You have choices, make the right choice

Mitutoyo supports future engineers at Babeș‑Bolyai University

With a tradition dating back to 1581, Babeș-Bolyai University, Cluj-Napoca – also known as UBB – is the oldest university in Romania, standing as one of the leading institutions of Romanian academia.

Upcoming Changes in ISO 9001

Ever since the announcement that ISO 9001 would be revised, the internet has been alive with speculation about what will change. Long before any draft documents were available, self-proclaimed experts insisted that the standard would be totally rewritten, or that some new topic would take center stage.

Education, Metrology and Manufacturing in Sync

Vincennes University, Vincennes, IN, a flagship HTEC (Haas Technology Education Center) and Flying S Inc, Palestine, IL, are an example of education working in lockstep with a real-world industry partner.

Metrology: Precision under pressure

In the summer of 2002 a China Airlines 747 en route from Taipei to Hong Kong disintegrated midair and crashed into the Taiwan Strait killing all 225 people on board. The deadliest crash in Taiwan’s history, the accident was later attributed to metal fatigue stress, cracking in the fuselage.

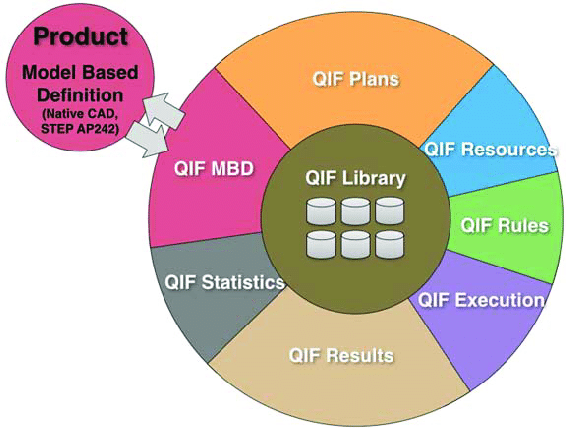

DMIS vs QIF: A Comprehensive Comparison in Metrology

In the field of dimensional metrology, standards like the Dimensional Measuring Interface Standard (DMIS) and the Quality Information Framework (QIF) play crucial roles in ensuring interoperability, data integrity, and efficiency in manufacturing processes.

How Universal Shaft Machines are Redefining Shop Floor Measurement

Although shafts are a foundational component in numerous mechanical systems, including power transmission in automotive and aerospace drivetrains, actuation in hydraulics, micro-rotors in medical devices, and many other variations of turned components in industrial machinery, advances in design and manufacturing have made them increasingly difficult to measure.

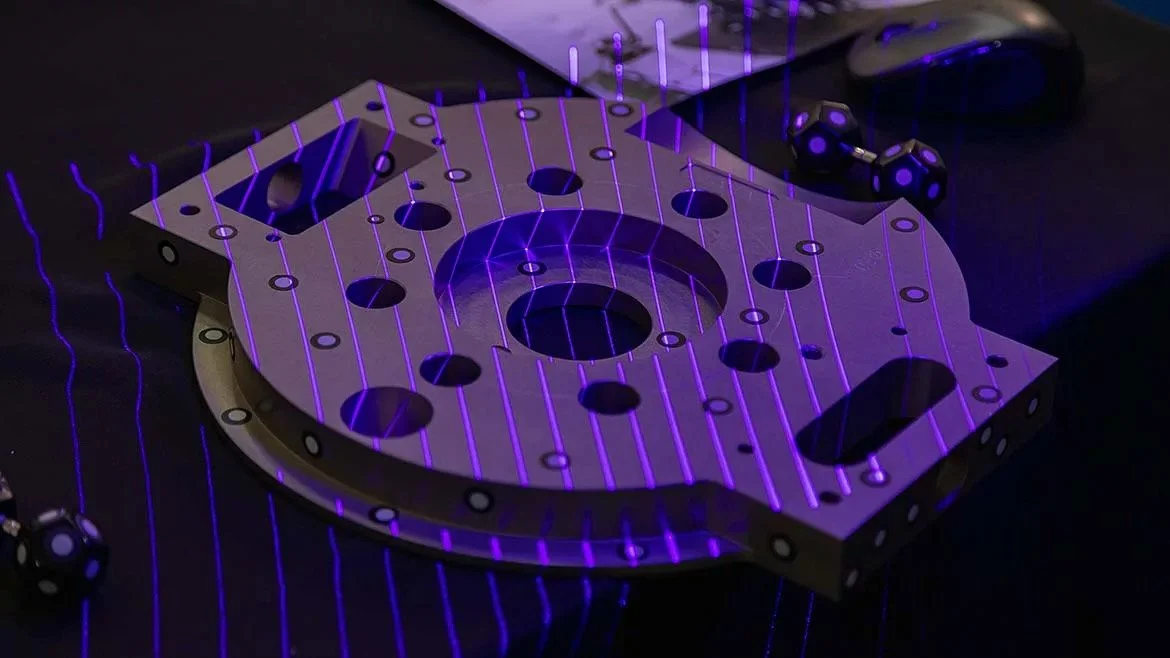

How new metrology and digitalisation technologies are redefining aerospace

The aerospace industry is entering a new period of high-volume production, with Airbus planning to increase its A320 output from around 45-50 per month to 75 by 2026, and OEMs and suppliers around the world working to meet the demand. But with longstanding facilities, skills shortages, and rising pressure to decrease costs, the challenge is not just about modernising how aircraft are made but also about increasing output

Metrology's Role In High-Fidelity Aerospace Manufacture

Metrology is the science of measurement and the invisible backbone of any program that demands parts to fit, move, and survive where margins for error are vanishingly small.

Making Sense of Gage R&R Analysis

The term Measurement Systems Analysis (MSA) refers to a collection of experimental and statistical methods designed to evaluate the error introduced by a measurement system, and the resulting usefulness of that system for a particular application. In manufacturing, measurement system quality directly affects decisions about processes, products, and a manufacturer’s ability to meet their customers’ requirements.

Quality, Manufacturing, and Metrology: The Backbone of Modern Industry

In today’s fast-paced global economy, where supply chains stretch across continents and technology advances at lightning speed, three essential pillars hold up industrial success: quality, manufacturing, and metrology.

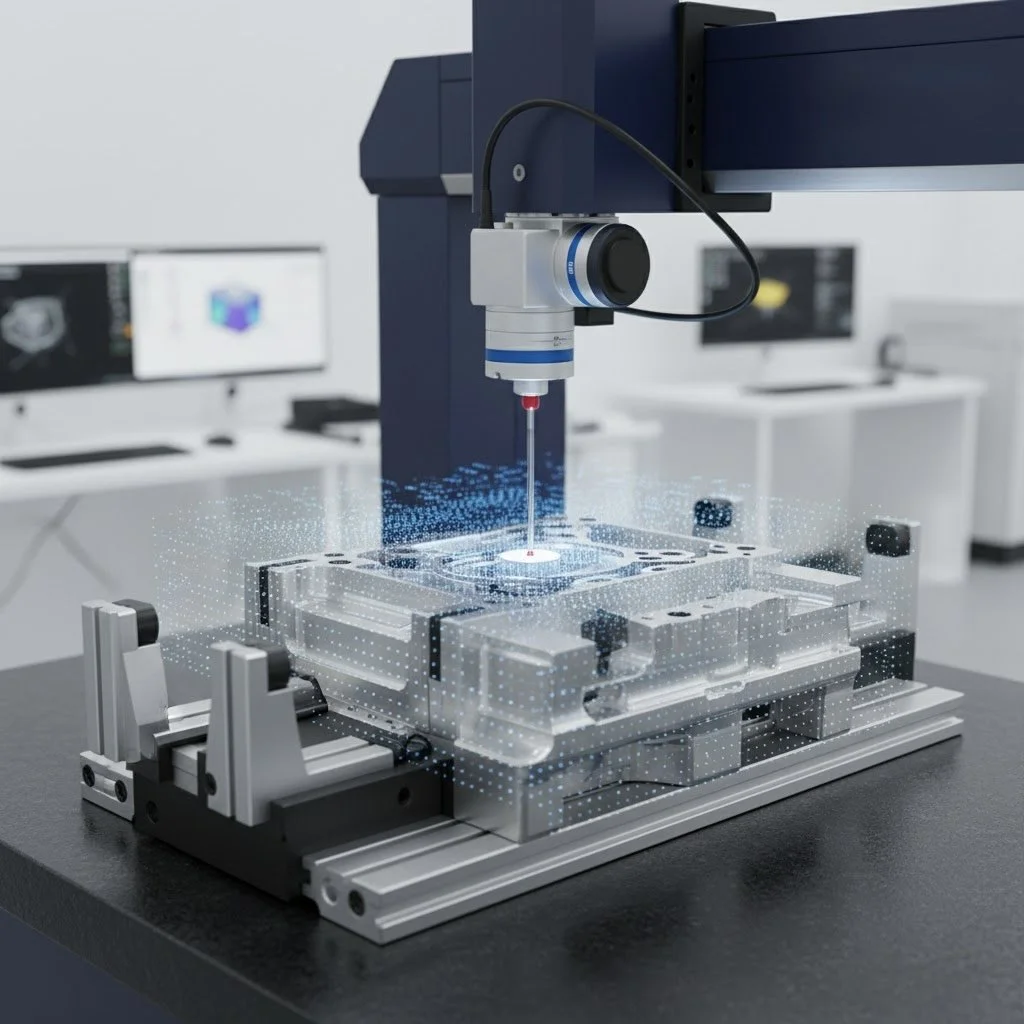

Anchoring Precision: Advanced Metrological Strategies for Primary Datum Plane Establishment on Coordinate Measuring Machines

The integrity of Geometric Dimensioning and Tolerancing (GD&T) specifications hinges entirely upon the stability and accuracy of the Datum Reference Frame (DRF). As the foundation of this framework, the primary datum plane—typically designated Datum A—serves the critical function of establishing the initial orientation and location of a manufactured component in three-dimensional space.

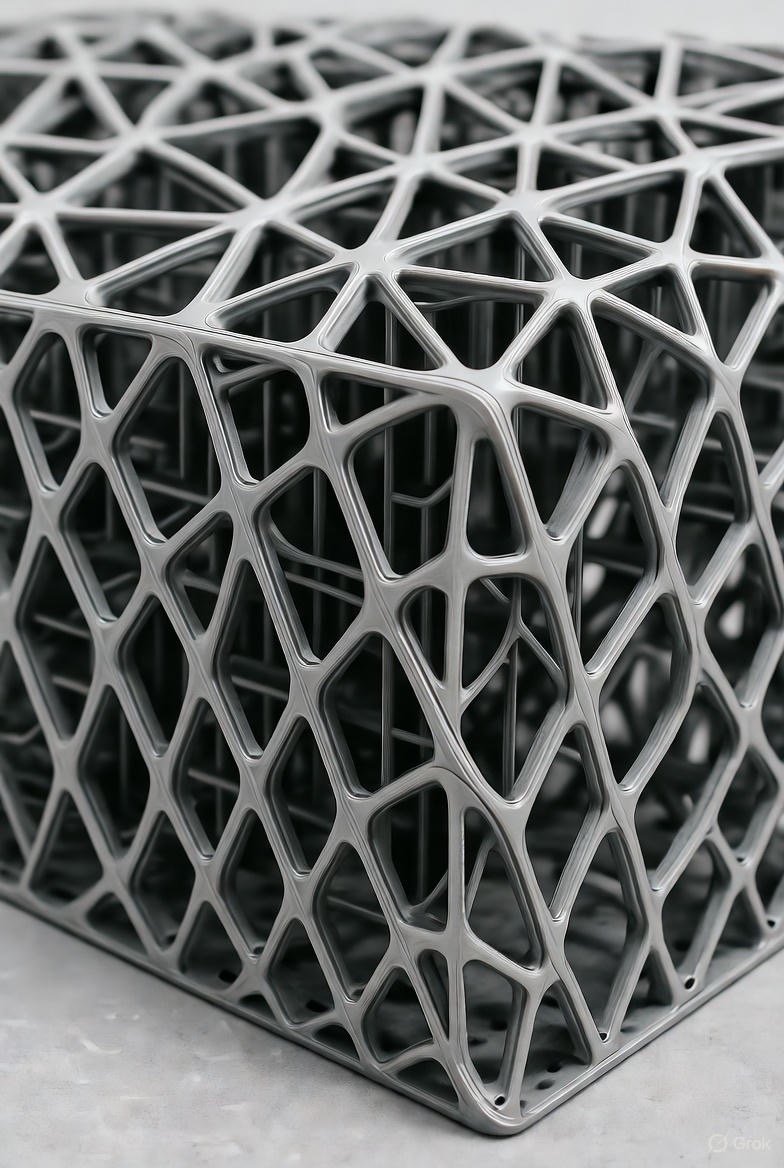

America Makes and ANSI: Driving Standardization in Additive Manufacturing for Enhanced Metrology and Quality Assurance

In the rapidly evolving world of additive manufacturing (AM), standardization plays a pivotal role in ensuring reliability, interoperability, and quality across the entire production ecosystem.

LK Metrology expands into industrial CT by acquiring ProCon X-Ray

Through this acquisition, LK Metrology can now offer its customers an even wider range of products for inspection and measurement from a single source, from traditional CMMs, portable measuring arms and laser scanners to high-resolution X-ray equipment and CT analysis.

Laser scanning transforms inspection of roofing products

Few people outside the tile-making and building industry know that a good quality roof tile has to be manufactured to a tolerance as tight as plus or minus half a millimetre. It places a requirement on the research and development and quality control (QC) functions in that sector to measure prototype tiles and mass produced tile samples to ensure they are accurate.

PRECISION IN MEDTECH: METROLOGY FOR MEDICAL DEVICE COMPLIANCE

In the realm of medical device manufacturing, precision isn’t just a benchmark—it’s a necessity. For metrologists and production engineers, ensuring that each component meets exact specifications is vital for patient safety, regulatory compliance, and product efficacy. This article delves into the pivotal role of metrology in the medical device industry, highlighting advanced techniques, integration strategies, and the benefits of precise measurement.

The Future of Metrology: From Precision to Prediction

The future of metrology is rapidly changing. Instead of merely verifying quality, metrology is now poised to become an active, predictive force that drives continuous improvements throughout the manufacturing process. Today’s advancements in metrology are moving beyond simple measurement to become integral tools for smarter manufacturing systems.

Review: The DMIS Handbook

Here’s a review of The DMIS Handbook, a guide aimed at helping metrologists and CMM programmers master the DMIS language:

The Value of Being a Certified Supplier

In today’s competitive market, being a certified supplier can significantly enhance a company’s reputation, operational efficiency, and business opportunities

Reducing costs and improving productivity with metrology

Margins are under constant threat and businesses need to find ways to reduce costs, improve efficiency and productivity, and drive down waste. Metrology can help alleviate some of these pressures on the business when used efficiently.

TYPES OF METROLOGY: DIMENSIONAL, OPTICAL, AND MORE

In the realm of modern manufacturing, precision is paramount. Whether you’re a production engineer overseeing complex assemblies or a lab equipment supplier ensuring the accuracy of measurement tools, understanding the various types of metrology is essential. This comprehensive guide delves into the primary categories of metrology—dimensional, optical, and others—highlighting their principles, applications, advantages, and limitations.