In-Process Inspection Integrated with Machine Tools

Verisurf Software Machine Tool Probing (MTP) allows for on-machine milling and inspection with a single set up.

Written By Brian Albright

CAD/CAM-based metrology software provider Verisurf Software has released its Machine Tool Probing (MTP) suite, which supports in-process part inspection directly on machine tools.

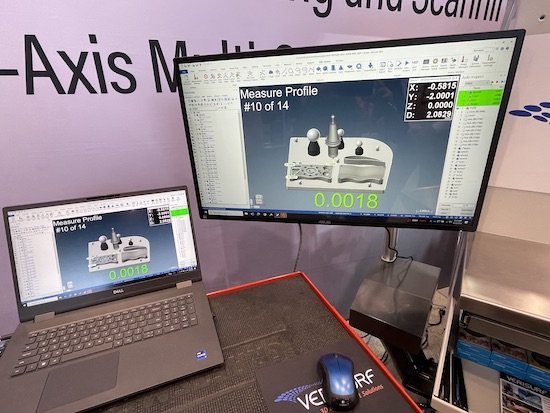

Verisurf demonstrated the MTP solution at IMTS 2024 in Chicago in September. The demo showcased integrated measurement within a milling machine (in this case, a Haas machine), allowing users to mill and measure a part with a single set up.

According to the company: MTP extends Verisurf’s commitment to universal compatibility and offers manufacturers inspection and reporting options beyond typical CMMs. Autonomous on-machine milling, and inspection are accomplished with a single set up. CMM hardware costs are eliminated, parts (especially large parts) do not need to be moved to-and-from the metrology lab, environmental stability is maintained, no additional fixtures or realignment of parts is necessary for measurement, and the closed-loop process improves overall process control.

According to David Olson, director of sales and marketing at Verisurf, this approach is especially helpful for companies that are creating very large parts and tooling.

“It can be difficult to operate really large coordinate measuring machines for big parts,” he said. “You just need a single set up with this solution. You don’t have to take the part off the machine to measure it, and then return it to the milling machine. You can eliminate that additional alignment.”

Verisurf MTP allows users to inspect parts during machining, which improves results and eliminates the need to remove the part from the machine. Image by Brian Albright.

According to a company press release, the Verisurf user interface reflects the configured application modules in a Windows ribbon bar style. New and existing customers can quickly identify and utilize each solution suite’s workflows and underlying features, tools, and capabilities.

Verisurf is built on the Mastercam platform, which allows the CAM and CAI (Computer Aided Inspection) programming to be generated using the same software. The complexity of the programming process and file management is reduced, measurement results can be directly applied to improve machining, and overall process control is improved by closing the loop between the physical machined part and the intelligent CAD model.

The MTP solution, like other Verisurf offerings, is part of an integrated solution to allow for digital continuity across different types of metrology equipment and processes.

“The Verisurf MTP Suite provides extended flexibility when it comes to quality inspection. Our no-code programming and open platform compatibility allow customers to create automated inspection plans with unmatched efficiency that can be executed on any stationary or portable CMM, and now, on all equipped CNC machine tools as well,” said Nick Merrell, Verisurf’s Executive Vice President.