You have choices, make the right choice

Mitutoyo MCOSMOS: Harnessing CAD-Driven Metrology

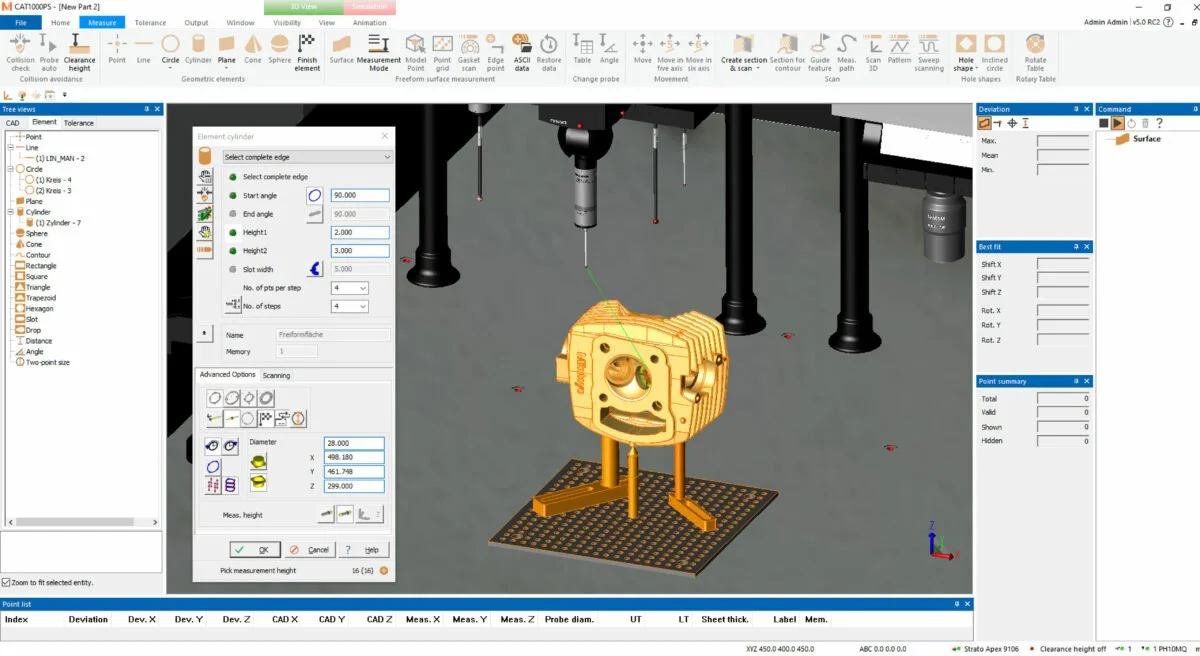

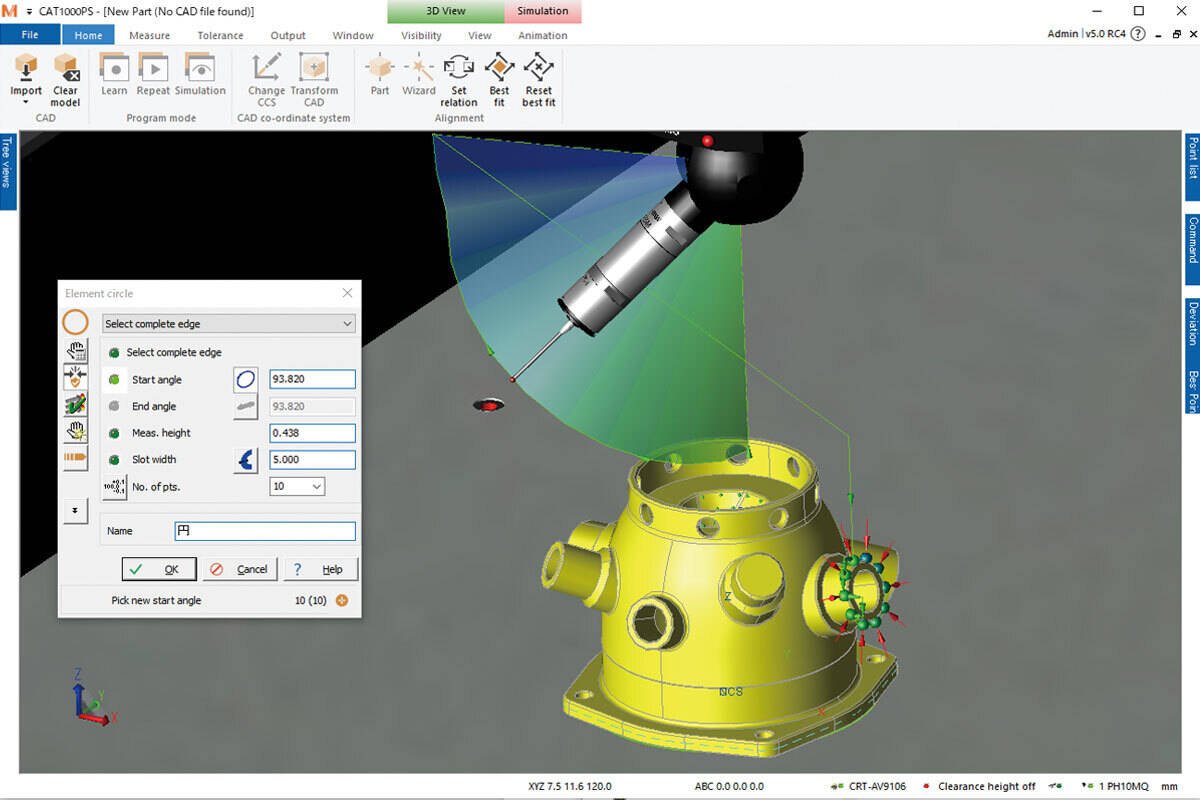

Mitutoyo’s MCOSMOS is the industry-leading metrology software suite that transforms a coordinate measuring machine into a fully integrated, CAD-driven inspection environment. At its heart lies PartManager, the command center that organizes all measurement tasks, data, and reports.

Mitutoyo America Corporation Releases MCOSMOS V5.4 Advanced Metrology Software Suite for Coordinate Measuring Machines to Improve Measurement Efficiency

Mitutoyo America Corporation, the leader in metrology instruments, solutions and support, announces the release of MCOSMOS V5.4, the latest version of advanced metrology software suite for coordinate measuring machines (CMMs). This update improves CMM operability with faster setup, reduced downtime, improved measurement throughput giving you the competitive advantage in digital manufacturing.

Coordinate measuring machines hit the target for weapons standards

In weapons systems manufacturing, one imprecise part can compromise an entire system – and an entire mission. That’s why there are no standards quite like defense standards, and why weapons system manufacturers must ensure precise parts measurement, particularly in barrels, firing mechanisms, and triggers.

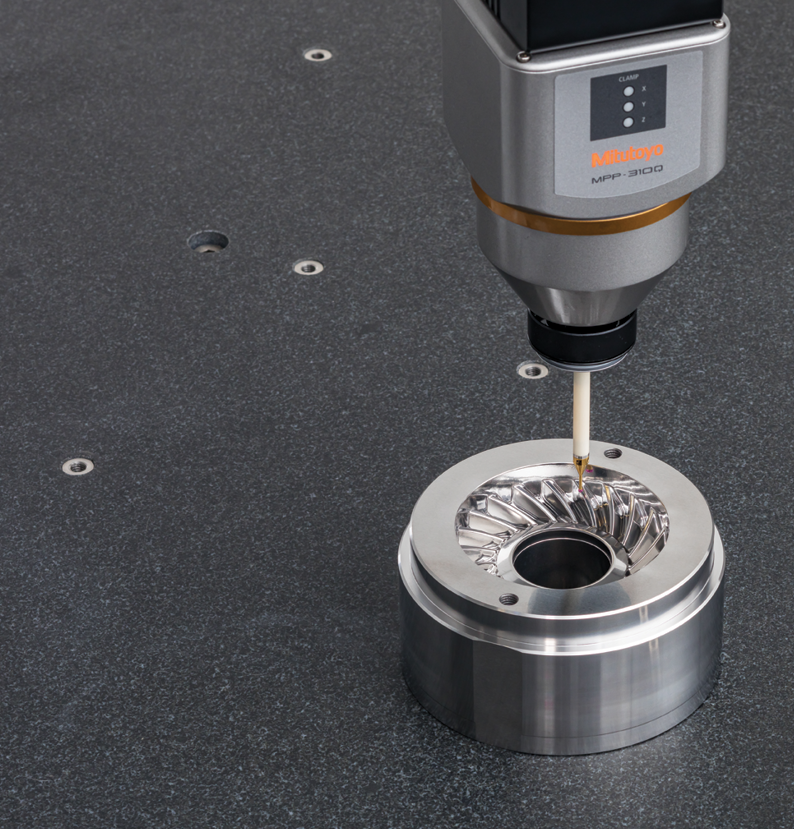

EXPAND YOUR CMM’S CAPABILITIES

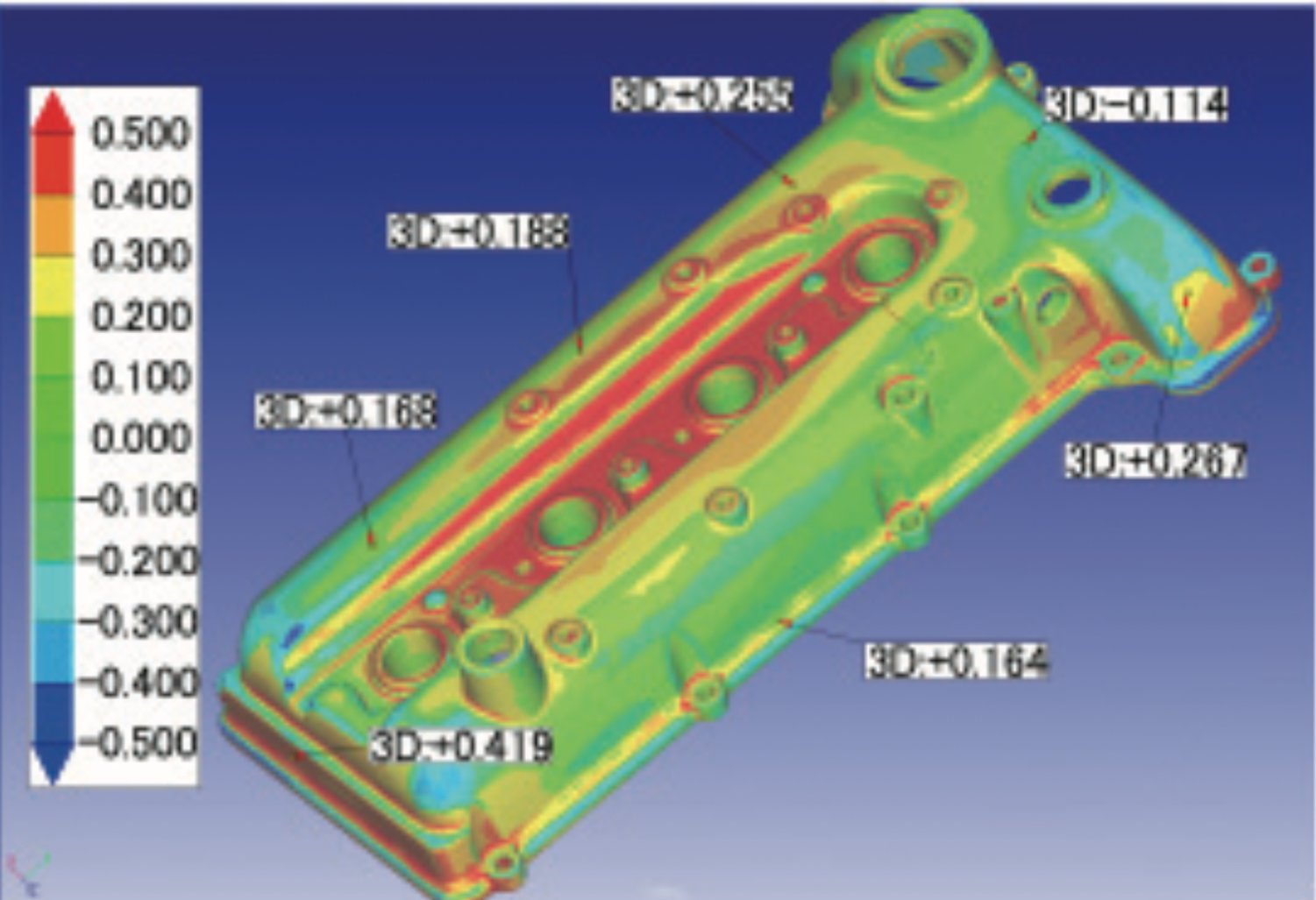

During the past 25 years, coordinate measuring machine (CMM) sensor technology has expanded from tactile and scanning systems to now include optical, laser and surface finish sensors, effectively expanding the CMM’s capabilities. While each CMM sensor technology has its own advantages and limitations, the expanded measuring capability provided to the CMM compels anyone with measuring requirements to consider adding additional sensor technology to a current CMM or for a new CMM purchase.

Advances In Model-based Measurement Can Reduce CMM Programming Time

With more man-hours being spent on programming work, differences in worker-created measurement programs, and inefficient programs being created due to proficiency issues, the industry has moved from 2-D drawings to 3-D annotated models. A number of factors—the increased emphasis on quality control, the growing diversity of parts and components being measured, the development of more complex global supply chains and reduced product lifecycles—have led to a considerable demand for automatic measurement programming in recent years.

Added MCOSMOS C1 v4 Manual

We have added a MCOSMOS C1 version 4 training manual to our products.