THE IMPACT OF 3D SCANNERS ON NASCAR STOCK CAR RACING

Reaume Brothers Racing is an American professional stock car racing team that competes full-time in the NASCAR Craftsman Truck Series. Owned by Josh Reaume, the team fields the No. 22 Ford F-150 full-time for multiple drivers, the No. 27 part-time for Keith McGee, and the No. 33 full-time for Lawless Alan.

3D Design and Maintenance on Racing Vehicle with Scantech 3D Scanner

A France 3D Scanning company, BTRD3D, helped LR Motor Company in France to scan the tubular chassis of a race vehicle using the 3D scanner KSCAN 20. The CAD model generated from the scanned data served as a basis for the development of a new product, which means helping the company to conceive a new high-performance buggy for competition.

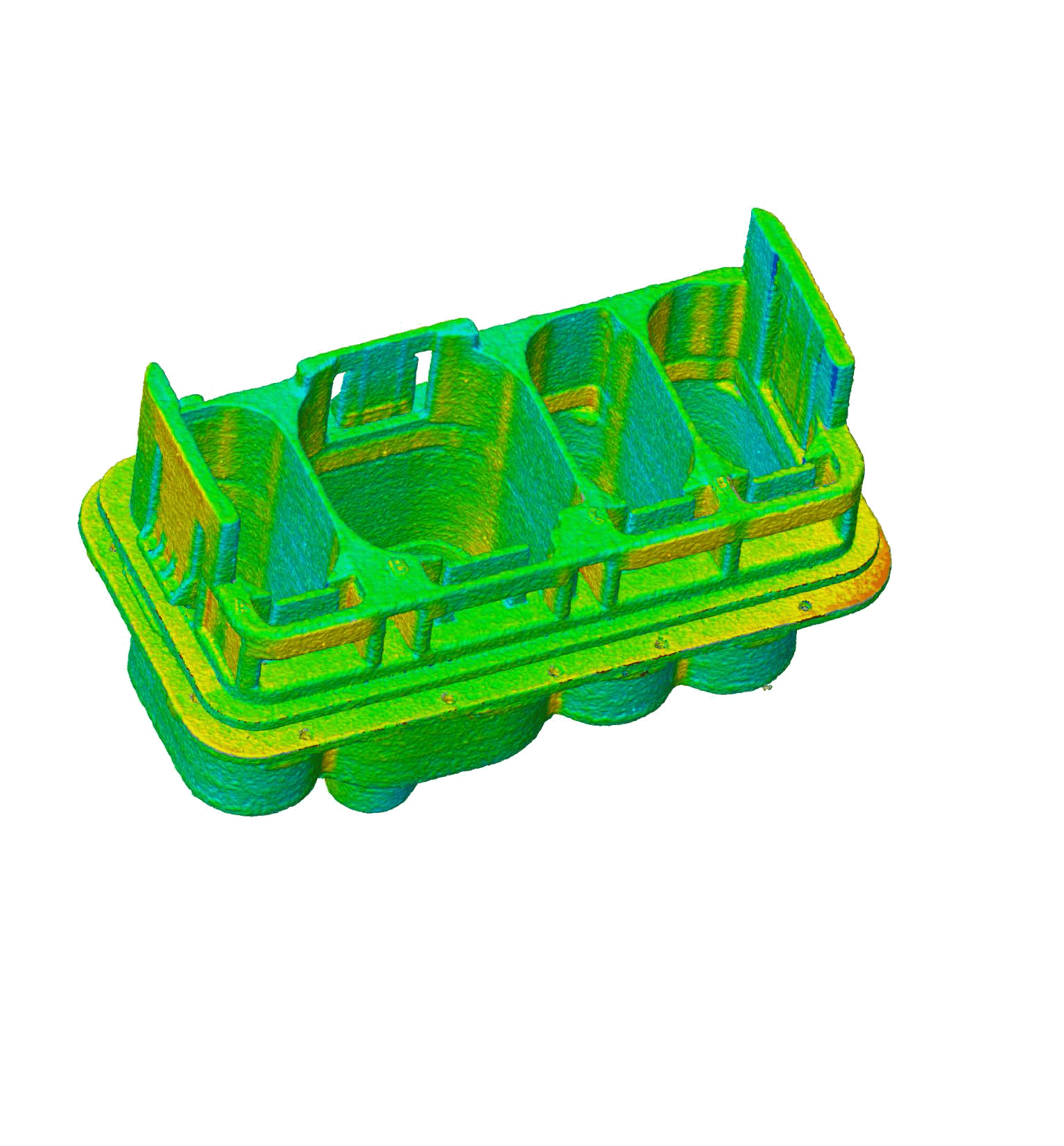

What are the effectiveness and gains of 3D point cloud inspection?

Point cloud technology refers to the use of a set of data points in a 3D coordinate system, which is commonly defined by X, Y and Z axes. From a metrological standpoint, the actual points in a point cloud represent those X, Y and Z geometric coordinates for each single point.

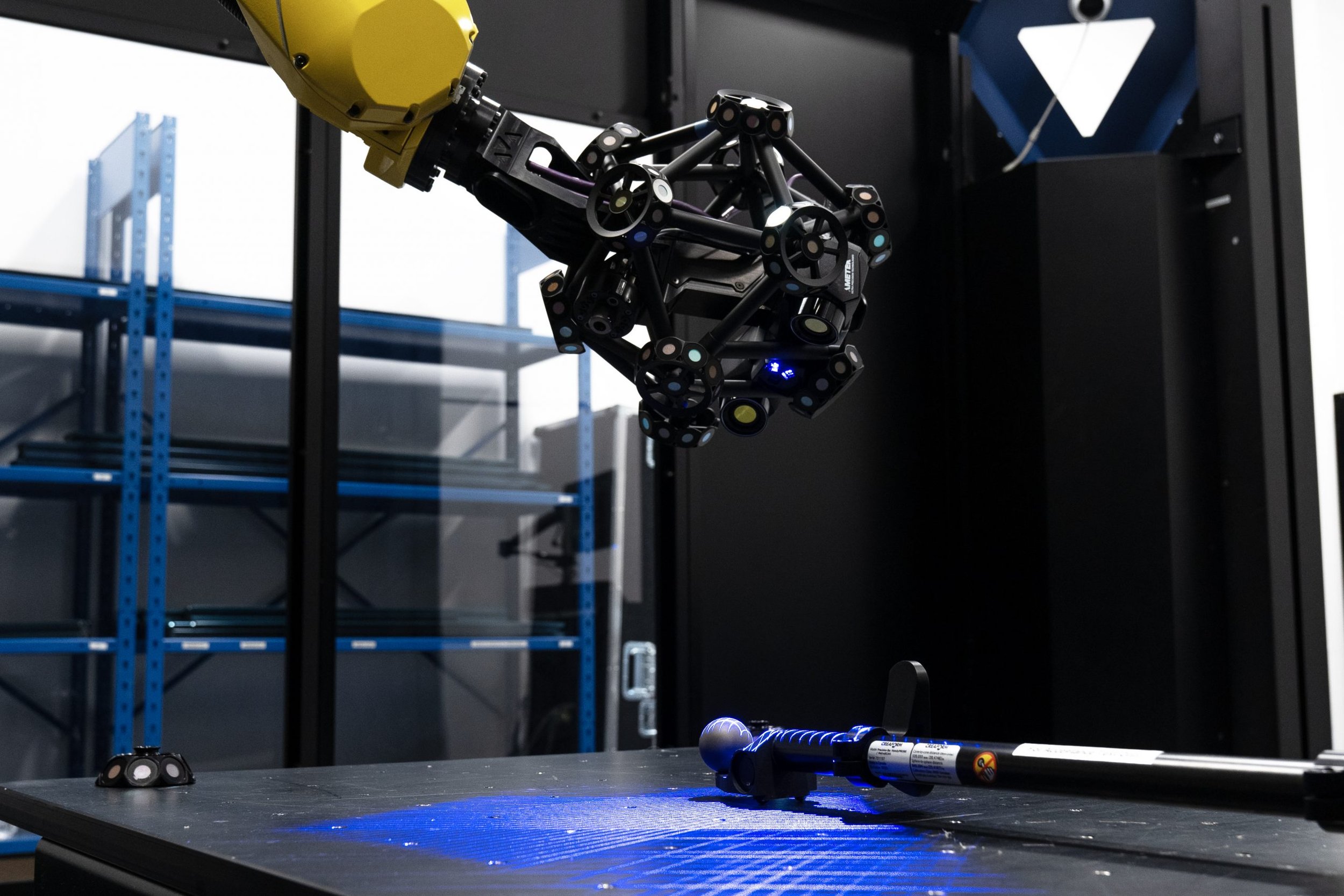

Should a CMM be replaced with a robot?

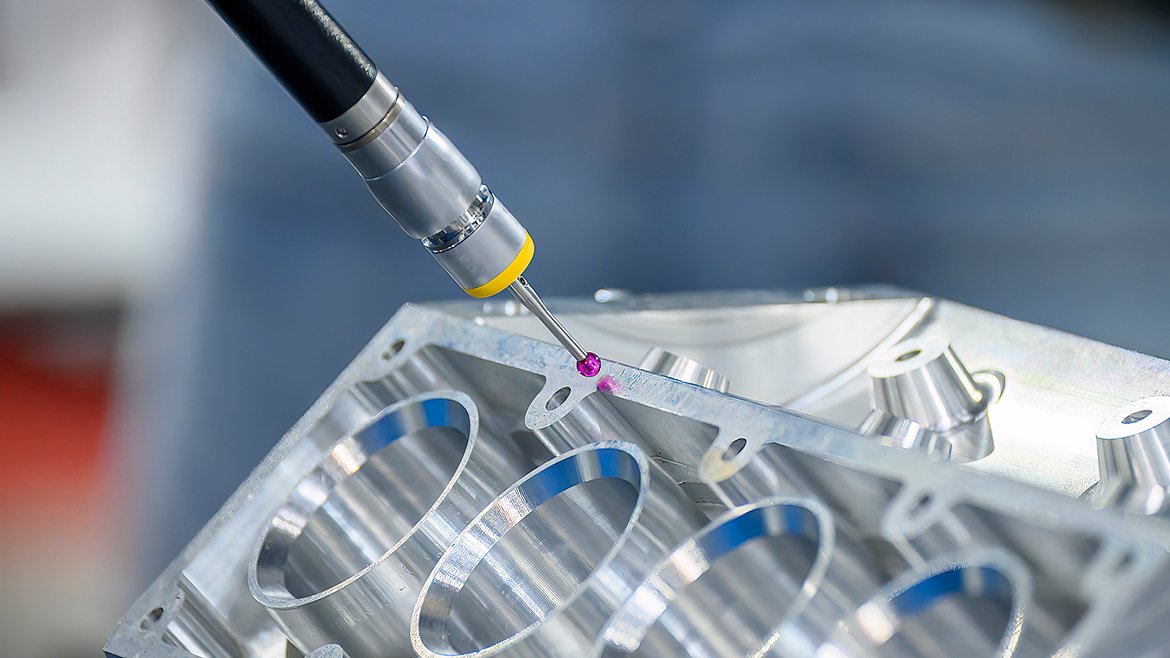

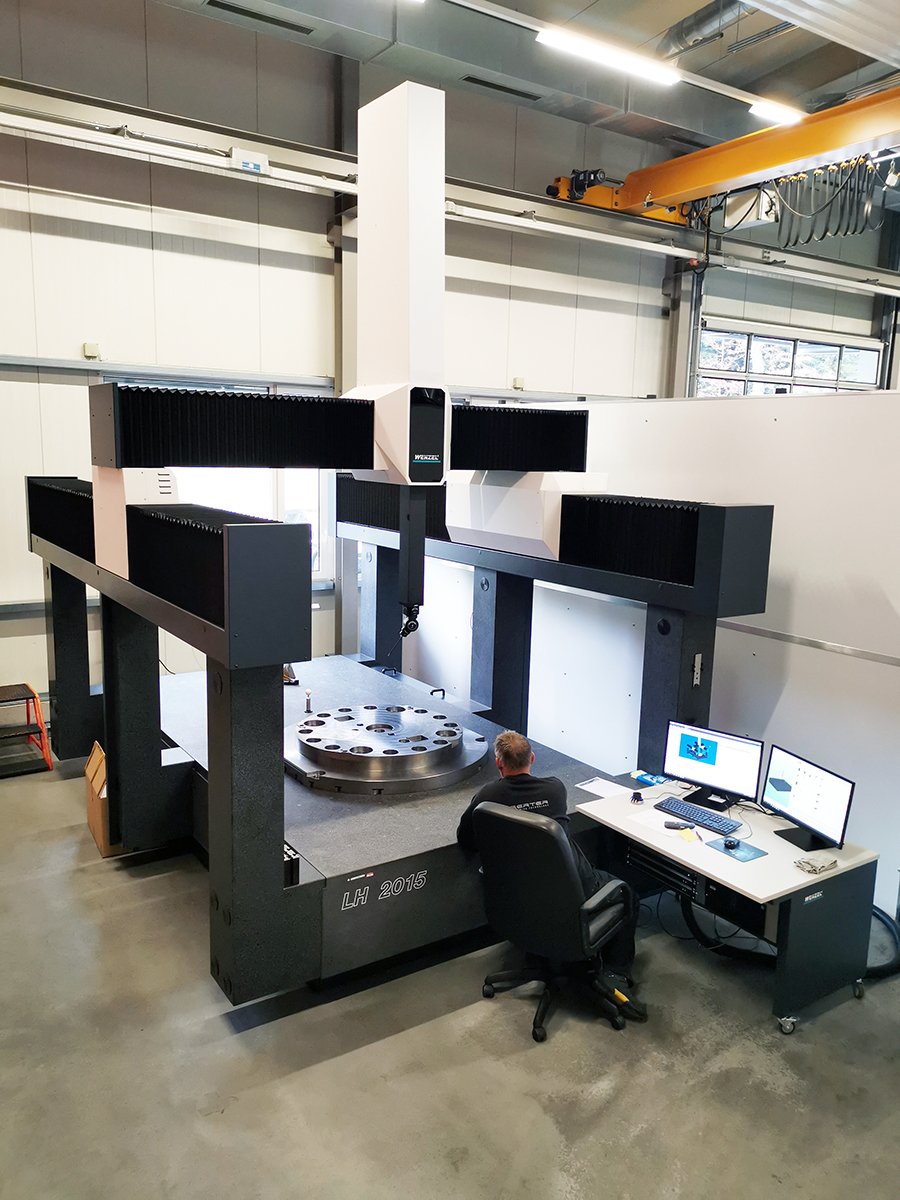

Deciding whether to replace a Coordinate Measuring Machine (CMM) with a robotic measurement system can be challenging. To make an informed choice, it’s essential to understand the unique strengths and limitations of each technology. Let’s explore this in more detail, with examples to help you visualize the differences.

INNOVATIVE 3D SCANNER SERVING THE LARGEST INDUSTRIAL PARTS A CREAFORM’S CLIENT SUCCESS STORY FEATURING SIEMENS ENERGY

With over 90,000 employees worldwide, Siemens Energy is a global company operating in various sectors of the energy industry, including grid technologies, decarbonization of industries, wind energy, and conventional power generation.

Unlocking the Future of Coordinate Measuring Machines (CMM): Advanced Controllers and Industry Evolution

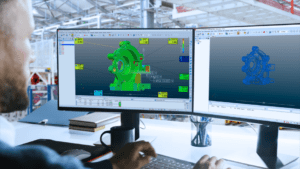

In the world of precision manufacturing, coordinate measuring machines (CMMs) stand as pillars of quality control and assurance. These sophisticated devices have become indispensable tools for verifying the dimensions of manufactured parts with incredible accuracy. At the heart of every CMM lies its controller - the brain that coordinates movements, processes data, and interfaces with measurement software. As manufacturing tolerances tighten and the demand for faster, more accurate measurements grows, CMM controllers have become a focal point for technological advancement in the metrology industry.

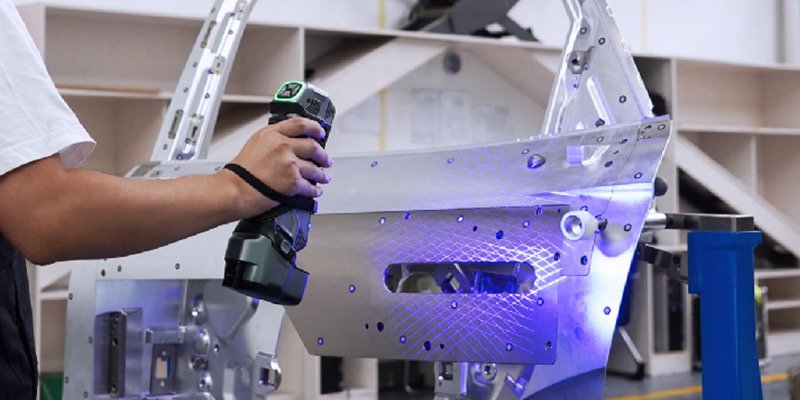

UNVEILING THE HIDDEN HURDLES OF AUTOMOTIVE PART MANUFACTURERS

Manufacturing sheet metal is far from a simple task. It requires rigorous inspection, primarily due to the high quality and stringent safety standards required in the automotive industry. No doubt, a combination of advanced technology and skilled labor must be involved to ensure that the sheet metal components are cut and shaped to precise dimensions. This includes checking for correct length, width, surface profile, and overall shape. Quality inspection is vital because automotive sheet metal must withstand stress and fatigue over the vehicle’s lifetime.

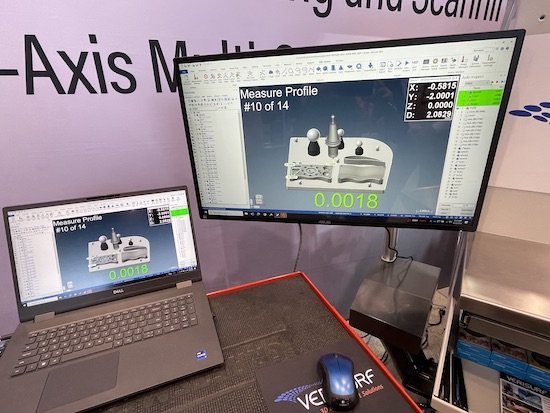

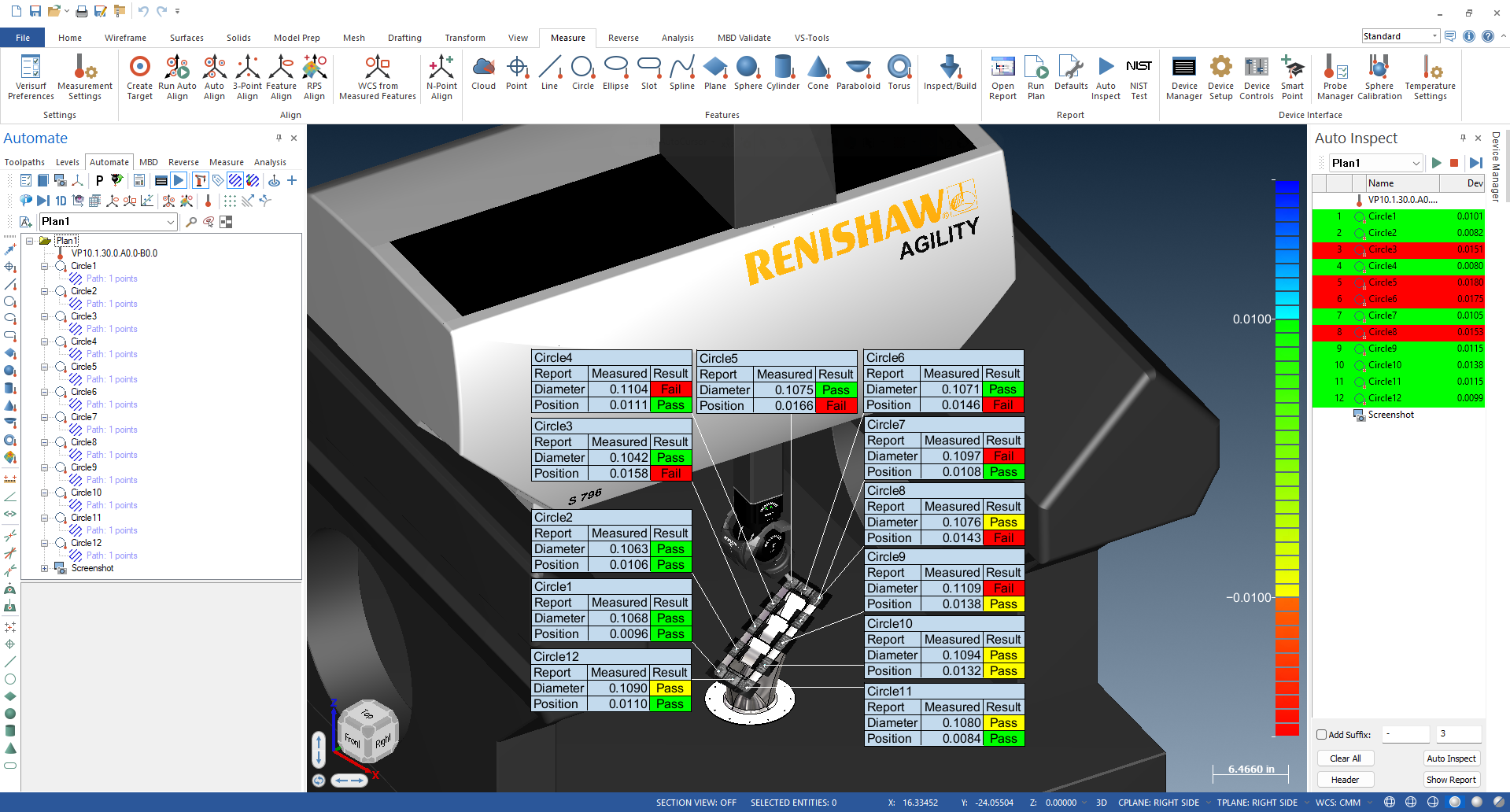

In-Process Inspection Integrated with Machine Tools

CAD/CAM-based metrology software provider Verisurf Software has released its Machine Tool Probing (MTP) suite, which supports in-process part inspection directly on machine tools.

Integrated Metrology: The Next Frontier in Manufacturing

Imagine a manufacturing cell where robots and machines work in concert, assembling complex products with precision.

THE DIFFERENCE BETWEEN STATED ACCURACY AND ACCREDITED ACCURACY

How to Interpret the Accuracy of Measuring Instruments?

Stated accuracy refers to the accuracy that a manufacturer claims its measuring devices have, while accredited accuracy is an objective measurement of that product’s true accuracy.

New Status Metrology website targets enhanced user experience

Status Metrology has announced the launch of its newly redesigned website.

MORE PRECISE INNOVATION WITH COMPUTED TOMOGRAPHY

WENZEL’s Computed Tomography range, the exaCT series, is exactly accurate. It assists in completing projects faster by providing critical information more quickly.

CREAFORM ON BOARD TO HELP AMERICAN MAGIC WIN THE 37TH AMERICA’S CUP

At the end of August 2024, the New York Yacht Club’s American Magic set sail from Barcelona in its bid to win the Louis Vuitton 37th America’s Cup. According to organizers,

New Hexagon quality inspection innovation combines laser tracking and non-contact measurement, slashing large-scale manufacturing processes from hours to minutes

The new Leica Absolute Tracker ATS800 delivers accurate measurement of key features from a distance, using direct scanning to meet the demands of low-tolerance inspection and alignment in aerospace and other large-scale manufacturing sectors.

ZEISS Leads IMTS Visitors on a Journey to Discover Their Superforce

ZEISS Industrial Quality Solutions is presenting a hero's journey at the 2024 International Manufacturing Technology Show (IMTS) booth #134302 in the East Hall, Level 3. This interactive experience allows visitors to learn about the ZEISS superforce of precision quality technologies and software and its team of experts. Throughout their journey, visitors will answer quick questions and gain insight into technologies that support quality across the entire product lifecycle while winning prizes.

Verisurf 2025 Software Now Available

CAD/CAM Based Metrology Platform Expands 5-Axis Sensor Support and Adds New Features Across Application Suites

Hexagon Launches VISIUS: Affordable High-Speed Measurement for Machine Shops

At the International Manufacturing Technology Show in Chicago, Sept. 9–14, Hexagon’s Manufacturing Intelligence division launches VISIUS, an intuitive optical coordinate measuring solution designed to address the evolving needs of modern manufacturers.

Intelligent, Wireless and Palm-Sized 3D Scanner SIMSCAN-E

The SIMSCAN-E is an intelligent, wireless, palm-sized 3D scanner that blends lightweight design with top-tier performance. With advanced wireless scanning technology, it sets a new standard for portable and wireless 3D scanning.

The SIMSCAN-E offers significant benefits by leveraging advanced edge computing and high-definition industrial cameras to deliver exceptional precision and efficiency in capturing 3D data. With the ability to measure up to 6.3 million points per second,it is deal for industries that demand high-performance scanning solutions.