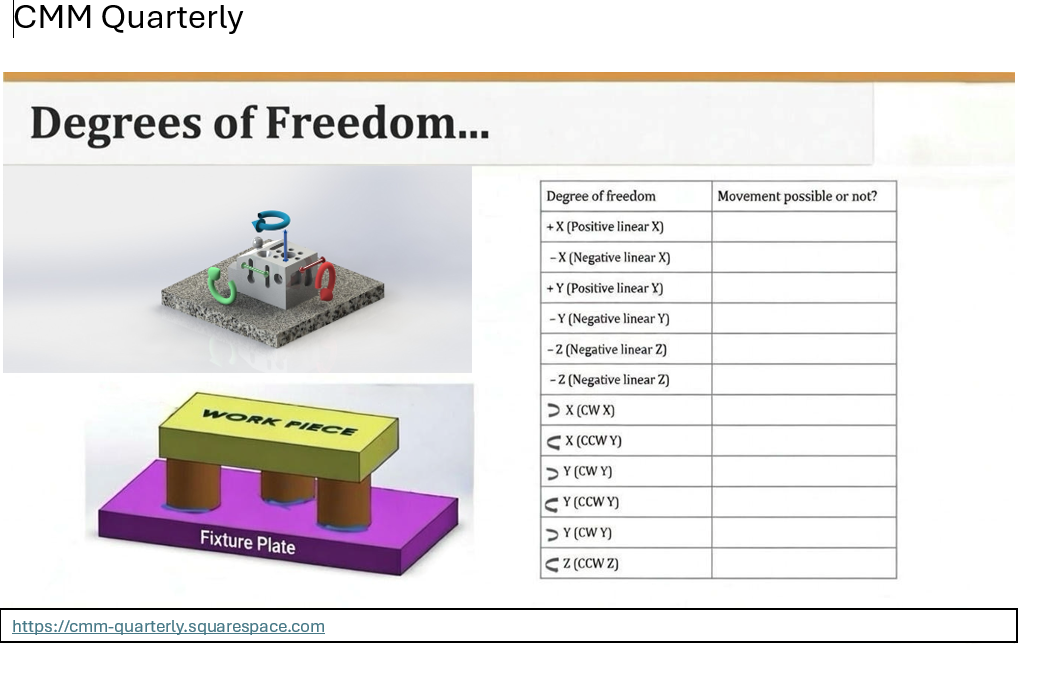

Degrees of Freedom Checklist

In the world of Coordinate Measuring Machine (CMM) programming, accuracy begins long before a probe touches a part. The foundation of every precise measurement is fixturing. To measure a part accurately and repeatably, a programmer must first understand how to physically and mathematically "lock" that part in space. This process is known as constraining its Degrees of Freedom (DOF).