Coordinate measuring machines hit the target for weapons standards

Discover how coordinate measuring machines ensure tight tolerances, traceability, and quality control in mission-critical defense and weapons system manufacturing.

Gene Hancz - CMM product manager for Mitutoyo America Corp.

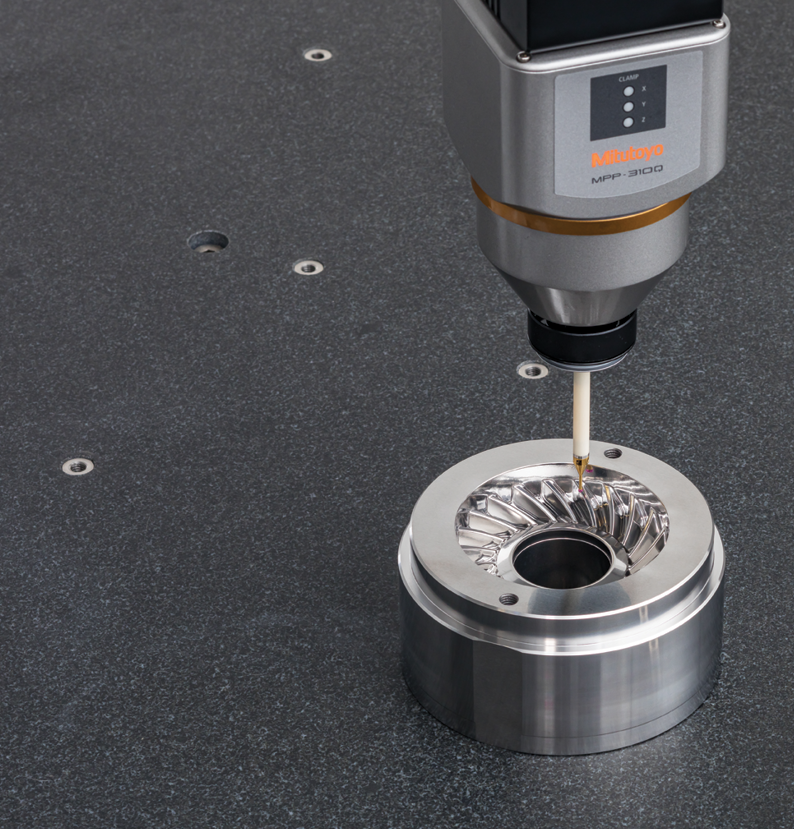

Different CMM probes allow for highly accurate measurements on a variety of complex, critical parts often found in defense and munitions manufacturing. Having these options to measure with precision using just one machine exemplifies the versatility and value of CMMs in the defense industry.

PHOTOS COURTESY OF MITUTOYO AMERICA CORP.

In weapons systems manufacturing, one imprecise part can compromise an entire system – and an entire mission. That’s why there are no standards quite like defense standards, and why weapons system manufacturers must ensure precise parts measurement, particularly in barrels, firing mechanisms, and triggers. Tight tolerances guarantee consistent performance and are key to the success of mission-critical applications and protecting the lives of on-the-ground crews.

Coordinate measuring machines (CMMs) are a vital technology, allowing defense manufacturers to maintain strict part tolerances more efficiently and reliably. By measuring geometries of physical parts and comparing them to specified design parameters, CMMs help identify even the smallest deviations, ensuring finished weapon components function exactly as intended.

In defense, precision is non-negotiable

While component precision is important across all industries, it’s especially critical in defense. Consider a smaller firing mechanism. The trigger releases a striking device (such as a hammer) which then strikes a firing pin, which strikes a primer causing ignition and ejection. This chain of events requires precision within 0.020". But there’s minimal room for error even in larger weapon systems. A GPS-guided 155mm Howitzer system typically has only 4m or less of wiggle room around the target point.

Weapon systems must also operate in harsh environments, such as combat zones, unforgiving climates, and rugged terrain. When parts are exposed to extreme stress, even the smallest deviations can compromise structural integrity and performance. A catastrophic failure can cause significant loss of life and property. Even smaller malfunctions incur the costs of rework, material resources, and potential legal liability. And then there are the soft costs, such as production delays and brand reputation.

What is a coordinate measuring machine, and what types are available?

A CMM is a large, heavy-duty industrial device measuring the geometry of physical objects (angles, curves, distances) by using a probe to sense points on the object’s surface and then compare them against the part’s intended specifications. Today’s CMMs replaced manual gages and feature automated data collection and integrated CAD files for the fastest, most accurate component measurement. Types of CMMs include:

Bridge: a bridge structure supports the probe for efficient, precise measurement of medium to large components. The most widely used CMM.

Gantry: a larger bridge and wide bearing base measure the largest and heaviest parts (such as an aircraft fuselage) with a high degree of precision.

Cantilever: a single vertical probe support offers a large measurement range in a compact device.

Portable: hand-held device performs dimensional measurement at the original location, offering flexibility for prototyping or quick inspections.

Why CMMs excel in defense weapons systems

Modern CMM software can support PMI data and advanced CAD interoperability streamlined digital thread initiatives in the defense and munitions industry by reducing reliance on 2D drawings, minimizing human error, and accelerating production and compliance to help defense contractors meet stringent quality and performance demands.

CMMs are an ideal solution for weapons system measurement to identify any deviation from specs. In weapons systems, even the smallest error can have an outsized effect on performance and safety.

Micron-level precision – The CMM’s probe moves along three axes – X, Y and Z – orthogonal to each other in a three-dimensional Cartesian coordinate system. Each axis has a sensor monitoring the position of the probe on that axis, with a high degree of accuracy on the level of microns, or one-millionth of a meter (too small for the naked eye). To appreciate the smallness of microns, a human hair is about 100 microns.

Automated data collection for high volume production – Automated, rapid data collection and analysis software in CMMs speeds development, enabling high-volume production and faster delivery for urgent, mission-critical operations. CMMs can alert manufacturers to design nonconformances and trends as soon as they occur, ensuring precise, reliable production and a more efficient product life cycle.

Traceability and documentation – Robust traceability is essential for defense manufacturers who must prevent illicit transfer, comply with defense industry standards, and quickly isolate and stop defects. CMMs centralize component information that can be linked to specific part serial numbers, batches, or measurement runs. For example: “When and where was the part made? What is the maintenance and inspection history?” CMMs also maintain a database to answer any question in the event of an audit or documentation request.

Critical weapon components demanding CMM precision

Barrels: Internal diameter, straightness, and smoothness of the barrel are crucial for accuracy because projectiles must leave the barrel in a straight line. Straightness also helps align rifling for consistent spin, while surface smoothness reduces barrel friction for maximum velocity.

Firing mechanisms: Tight tolerances are essential for the set of small, intricate parts and safety features to function together for safe and accurate ignition and ejection.

Triggers: Consistent trigger pull weight ensures safety, reliability, and accuracy, especially in precision shooting applications and under challenging conditions. A pull weight that’s too light or too heavy can risk accidental discharge

Benefits of using CMMs for weapons system measurement

Today’s CMMs offer a host of benefits, taking parts measurement to a new level of precision and speed never possible with manual methods. They’ve become an essential business technology in the following areas:

Increased accuracy, repeatability – CMMs offer measurement accuracy within the range of microns (0.001mm), account for temperature effects on materials, and apply data analytics, ensuring every single part coming off the line matches the design plan. Manufacturers can promise repeatability and consistency across multiple production batches.

Efficiency, productivity – Advanced CMMs operate at speeds tripling or even quadrupling the throughput of older machines and methods, moving at 250mm/second. Combine that speed with automated measurement workflows and real-time data integration, and manufacturers can speed inspection processes and scale up production. Earlier, faster corrective actions improve efficiency and reduce costs.

Improved quality control and compliance – Faster, more precise measurement means consistent, higher quality, fully compliant weapon parts and systems. A CMM’s database provides detailed inspection reports and histories to meet stringent defense regulations and ensure easy traceability for future reference and audits.

The path to successful CMM implementation in weapons manufacturing

CMMs are ideal for measuring different dimensions such as inner and outer diameters of these blank rifle barrels. With optional probes, a CMM can determine if surface roughness parameters are within spec before sending the barrel to rifling and finishing.

A thoughtful and strategic approach to CMM implementation maximizes their full value. It begins with choosing a CMM using advanced metrology software to provide digital part plans along with critical data analytics and traceability reporting. Next, expert installation and setup ensure the right location and proper fixture and part orientation (such as air bearings, bridge placement), minimizing movement and vibration that can affect results.

Calibration and maintenance are also key, with most CMM manufacturers recommending maintenance checks and factory calibration after 2,000 hours of operation and then following a set schedule to meet standards. It’s also important to learn the relationship between what you’re measuring and the CMM’s components. A stylus ball, for example, might wear differently depending on the parts being produced. Finally, maintaining proper environmental controls reduces maintenance issues and ensures accurate measurement of materials susceptible to changes in temperature.

CMMs offer next-level weapons measurement – but what are the challenges?

The precision CMMs bring to large-volume, highly regulated weapons measurement requires highly advanced technology and a corresponding high initial investment. It’s important to balance the cost with the considerable longevity of the machines and the potential savings from improving manufacturing quality, capabilities, production efficiency, and defense industry compliance. CMMs also require specialized training to operate and knowledge of product tolerances and measurement. However, much of the information required is integrated within the CMM’s software and there’s increasingly less burden on operators.

New challenges and benefits may arise as CMM development continues. Emerging technologies include advanced probing systems for a wider range of applications. Optical CMMs, or vision machines using image processing without contact may play a bigger role in weapons systems as parts require more delicate measurement at the sub-micron level. At the same time, CMMs will likely be integrated further into smart manufacturing plants and processes. Artificial intelligence (AI) and machine learning (ML) will enhance the already robust data features of CMMs, predicting and optimizing their features.

Conclusion

CMM technology provides micron-level 3D precision measurement and speed essential for weapons production accuracy, repeatability, and operator safety. It meets the high bar set by defense standards and regulations while keeping production efficient even at high volumes.

But CMM precision isn’t just a safety or budgetary issue, it’s a strategic business decision as well. CMMs can make weapons systems more effective than previous design iterations and enhance business capabilities. Weapon design and accuracy is constantly evolving, and CMMs can help manufacturers build and maintain a competitive advantage and prepare for the design changes and AI-driven factories of the future.