Unlocking the Future of Coordinate Measuring Machines (CMM): Advanced Controllers and Industry Evolution

The move towards more open and interoperable CMM systems is gaining momentum

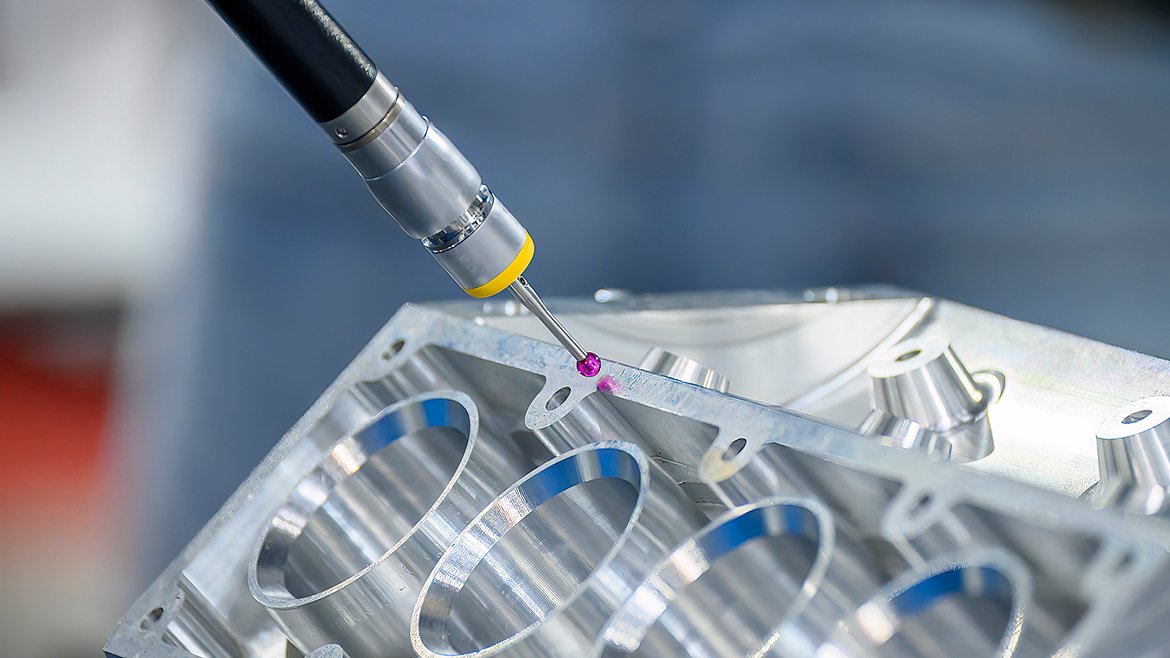

In the world of precision manufacturing, coordinate measuring machines (CMMs) stand as pillars of quality control and assurance. These sophisticated devices have become indispensable tools for verifying the dimensions of manufactured parts with incredible accuracy. At the heart of every CMM lies its controller - the brain that coordinates movements, processes data, and interfaces with measurement software. As manufacturing tolerances tighten and the demand for faster, more accurate measurements grows, CMM controllers have become a focal point for technological advancement in the metrology industry.

The Evolution of CMM Controllers: Past Challenges and Limitations

Traditionally, CMM controllers were purpose-built for specific machines and software ecosystems. Early controllers were often limited in their processing power, communication capabilities, and flexibility. They were designed to work within closed systems, where the CMM hardware, controller, and software were all supplied by a single manufacturer. This approach, while ensuring compatibility, often resulted in systems that were difficult to upgrade or adapt to changing needs.

The 'Locked Garden' Problem in the CMM Industry

CMM Software Then and Now: How to Measure Parts Faster

InnovMetric's Marc Soucyexplains how CMM software can help you measure parts quickly and accurately, how to use these techniques most effectively, and how automating can help.

The CMM industry has long operated as a “locked garden,” where machines, software, and controllers are exclusively supplied by a single vendor. This closed ecosystem approach has created significant challenges for users:

Limited Flexibility: Users are often locked into a single vendor’s ecosystem, making it difficult to integrate new technologies or software from other providers.

Costly Upgrades: Upgrading or retrofitting existing CMMs often requires replacing entire systems, leading to substantial costs and downtime.

Reduced Innovation: The closed nature of these systems can stifle innovation by limiting competition and the integration of new technologies.

Obsolescence Risks: As technology advances, older systems may become obsolete, forcing companies to make significant investments in entirely new setups.

This “locked garden” approach has long been a pain point for CMM users, driving a need for more open and flexible solutions in the industry.

Emerging Trends in CMM Controller Technology

In response to these challenges, the CMM industry is witnessing a shift towards more open and versatile controller solutions. Key trends include:

Universal Compatibility: New controller designs aim to work with a wide range of CMM brands and models, breaking down the barriers of proprietary systems.

Software Agnosticism: Advanced controllers are being developed to communicate natively with various CMM software packages, eliminating the need for complex protocol adaptations.

Plug-and-Play Functionality: The industry is moving towards controllers that can be easily retrofitted to existing CMMs without extensive hardware modifications or rewiring.

Enhanced Performance: Modern controllers offer significantly improved processing power, enabling faster scanning speeds and higher sampling rates.

Future-Proofing: New controller designs are built with the flexibility to support both current and future sensor technologies.

Plug-and-Play Retrofit Solutions: A New Approach to CMM Upgrades

One of the most significant developments in CMM controller technology is the emergence of plug-and-play retrofit solutions. These advanced controllers are designed to seamlessly replace existing controllers on a wide range of CMM brands and models. The key advantages of this approach include:

Minimal Downtime: Retrofits can often be completed in a matter of days, rather than weeks or months required for full system replacements.

Cost-Effectiveness: By upgrading just the controller, companies can significantly enhance their CMM’s capabilities at a fraction of the cost of a new machine.

Preserving Existing Investments: Retrofit solutions allow companies to leverage their existing CMM hardware and software, protecting previous investments.

Simplified Integration: These controllers are designed to work with existing error maps and calibration data, minimizing the need for extensive recalibration.

Backplate of an advanced plug and play controller - compatible with the original cabling of the machine Source: EasyCMM

Key Features of Modern CMM Controllers

As CMM controller technology advances, several key features are emerging as standard in high-performance systems:

High-Speed Processing: Modern controllers offer significantly faster processing speeds, enabling quicker measurements and data analysis.

Enhanced Sampling Rates: Advanced controllers can handle much higher sampling rates, allowing for more detailed and accurate measurements, especially in scanning applications.

Multi-Sensor Support: New controllers are designed to work with a wide range of sensors, including touch-trigger probes, scanning probes, and optical sensors.

Advanced Motion Control: Improved algorithms for motion control result in smoother movements and more accurate positioning.

Temperature Compensation: Built-in support for multiple temperature sensors allows for real-time compensation of thermal effects on measurements.

Flexible Communication: Ethernet connectivity and support for various communication protocols enable easier integration with factory networks and data systems.

The Impact of Advanced Controllers on CMM Performance and Capabilities

The adoption of advanced controllers can have a transformative effect on CMM performance:

Increased Productivity: Faster processing and higher scanning speeds can significantly reduce measurement cycle times.

Improved Accuracy: Enhanced motion control and higher sampling rates contribute to more accurate and repeatable measurements.

Greater Versatility: Support for multiple sensor types allows CMMs to handle a wider range of measurement tasks.

Better Data Integration: Improved communication capabilities facilitate easier integration with CAD systems, statistical process control software, and factory automation systems.

Unlocking the Garden: Interoperability and Open Systems in CMM Technology

The move towards more open and interoperable CMM systems is gaining momentum. This shift is characterized by:

Cross-Platform Compatibility: Controllers that can work with multiple CMM brands and software packages.

Open Communication Protocols: Standardized protocols like I++ DME are facilitating easier integration between different components of CMM systems.

Software Independence: The ability to use different software packages with the same CMM hardware gives users more flexibility and choice.

Modular Upgrades: Users can upgrade individual components (like controllers or sensors) without needing to replace entire systems.