DISCUS CMM: Bridging CMM Data and AS9102 Reporting

By Mark Boucher

In modern manufacturing, the pressure to produce accurate, fully traceable inspection results has never been greater—especially in the aerospace and defense industries. DISCUS CMM software has emerged as a powerful tool for streamlining the flow of Coordinate Measuring Machine (CMM) data into AS9102 First Article Inspection (FAI)documentation. With its tight integration between inspection results and quality forms, DISCUS is helping quality engineers reduce manual transcription errors and cut inspection documentation time by up to 80%.

What is DISCUS CMM?

DISCUS CMM is part of the DISCUS Software Suite, a collection of tools designed for manufacturers and suppliers to simplify and automate First Article Inspection (FAI), Production Part Approval Process (PPAP), and other compliance documentation. The CMM module specifically helps import, parse, and map results from CMM output files—like those from PC-DMIS, CMM Manager, and Calypso—to their respective drawing balloon characteristics.

“DISCUS CMM has significantly cut down our data entry time. What used to take a full day now takes under an hour,” says Jennifer McNeill, Quality Engineer at AeroTech Components.

Key Features

Smart Parsing

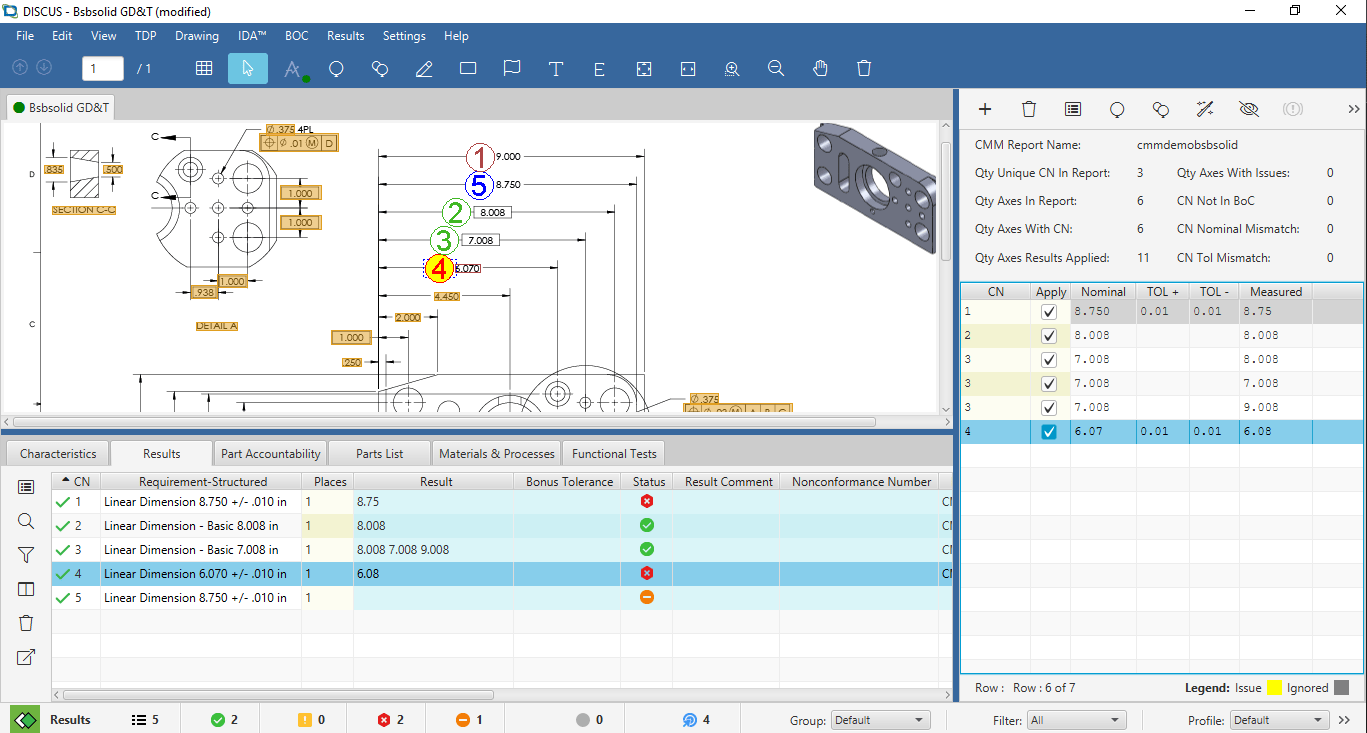

DISCUS CMM intelligently reads CMM output files and matches results to inspection requirements. Users can customize parsing profiles to fit their specific CMM format.

Seamless AS9102 Integration

All measured values can be automatically mapped to the corresponding characteristics in DISCUS Planner, filling out AS9102 Form 3 with minimal manual input.

Visual Feedback

Ballooned drawings within DISCUS provide a clear visual link between the CAD/drawing callouts and the imported measurement data.

Support for Multiple Formats

DISCUS CMM supports output from major CMM software, including:

PC-DMIS (

.txt,.xls,.csv)CMM Manager (

.txt,.xml)Calypso (

.pdf,.csv)Modus, PowerInspect, and more

The Value to Manufacturers

The value of DISCUS CMM lies in its traceability, speed, and accuracy. By minimizing human interaction between measurement output and final inspection documents, the software helps avoid costly errors and ensures that audits pass with flying colors.

“With DISCUS CMM, we’ve reduced our first article processing time by over 70%. It’s become an essential part of our quality system,” says Tom Castillo, Director of Quality at Precision AeroFab.

Who Should Use It?

Aerospace & Defense Manufacturers

Medical Device Suppliers

Automotive OEMs

Contract Manufacturers

Any company responsible for submitting documented dimensional inspection results—especially in AS9102 format—can benefit from DISCUS CMM.

Licensing and Support

DISCUS CMM is available as an add-on module to the core DISCUS desktop software. It’s licensed per user, with support packages available including onboarding and custom parser configuration.

Final Thoughts

DISCUS CMM is not just a plug-in—it’s a game-changer for manufacturers striving for compliant, efficient, and error-free inspection reporting. As quality demands increase, tools like DISCUS CMM will continue to play a critical role in reducing risk and improving productivity.

Want to Learn More?

Visit https://www.discussoftware.com or request a demo to see how DISCUS CMM can streamline your inspection processes.