You have choices, make the right choice

Optimizing Manufacturing and Quality Synergy: Advanced Model-Based Enterprise Strategies for Bidirectional Data Exchange

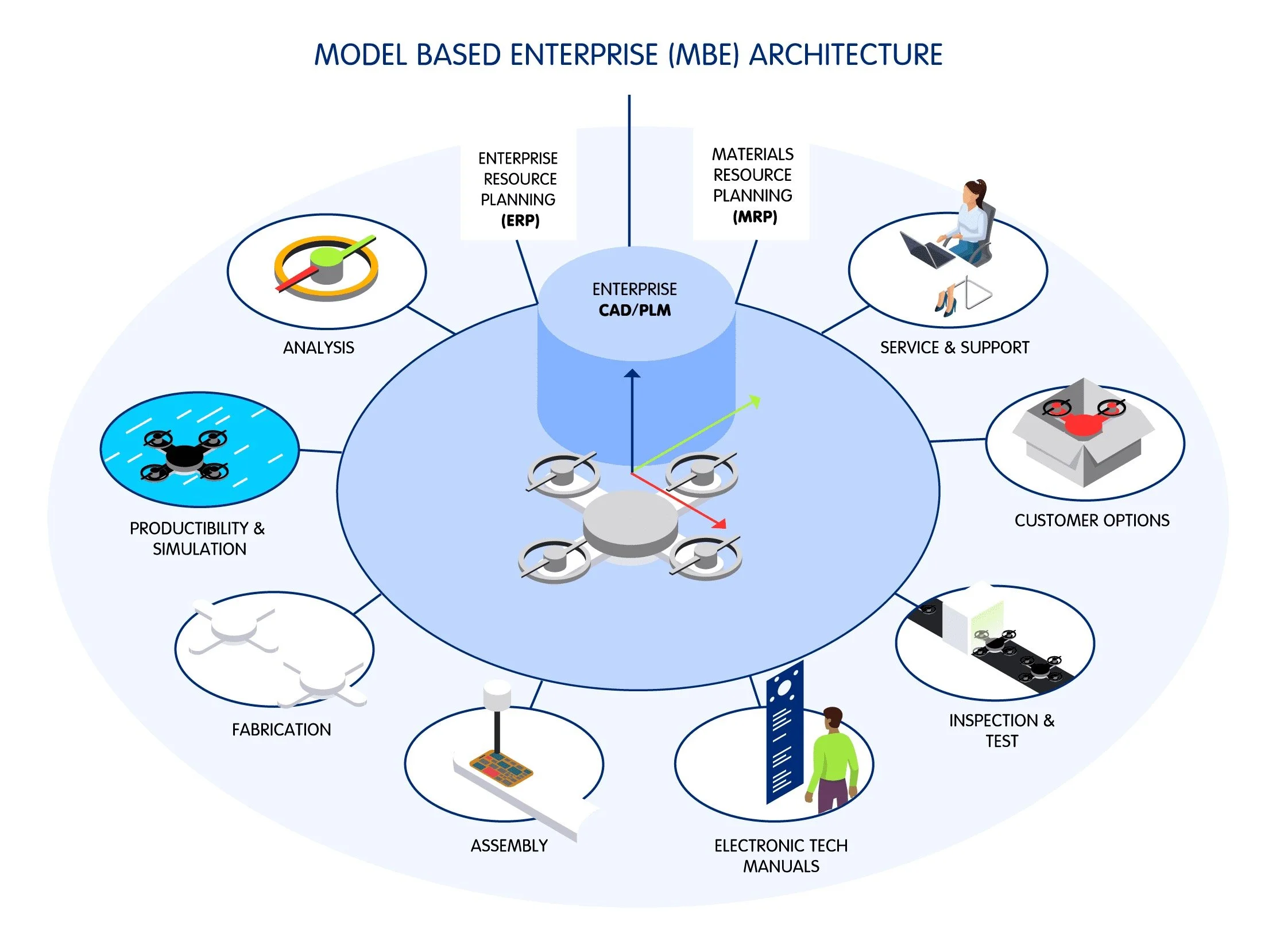

Model-Based Enterprise (MBE) has emerged as a pivotal paradigm shift, replacing traditional paper-based processes with fully digital, model-centric approaches. This transformation is driven by the need for greater efficiency, accuracy, and collaboration across the product lifecycle.

3 Project Planning Recommendations to Ensure QMS Development Success

Looking to improve the efficiency of inspection management, CAPA management, and other quality control processes, companies across industries are increasingly investing in implementing quality management systems.

Kaizen Explained in Detail

Kaizen (改善) = Kai (change) + Zen (good) → Change for the better

or more commonly translated as Continual Improvement.

It is both a philosophy and a practical method.

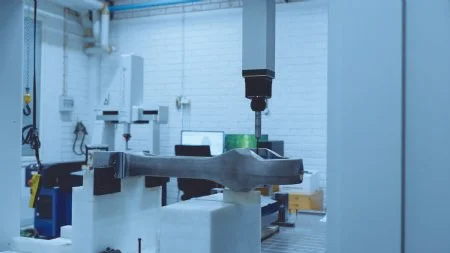

Mastering CMM Correlation: A Guide to Validating Upgrades and Avoiding Costly Mistakes

In the ever-evolving field of dimensional metrology, integrating cutting-edge measurement technologies into established quality assurance workflows presents a formidable challenge.

New Benchmarks in Quality Inspection and Data Analysis

ZEISS Industrial Quality Solutions (ZEISS IQS) announces the latest software updates for ZEISS INSPECT and ZEISS PiWeb, addressing the growing challenges of industrial quality control. By providing holistic solutions ZEISS IQS enables end-to-end inspection processes and streamlined workflows.

Quality at Purso-Tools ensured by Mitutoyo

Purso-Tools Oy, located in Pori on the west coast of Finland, is a manufacturer of heavy-duty camshafts and connecting rods for customers that include manufacturers of engines for ships and power plants. Indeed, the company is the world’s largest producer of camshafts for heavy industry and, in its sector, one of the few of its kind — especially in Europe — manufacturing camshafts for nearly all major large engine manufacturers. Its well-known customers include Wärtsilä, MAN, Bergen Engines (Rolls-Royce), Bosch, and Caterpillar.

From Pen and Paper to AI: Transforming Manufacturing

As more supply chain risks like tariffs ripple through operations, outdated systems can no longer adapt to the pace of change required.

ZEISS Opens New Connecticut Quality Excellence Center to Strengthen Northeast Manufacturing

ZEISS Industrial Quality Solutionstoday announced its new Quality Excellence Center in Bloomfield, Connecticut, as part of its continuous expansion of support for U.S. manufacturers. Located at 340 West Newberry Rd., the facility will provide advanced resources for precision metrology, technology demonstrations, and local experts who specialize in helping manufacturers solve industry challenges with innovative solutions.

PRECISION IN MOTION: A SUCCESSFUL SHOWCASE AT THE MOTION+POWER TECHNOLOGY EXPO

At the center of our showcase was the introduction of extended GT tailstock configurations — engineered to deliver greater range, stability, and precision for complex gear inspection applications.

These new tailstock options extend measurement flexibility, allowing operators to handle a wider variety of workpiece lengths and diameters while maintaining sub-micron accuracy. Designed for compatibility across our GT series gear inspection systems, they enable faster setup times, improved repeatability, and enhanced support for high-torque applications.

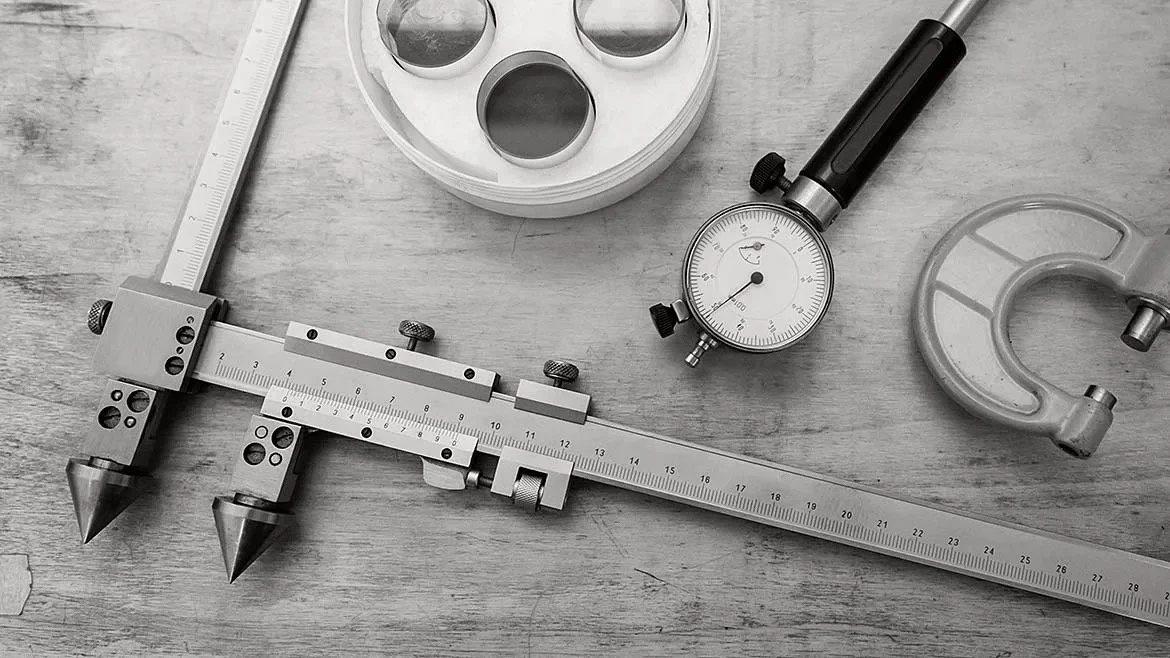

Making Sense of Gage R&R Analysis

The term Measurement Systems Analysis (MSA) refers to a collection of experimental and statistical methods designed to evaluate the error introduced by a measurement system, and the resulting usefulness of that system for a particular application. In manufacturing, measurement system quality directly affects decisions about processes, products, and a manufacturer’s ability to meet their customers’ requirements.

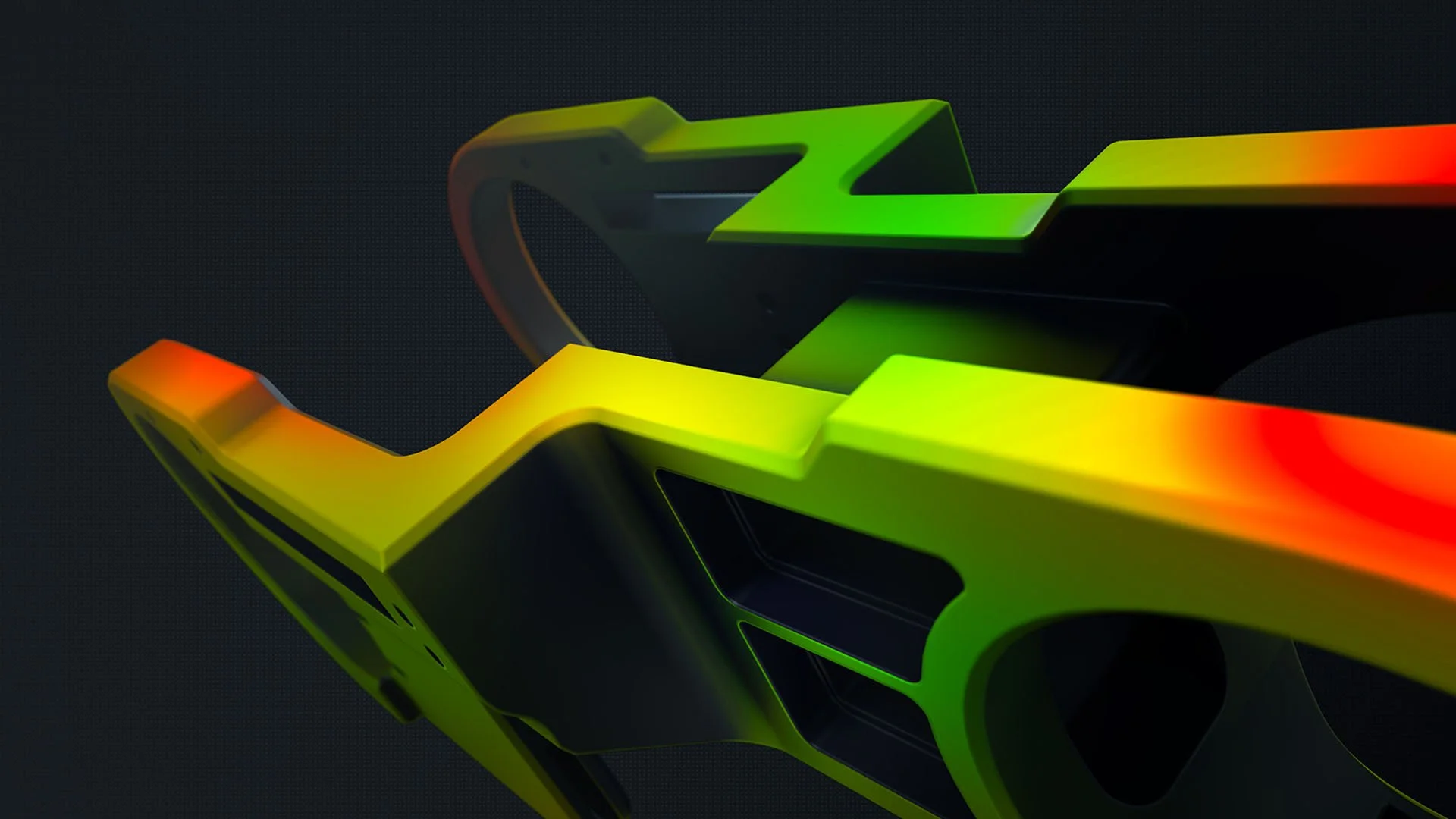

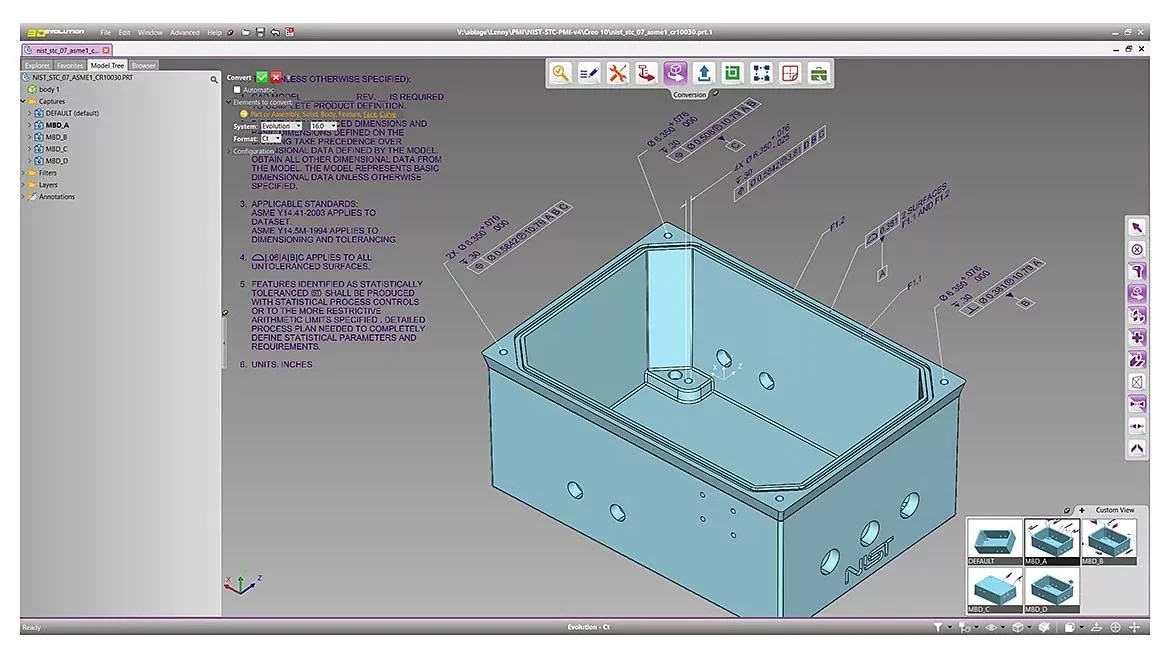

Model-Based Definition in 3D CAD: Advances, Methods and Quality Implications

For much of the industrial era, engineering communication revolved around 2D technical drawings. Today, advances in Model-Based Definition (MBD) are reshaping that paradigm.

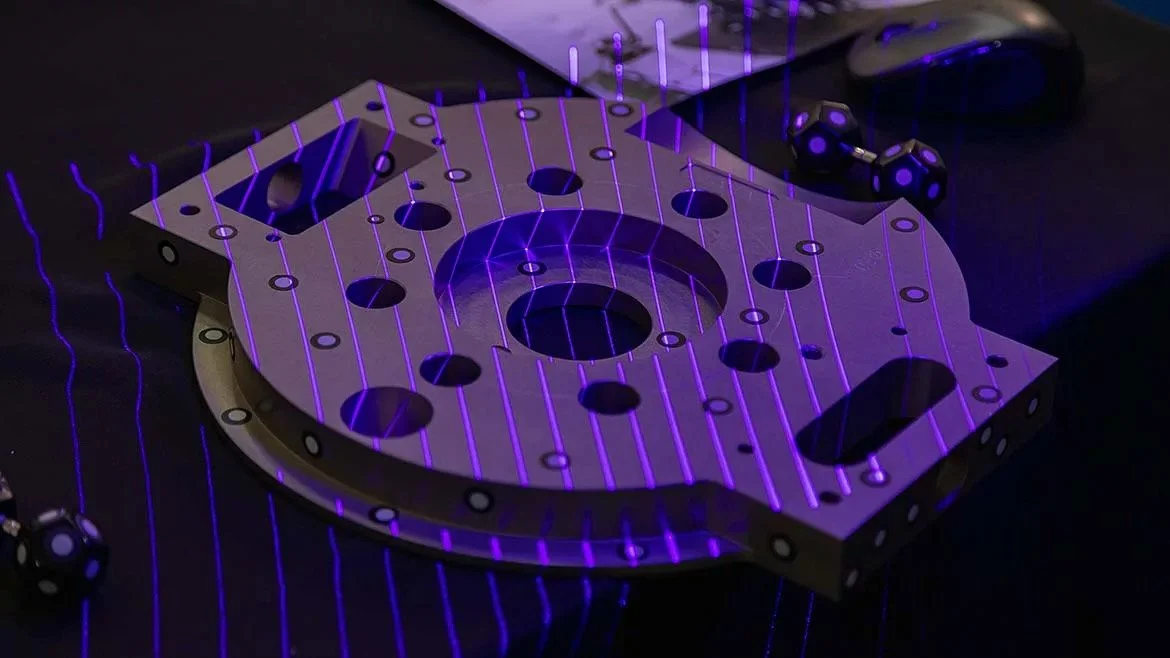

Quality, Manufacturing, and Metrology: The Backbone of Modern Industry

In today’s fast-paced global economy, where supply chains stretch across continents and technology advances at lightning speed, three essential pillars hold up industrial success: quality, manufacturing, and metrology.

When All You Have Is a Hammer: Key Considerations When Evaluating Appropriate Tools for Quality Inspections

It is vitally important that quality inspectors maintain a clear understanding of what tools are available and appropriate for any feature inspection. Most features of size could be measured with any of a half dozen different tools. Deciding which tools to use and, more importantly, which tools not to use is essential to ensuring the accuracy, repeatability, and establishing confidence in your report.

Shift Focus: Quality Professionals Need to Shift Focus to Short-term Results

Learn how quality professionals can shift from long-range plans to short-term results. Get visible wins, measurable milestones, and keep stakeholders engaged by breaking down large projects into smaller, impactful steps.

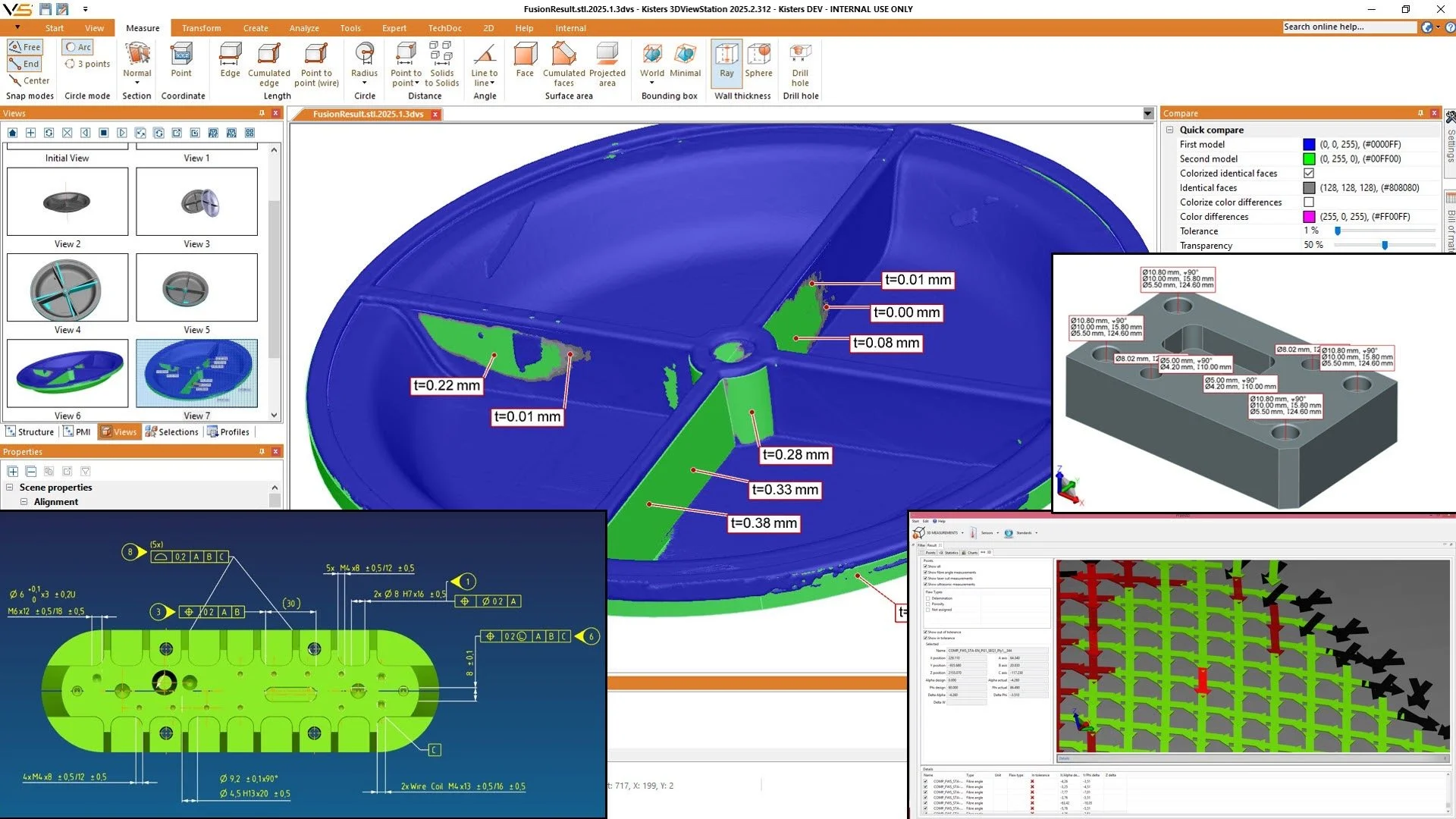

Quality made visible thanks to powerful 3DViewStation graphics

In modern manufacturing, quality is no accident – it is the result of precise planning, comprehensive documentation, and efficient tools. Kisters 3DViewStation provides companies with a powerful visualization and analysis tool that has established itself as an indispensable component in the quality assurance of 3D CAD data. From goods receipt to prototyping to series production approval, the software enables fast, precise, and system-independent inspection of complex CAD models.

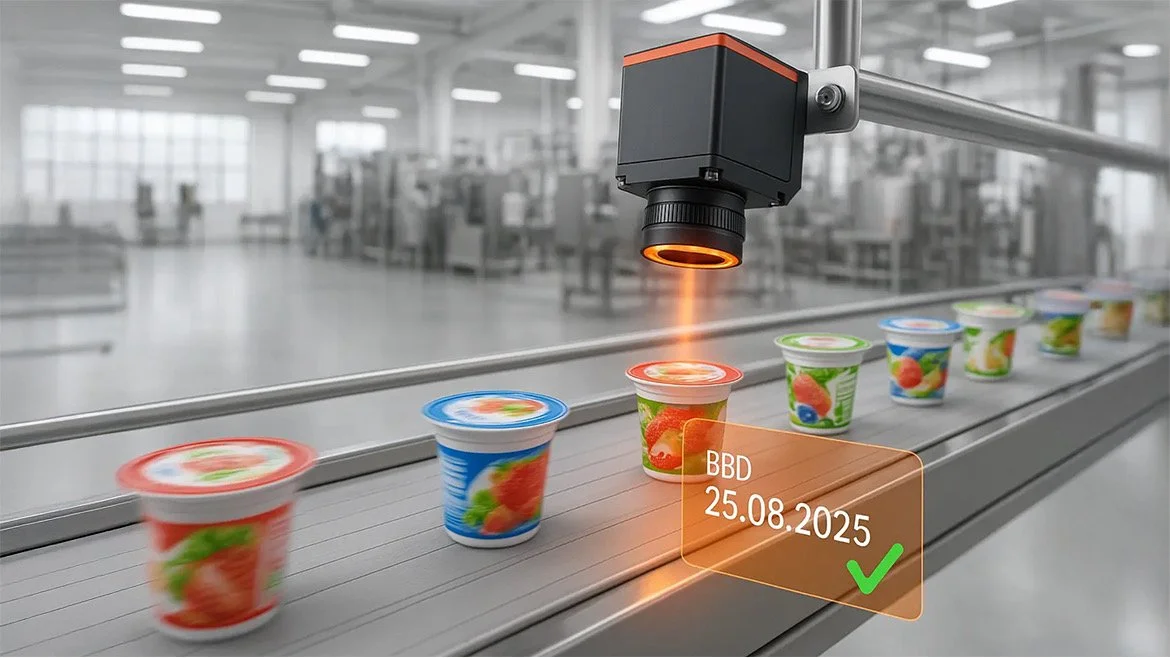

Five Ways Advanced Imaging is Improving Quality

Manufacturers today face growing pressure to deliver safe, high-quality products at faster speeds and higher volumes. Manual inspection just can’t keep up - with its limits in speed, accuracy, and consistency. That’s why advanced imaging technologies are becoming essential on the modern production line.

Beyond Inspections: The Secret to Building a Quality-Driven Manufacturing Culture

Quality isn’t a department. It’s a mindset. That mindset can mean the difference between thriving and simply surviving. The modern customer demands flawless products, delivered on time, every time. Yet for many manufacturers, quality still feels like an endless game of catch-up – reacting to problems after they happen, throwing resources at rework and trying to patch cracks in the process while the production line keeps moving.

Rethinking Quality: Why Additive Manufacturing Must Grow Up to Move Forward

For years, additive manufacturing (AM) has been synonymous with prototyping. Fast, flexible, and relatively affordable, it allowed engineers and designers to bring ideas to life quickly. Expectations around the technology set are continuing to grow as AM processes edge further and further into the realm of production.

Beyond the Factory Floor: Why Smarter Tools Mean Smarter Quality Control for U.S. Manufacturers

How new tools—including 3D laser scanning and probing devices—can help the industry innovate and adapt in an increasingly competitive (and tariffed) world.

AMETEK to Acquire FARO Technologies

AMETEK, Inc. (NYSE: AME) and FARO Technologies, Inc. (Nasdaq: FARO) today announced that they have entered into a definitive agreement under which AMETEK will acquire all outstanding shares of FARO Technologies common stock for $44 per share in cash, which represents an approximate 40% premium to FARO’s closing price on May 5, 2025. The transaction values FARO at an enterprise value of approximately $920 million. The boards of directors of both companies have unanimously approved the transaction.