You have choices, make the right choice

New release of point cloud inspection software

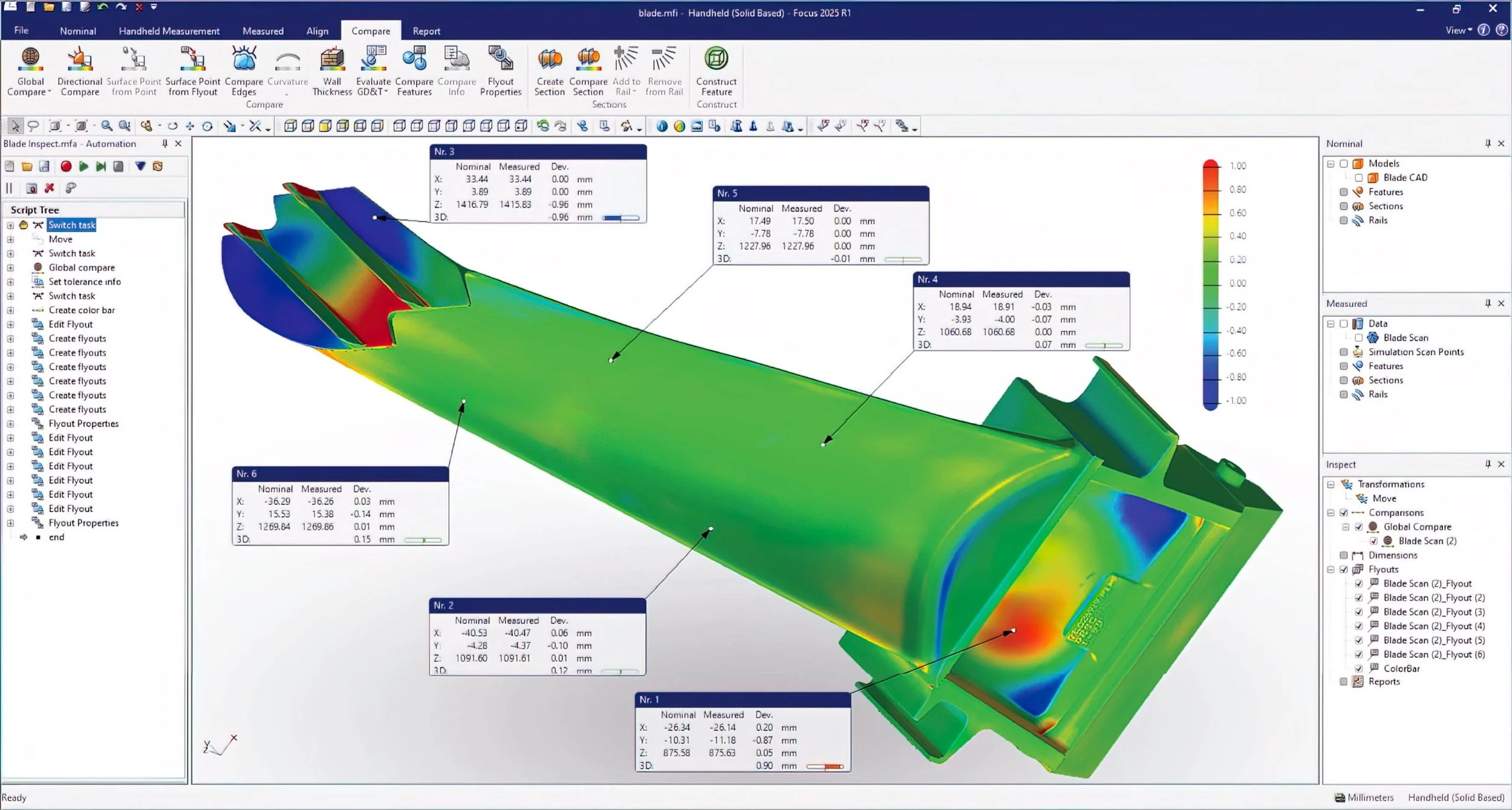

An intuitive point cloud inspection package, FOCUS 2025 R1, has been integrated into the software suite offered by LK Metrology. Branded to align with other products in the company’s range, the easy-to-use, 3D digital inspection software provides users with part-to-CAD comparisons and advanced feature inspection. It includes the latest laser scanner driver NM API 5.0 R1 installer, ensuring optimal compatibility between the software and laser scanning hardware. New also is modernisation of the file menu to a backstage interface, which provides clear visibility of a large set of recent files and their locations.

New release of Point Cloud inspection software

Castle Donington-based LK Metrology has released the latest version of its 3-D inspection software, FOCUS 2025 R1, which now forms an integral part of the company’s metrology suite. Designed to complement LK’s range of portable measuring arms and coordinate measuring machines (CMMs), the software introduces a host of enhancements aimed at streamlining point-cloud inspection and enhancing user experience.

Scanning small parts with GOM Scan 1 and ATOS Q

From plastics to electronics and consumer goods, small parts are everywhere. Their geometries range from simple to complex with fine structures and tiny holes, each with specific measurement requirements. With the 3D scanners GOM Scan 1 and ATOS Q, scanning small parts is easy.

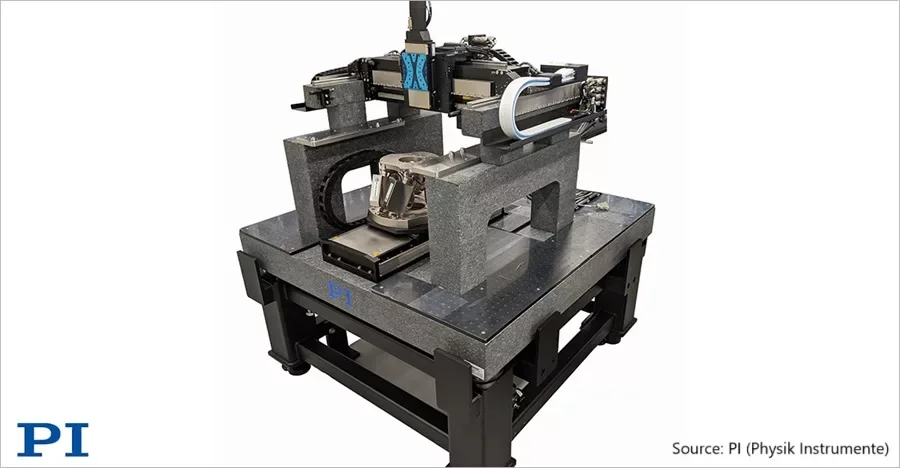

PI USA Engineered Precision Gantry Positioning Systems

PI (Physik Instrumente) offers custom precision gantry motion systems, engineered for high-accuracy industrial applications like inspection, metrology, laser processing, micro-assembly, and high-end 3D printing.

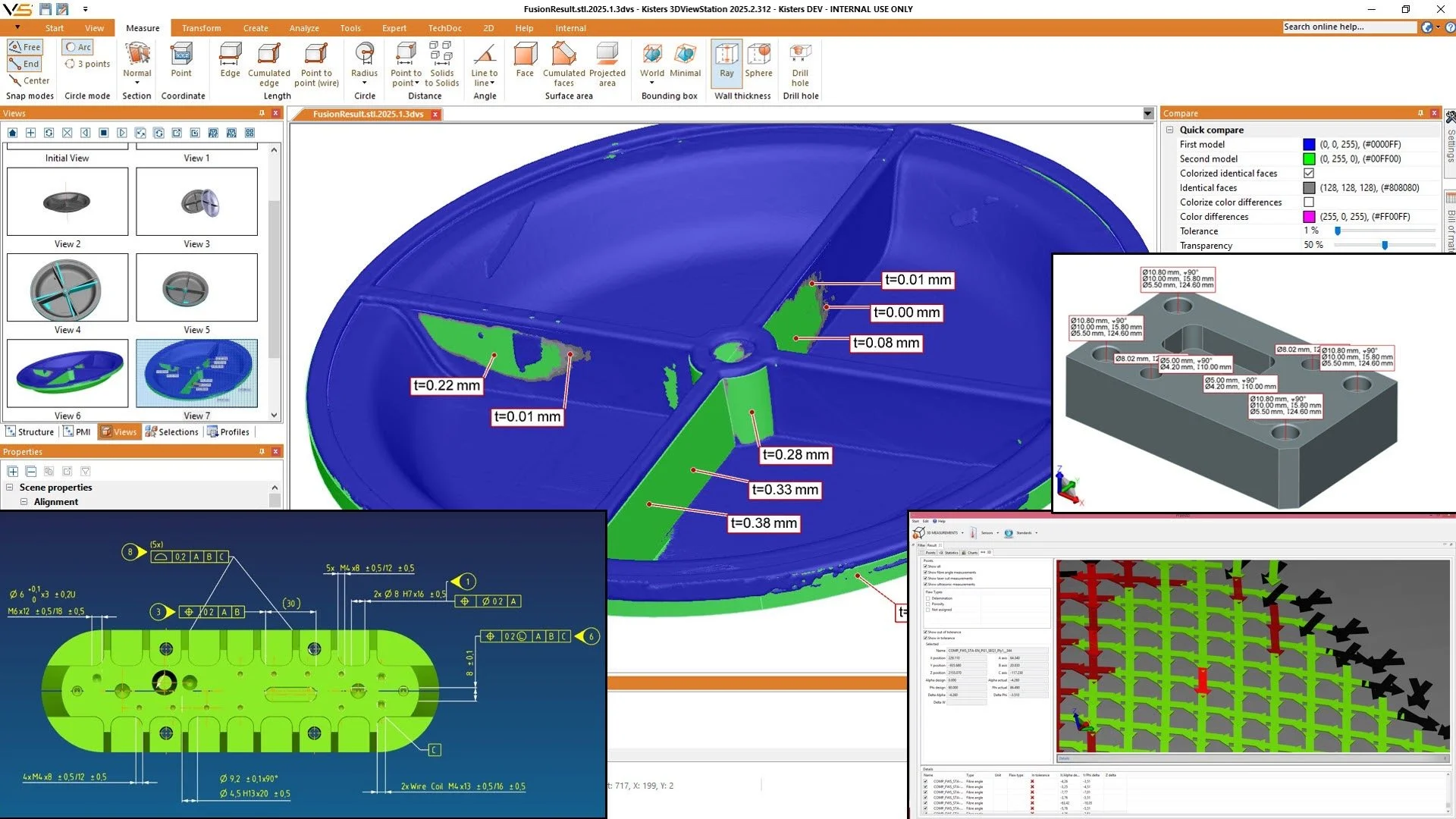

Quality made visible thanks to powerful 3DViewStation graphics

In modern manufacturing, quality is no accident – it is the result of precise planning, comprehensive documentation, and efficient tools. Kisters 3DViewStation provides companies with a powerful visualization and analysis tool that has established itself as an indispensable component in the quality assurance of 3D CAD data. From goods receipt to prototyping to series production approval, the software enables fast, precise, and system-independent inspection of complex CAD models.

Infinitesima’s Metron® 3D Brings Sub‑Nanometre 3D Metrology Inline at SK hynix

Infinitesima has successfully deployed its advanced Metron® 3D 300 mm in‑line wafer metrology system at SK hynix’s DRAM manufacturing facility in South Korea. The tool is now actively used in volume production—a major milestone for in‑line atomic force microscopy.

How Handheld 3D Scanner Helps for Porsche Modifications

For automotive enthusiasts, Porsche isn't just a brand—it's a statement. Known for its precision engineering and distinctive performance, every Porsche model holds a legacy. But even the finest machines can be fine-tuned, and that's where Fabspeed Motorsport steps in, crafting performance-enhancing upgrades for Porsche owners who demand more.

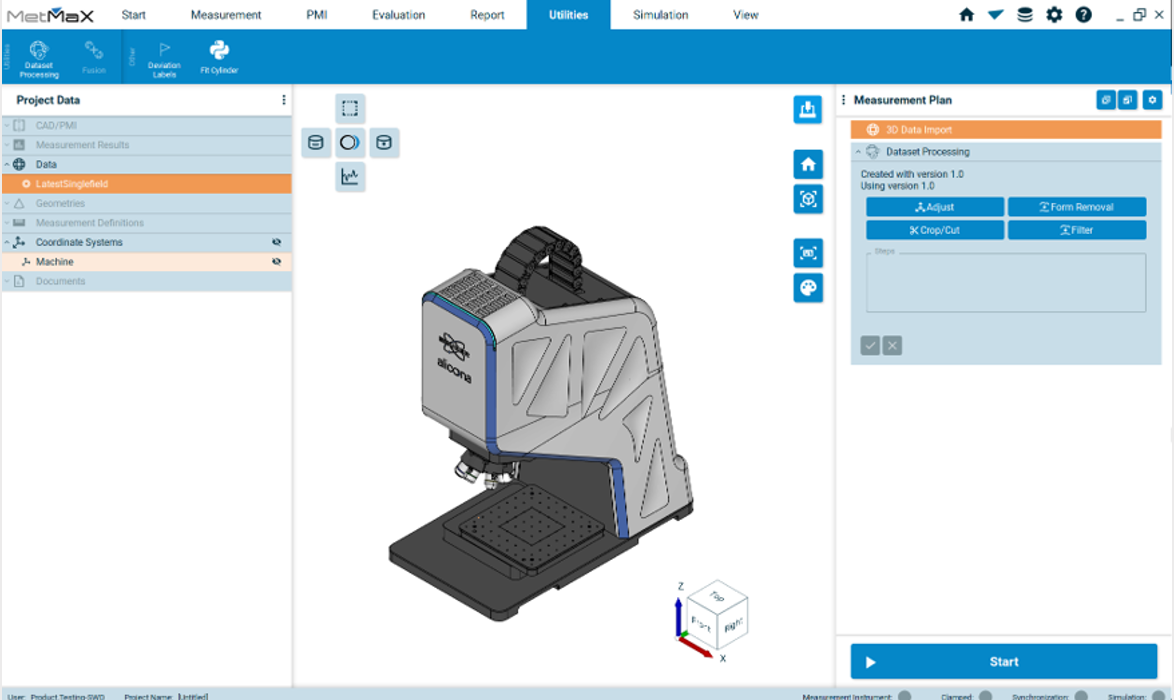

ZEISS introduces ScanPort, a new dimension in semi-automated 3D metrology

With ZEISS ScanPort, ZEISS presents an innovative, powerful solution in optical 3D metrology that combines accuracy, flexibility, and ease of use in a compact system. This new semi-automated system is designed for users who require reliable metrology results - without the need for extensive training or complex setups.

SHINING 3D Metrology Officially Launches: Inspect on the Move

SHINING 3D is proud to announce the global debut of its high-end measurement sub-brand—SHINING 3D Metrology. For over two decades, SHINING 3D has pushed the boundaries of 3D vision technology. Now, with the launch of SHINING 3D Metrology, that journey enters a new chapter—one where precision moves with production.

Faro Technologies Quantum X FaroArm Series

Faro® Technologies, Inc., is advancing the precision and efficiency of sheet metal stamping with its cutting-edge 3D measurement solutions, exemplified by the Quantum X FaroArm® Series.

Hexagon launches MAESTRO coordinate measuring machine for advanced manufacturing precision

Hexagon AB, headquartered in Stockholm, Sweden, has announced that its Manufacturing Intelligence division has launched MAESTRO, a next-generation coordinate measuring machine (CMM). The new CMM is engineered to meet the rising productivity demands of modern manufacturing and meet increasing quality requirements.

LK Metrology launches shop floor CMM series with laboratory-grade precision

Integrating coordinate measuring machines (CMMs) directly into the production environment can significantly boost efficiency, reduce lead times and improve quality control. At Control 2025, LK Metrology will unveil its new Altera SF series — eight robust, high-accuracy CMMs designed specifically for reliable shop floor use.

How SCANTECH’s NimbleTrack Helps Design Custom Wide Body Kits for the Tesla Cybertruck

The automotive aftermarket industry has seen a surge in demand for personalization, with car enthusiasts around the world seeking ways to make their vehicles stand out.

SCANTECH 2025 Global New Product Launch Event: A New Decade Beckons, A New Journey Starts

Under the theme “A New Decade Beckons, A New Journey Starts,” the event brought together industry leaders, technical experts, and partners from around the world to explore the latest advancements and future trends in 3D digitization. SCANTECH unveiled a series of groundbreaking new products, showcasing its remarkable achievements in technological innovation and global expansion.

AGILITY® CMMs with 5-axis technology

AGILITY® CMMs deliver REVO® 5-axis measurement speed, accuracy and flexibility to the shop floor and the lab, with Renishaw's manufacturing quality and innovative technology.

3D Scanner CMM Performs 3D Measurements With AI

The new Keyence VL-800 Series 3D Scanner CMM marks a breakthrough in metrology with the introduction of 3D-AI, making high-quality 3D data acquisition and analysis seamless for any user.

Precision in motion: CMM technology elevates quality standards

Serbian grinding machine manufacturer Grindex has significantly enhanced its quality control and R&D capabilities with the installation of an LK Metrology CMM — enabling faster, more precise inspection, reduced scrap and improved production efficiency.

Contour Scanning powered by Focus Probing Technology

Experience a new era of efficiency and flexibility with contour scanning, an additional application of Focus Probing technology! With significantly increased speed and ease of use as well as extensive automation options, scanning contours is now even faster and more intuitive.

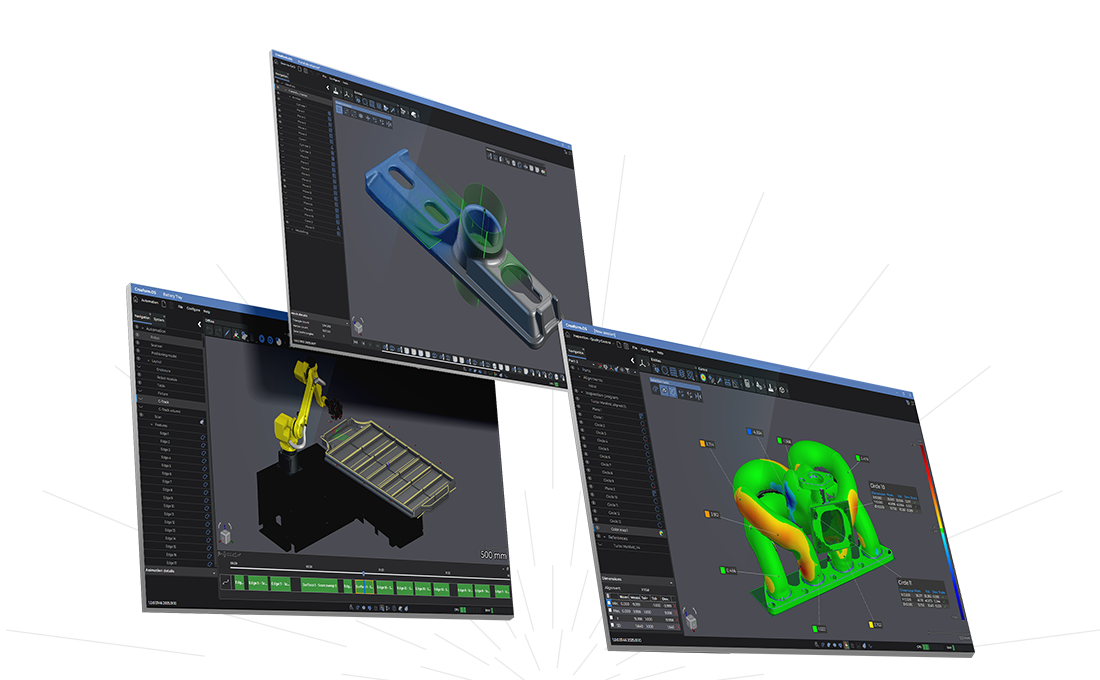

CREAFORM UNVEILS CREAFORM.OS AND CREAFORM METROLOGY SUITE: A LEAP FORWARD IN 3D MEASUREMENT SOFTWARE

Creaform Metrology Suite, its revamped 3D measurement software solutions. Previously known as VXelements, these new platforms focus on an intuitive user experience to streamline metrology workflows, benefiting professionals in reverse engineering, inspection, and automated 3D scanning

Automating Portable Manual CMMs

The evolution of 3D measurement systems has transformed manufacturing quality control, addressing diverse requirements for parts, tools, and assemblies.