You have choices, make the right choice

Hyundai Motor Group Announces AI Robotics Strategy to Lead Human-Centered Robotics Era at CES 2026

Hyundai Motor Group (the Group) today unveiled its transformative AI Robotics Strategy at the Consumer Electronics Show 2026 (CES 2026), presenting a bold roadmap for advancing human-robot collaboration under the theme ‘Partnering Human Progress’.

wenglor Presents AI Lab Cloud-Based High-Performance Platform for Creating AI Models

With uniVision 3, the modular standard software for wenglor machine vision devices such as the B60 series smart cameras and the MVC series machine vision controllers, images and height profiles can be evaluated easily and flexibly – without any programming knowledge.

Smart Inspections, Safe Processes

Testing and inspection procedures have always formed a core part of quality management. However, the framework conditions have changed significantly. Production processes are becoming more complex, new materials such as hydrogen-compatible metals are becoming more important, and digital technologies such as artificial intelligence (AI) and remote inspections are expanding the range of tools available to quality managers.

From Pen and Paper to AI: Transforming Manufacturing

As more supply chain risks like tariffs ripple through operations, outdated systems can no longer adapt to the pace of change required.

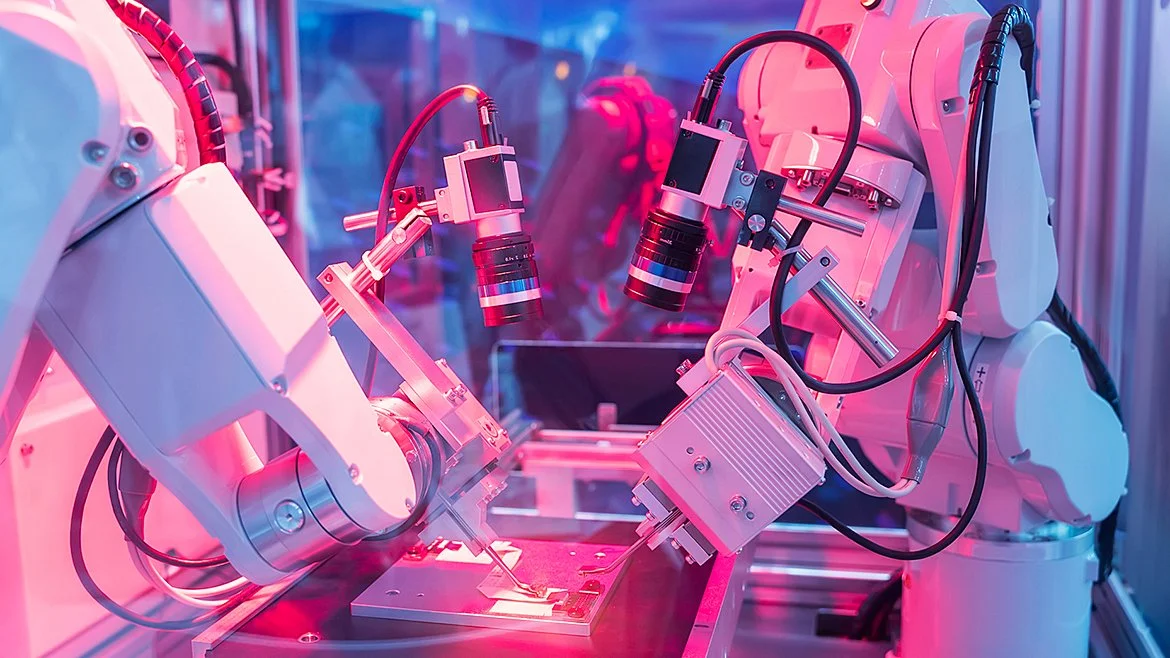

Navigating the Challenges of In-line AI Vision Systems

manufacturers are constantly seeking ways to improve production and product quality. This may involve increasing throughput and scrapping less material, or reducing machine downtime caused by the absence of an inline inspector. Often, their first step is investing in an automated inline machine vision system.

5 Powerful Ways AI Image Recognition Improves Quality Control in Manufacturing

Quality control in manufacturing is a crucial factor in the success of any industrial operation. It ensures that every product meets quality standards, satisfies customers, complies with regulations, and upholds a positive brand reputation. However, traditional quality control (QC) methods often face challenges such as inconsistency, low throughput, and high operational costs.

Machine Vision Gets Smarter

Machine vision systems are experiencing a significant transformation. Advances in artificial intelligence (AI), deep learning, and 3D imaging are improving inspection capabilities and making these systems more accessible. What once required extensive programming and vision expertise can now be accomplished through AI-powered systems.

The Future of Metrology: From Precision to Prediction

The future of metrology is rapidly changing. Instead of merely verifying quality, metrology is now poised to become an active, predictive force that drives continuous improvements throughout the manufacturing process. Today’s advancements in metrology are moving beyond simple measurement to become integral tools for smarter manufacturing systems.

University of Illinois Gains Cutting-Edge 3D Metrology Capabilities with EDMIS's Advanced 5-Axis MVi5 3D Metrology Center

The University of Illinois Grainger College of Engineering’s Mechanical Engineering Lab (MEL) has significantly enhanced its 3D metrology capabilities with the recent installation of an MVi5 3D Metrology Center from EDM INTELLIGENT SOLUTIONS (EDMIS). The MVi5 joins an existing RSH-SRX Robotic Metrology System from EDMIS that was installed at the lab in the spring of 2023.

AI in Quality Management: Hype vs. Reality

Artificial intelligence (AI) is dominating tech headlines across industries from retail to healthcare to financial services. In manufacturing, the excitement is just as strong.

ZEISS unveils AI-powered Research Data Platform; collaboration with Boehringer Ingelheim champions the future of personalized eye care

ZEISS demonstrates a new standard for the future of ophthalmic research at the Association for Research in Vision and Ophthalmology (ARVO) conference, from May 4 – 8, including the introduction of the new ZEISS Research Data Platform (ZEISS RDP), and a spotlight on the ongoing research collaboration with Boehringer Ingelheim to accelerate personalized, data-driven treatment approaches in ophthalmology.

The Death of Tactile Quality Control

Not long ago, quality assurance in aerospace was a narrow, hands-on process. Inspectors would physically verify installations: feeling the torque on bolts, tracing defects to their origin, and leaving behind ink-smudged paperwork as evidence of accountability. It was tactile, deliberate, and sometimes slower—but it worked.

The Next Frontier of Automation: Quality Assurance in an AI-Driven Era

The convergence of automation and quality is redefining how manufacturers detect defects, maintain standards, and continuously improve processes.

AI’s Double-Edged Sword: Security and Compliance in Manufacturing

More than half (55%) of organizations plan to adopt Generative AI for security this year, indicating a drastic increase in its use within sensitive business operations. Joining the surge in adoption is manufacturing, which is an industry adopting AI at a rapid pace. While AI undoubtedly creates an opportunity for greater efficiency, cost savings and precision, its rapid integration and orchestration exposes organizations to new security risks and regulatory challenges.

Next Generation Additive Manufacturing uses AI and Enhanced Laser Precision

Additive manufacturing (AM) and especially metal AM strives for increasing throughput and less scrap. Data preparation is key to increase productivity and shorten process development times.

AutoAlign Unveils "Visor", the AI Assistant Revolutionizing Industrial Operations, at Hannover Messe in Germany

AutoAlign, a leading partner of Nvidia, announces the launch of Visor, its cutting-edge AI assistant for industrial applications, unveiled today at Hannover Messe. Visor is designed to enhance operational efficiency, safety, and productivity across industries by providing hands-free, real-time assistance through workers’ safety glasses or mobile devices.

Embracing the Future: Key Trends Shaping Metrology

As industries continue to push boundaries in manufacturing and technology, metrology—the science of measurement—has become a cornerstone of innovation. The need for precision and efficiency has never been greater, and metrology is evolving to meet these demands.

How Generative AI Could Revolutionize Manufacturing Quality Functions

Within the manufacturing enterprise there is no more paper-intensive area than the quality function. The very nature of inspection and verification requires the evaluation of paperwork and the documentation of observed results.

AI in Manufacturing: Reshaping Quality Control and Efficiency

Every manufacturer knows the pain of unplanned downtime: the grinding halt of production, the scramble to identify the problem and the hours—or days—lost.

Customers Favor AI-Based Technologies but Automakers May Not Have Best Advanced Tech Strategy, J.D. Power Finds

Are vehicle owners becoming overwhelmed with technology features that don’t solve a problem, don’t work, are difficult to use or are just too limited in functionality?