Verisurf 2025 Software Now Available

CAD/CAM Based Metrology Platform Expands 5-Axis Sensor Support and Adds New Features Across Application Suites

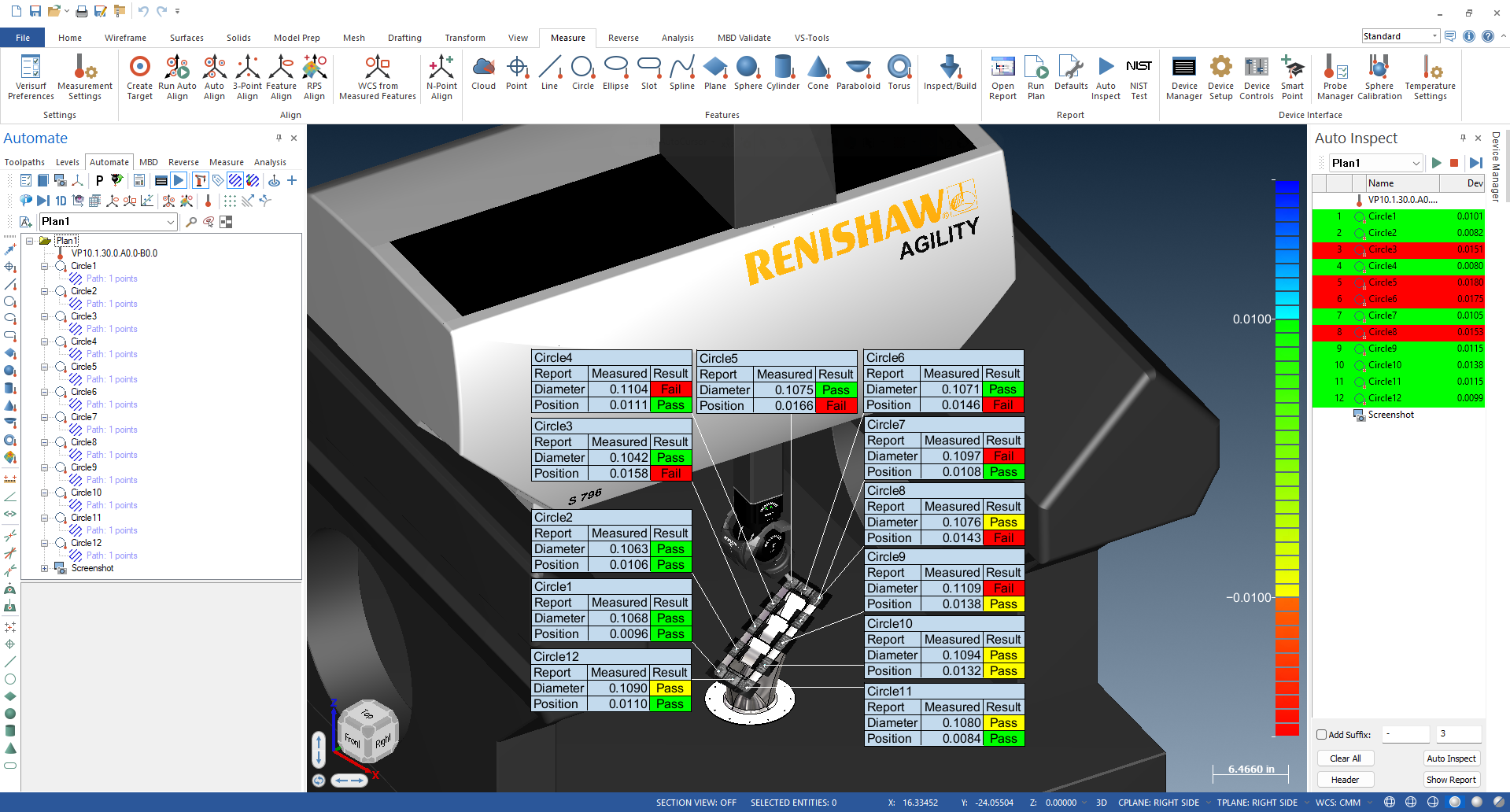

Verisurf Software, Inc. is proud to announce the release of Verisurf 2025. As the only CAD/CAM-based metrology software on the market, Verisurf continues to build on its heritage of intelligent Model-Based Definition (MBD) with new features, enhancements, and optimized workflows for inspection, reporting, reverse engineering, tool building, and guided assembly.

The software is configured in application modules delivered through powerful solution suites designed to optimize the user experience and execution of workflows. The Verisurf user interface reflects the application modules in a Windows ribbon bar style. It provides a familiar user experience and enables new and existing customers to quickly identify and utilize each solution suite’s workflows and underlying features, tools, and capabilities, helping customers maximize their metrology investment.

“The continuing development of the Verisurf platform is rooted in customer applications, evolving technologies, and improving quality and manufacturing-driven requirements. We actively engage with our customers to understand their challenges and successes. This helps us remain customer-centric while providing solutions to today’s challenges and providing a foundation for the future,” said Nick Merrell Verisurf’s Executive Vice President.

A complete list of Verisurf 2025 new features, enhancements, and optimized workflows can be viewed here, Verisurf 2025 Feature Highlights Page.

Verisurf software is designed to support the manufacturing enterprise, whether in the quality lab, on the shop floor, or out in the field. Verisurf solution suites are purpose-based, and additional application modules can be added as needs increase. Verisurf offers flexible licensing options, including subscription, perpetual, standalone, and networkable licenses, as well as license borrowing to meet each individual customer’s needs.

Verisurf Solution Suites

Metrology Enterprise Suite (Includes all application modules)

With Verisurf, customers engage with a familiar, intelligent CAD/CAM environment and powerful metrology tools that enable next-level compatibility and interoperability. Verisurf 2025 powers all measurement hardware devices, including CMMs, arms, scanners, trackers, and all contact and non-contact Renishaw REVO 5-axis sensors.

“Verisurf is about time. Our no-code programming and open platform compatibility allow customers to create automated inspection plans with unmatched efficiency that can be executed on any CMM, stationary and portable,” said Merrell.

Verisurf 2025 enables customers to take full advantage of 5-axis CMM technologies with its no-code 5-axis path planning, designed to provide speed and flexibility without compromising accuracy. Verisurf 2025 powers all Renishaw 5-axis probe systems and REVO’s entire family of sensors, making Verisurf the most powerful Renishaw 5-axis CMM programming software available. Utilizing a 5-axis probe system for inspection provides numerous productivity gains. The number of operations and fixturing is reduced, probe orientation changes are eliminated, and the mass of the machine moves less due to 5-axis behaviors and the head’s infinite positioning capabilities. This minimizes uncertainties and reduces cycle times as much as 3X.

The new Verisurf 2025 release is now available for download from the Verisurf website. All new and existing customers with current maintenance agreements have immediate access.

Verisurf Software, Inc. is a measurement solutions company committed to delivering advanced surface analysis, quality inspection, assembly guidance, and reverse engineering solutions. Verisurf products and processes are vital to maintaining a digital thread throughout design, engineering, manufacturing, and quality. Based on a powerful CAD/CAM platform, Verisurf is a leader in MBD, open standards, and interoperability with all Coordinate Measuring Machines (CMMs) and CAD software. Verisurf solutions empower manufacturers to optimize their product realization process, producing high-quality products in less time and every time.