Five Ways Advanced Imaging is Improving Quality

The importance of modern quality control

Manufacturers today face growing pressure to deliver safe, high-quality products at faster speeds and higher volumes. Manual inspection just can’t keep up - with its limits in speed, accuracy, and consistency. That’s why advanced imaging technologies are becoming essential on the modern production line.

From catching defects you can’t see with the naked eye to checking seals, labels, and foreign materials, cameras like 3D, thermal, and hyperspectral - powered by intelligent software - are taking quality control to a whole new level.

Advanced machine vision - especially when powered by a robust software platform - provides a solution that meets these demands. By integrating 3D, thermal, and hyperspectral cameras with intelligent software, manufacturers can elevate quality control to new levels of precision.

Let’s explore five key ways these technologies are improving food quality control.

1. Comprehensive defect detection: surface to subsurface

Advanced imaging systems allow manufacturers to identify both visible and hidden product defects.

3D vision is employed to capture the shape, height, and volume of items, which helps in identifying cracks, dents, and surface irregularities.

Hyperspectral imaging goes beyond what the human eye or 2D cameras can detect, capturing rich spectral data that reveals chemical signatures, allowing for the detection of internal bruising or spoilage, e.g. damaged apples or foreign parts in coffee and many more.

A single software platform can be used to apply inspection rules and defect criteria across different sensor types, ensuring consistent and comprehensive detection at production speed.

2. Ensuring packaging integrity and seal verification

Faulty seals or improperly filled containers can lead to contamination, spoilage, and costly recalls. Thermal imaging plays a key role here:

Thermal cameras detect heat patterns to verify whether packaging seals are complete and uniform.

3D and 2D vision systems validate fill levels, correct closure of caps or lids, and overall packaging consistency.

By integrating data from multiple camera types into one inspection process, manufacturers can ensure that each unit meets safety and integrity requirements before it leaves the line.

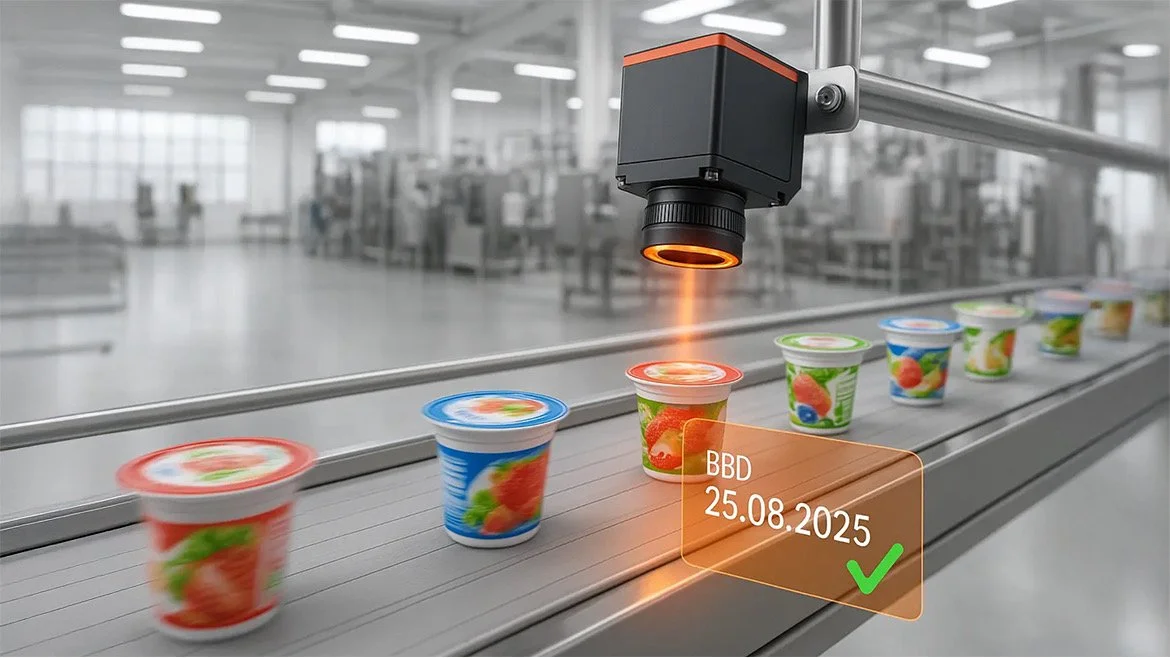

3. Accurate reading and verification of labels and expiry dates

Legible and accurate labelling is crucial for traceability and regulatory compliance. High-resolution cameras combined with intelligent software tools ensure accuracy:

2D cameras equipped with OCR (Optical Character Recognition) and OCV (Optical Character Verification) verify printed text like “Best Before” dates, batch numbers, and allergen information and many more.

AI-enhanced vision tools compensate for variations in font, lighting, and print quality, ensuring robust identification.

This prevents mislabelled or expired products from reaching consumers, protecting both brand reputation and consumer safety.

4. Foreign material detection

Contaminants such as plastic, wood, or other foreign objects in food products pose serious safety risks. While traditional metal detectors are effective for metallic contaminants, advanced imaging brings new capabilities:

Hyperspectral imaging can detect a wide range of non-metallic contaminants based on their unique spectral signatures.

Thermal imaging may also highlight foreign objects with different heat retention characteristics, particularly during heated or cooled processing steps.

These imaging methods help detect what traditional sensors may miss, providing a more complete safety net.

5. Automated sorting and grading for product optimization

Intelligent vision systems enable consistent sorting and grading based on multiple attributes:

3D imaging assists in sorting by size and volume.

Color cameras ensure visual consistency and identify blemishes or discoloration.

Hyperspectral imaging evaluates internal ripeness, sugar content, or moisture levels.

By combining these data sources and applying rule-based logic or AI-driven models, food processors can automate complex grading tasks, reduce waste, and enhance product value.

The role of software in enabling advanced imaging

Camera hardware generates large volumes of raw data—3D point clouds, thermal maps, hyperspectral cubes so called hypercubes—but it’s the software that extracts actionable insights.

A powerful, flexible vision software platform enables this by offering:

Multi-sensor compatibility: Integrates 1D, 2D, 3D, Thermal, and Hyperspectral cameras using standard interfaces like GigE, USB, and CoaXPress.

Graphical programming environments: Drag-and-drop tools allow users to design inspection workflows without coding expertise.

Comprehensive processing libraries: Includes tools for measurement, color analysis, defect classification, OCR, and more.

AI and deep learning: Enhances robustness and adaptability, especially for natural products with high variability e.g. tomatoes.

Hardware-agnostic deployment: Runs on PCs or embedded devices, offering flexibility for centralized or edge-based setups.

This software-centric approach transforms imaging hardware into intelligent inspection systems that can evolve with changing production needs.

Looking ahead: The future of imaging in quality control

As imaging sensors become more compact and affordable, their use in food production will only grow. Key trends include:

Sensor fusion: Real-time integration of multiple imaging modalities (e.g., 3D + thermal + Hyperspectral imaging) for a comprehensive product view.

Edge computing: On-device processing enables faster decision-making and reduces network latency.

AI-powered adaptation: Self-learning systems that improve accuracy and adapt to production variations.

These advances align with the goals of Industry 4.0 - creating intelligent, connected systems that enhance productivity and product safety.

A smarter, safer world through vision technology

Advanced imaging - when combined with intelligent software - offers measurable benefits for quality control. From defect detection and foreign body identification to label verification and automated sorting, these technologies are transforming how the food industry ensures safety, efficiency, and product consistency.

Even to ensure that the transportation wrap around the products doesn’t have any damage is a classic task for image processing and ensures that the customer can carry the product undamaged.

With platforms enabling seamless integration of diverse sensors and analytics, the path forward is clear: smarter, faster, and more reliable food inspection at every stage of production.