TrackScan Sharp Series Optical 3D Scanning System

Written by SCANTECH

The TrackScan Sharp series is a cutting-edge optical 3D scanning system, engineered with 25-megapixel industrial cameras and advanced onboard processors for edge computing. This system is specifically designed to measure large-scale parts over long distances with remarkable speed and precision.

One of the standout features of the TrackScan Sharp is its impressive tracking distance of up to 8.5 meters and a high-precision measurement range of 135 m³, which significantly enhances the measurement experience. The system’s robust performance is further highlighted by its 99 laser lines and an exceptional measurement rate of up to 4.86 million measurements per second, ensuring highly precise and reliable results.

Ideal for industries requiring detailed and accurate measurements of large parts, the TrackScan Sharp series sets a new standard in optical measurement technology.

Long-distance and Large-volume Tracking

TrackScan Sharp-S adopts a dynamic adaptive LED algorithm and long-distance depth of field, which supports a max tracking distance as long as 8.5 meters. It allows users to effortlessly tackle a wide variety of challenges including measuring large-scale parts in aerospace, energy, and heavy industry.

Its 135-m3 industrial high-precision measurement range and 233-m3 scanning range are achieved thanks to its large tracking volume, robust edge calibration algorithm, and stable structure. It saves the hassle of moving trackers frequently and enables users to measure large components efficiently in just one position.

Wireless and Easy 3D Scanning

Wireless System

Both the system's 3D scanner and optical tracker have powerful onboard processors for edge computing, which process images and data in real time and output 3D coordinates. Combined with batteries, and external WNICs, it lets users to measure objects wirelessly.

Plug-and-play

The system connects automatically when switched on, without requiring any complex settings, and starts scanning instantly.

User-friendly Operation

Its user-friendly buttons are easy to operate, offering flexible and free 3D scanning.

Excellent and Stable Performance

The TrackScan Sharp-S measurement system features metrology-grade hardware and an innovative in-housed developed algorithm. In this way, the system achieves a maximum volumetric accuracy of 0.048 mm (10.4 m3), capable of meeting stringent industrial requirements for measurements.

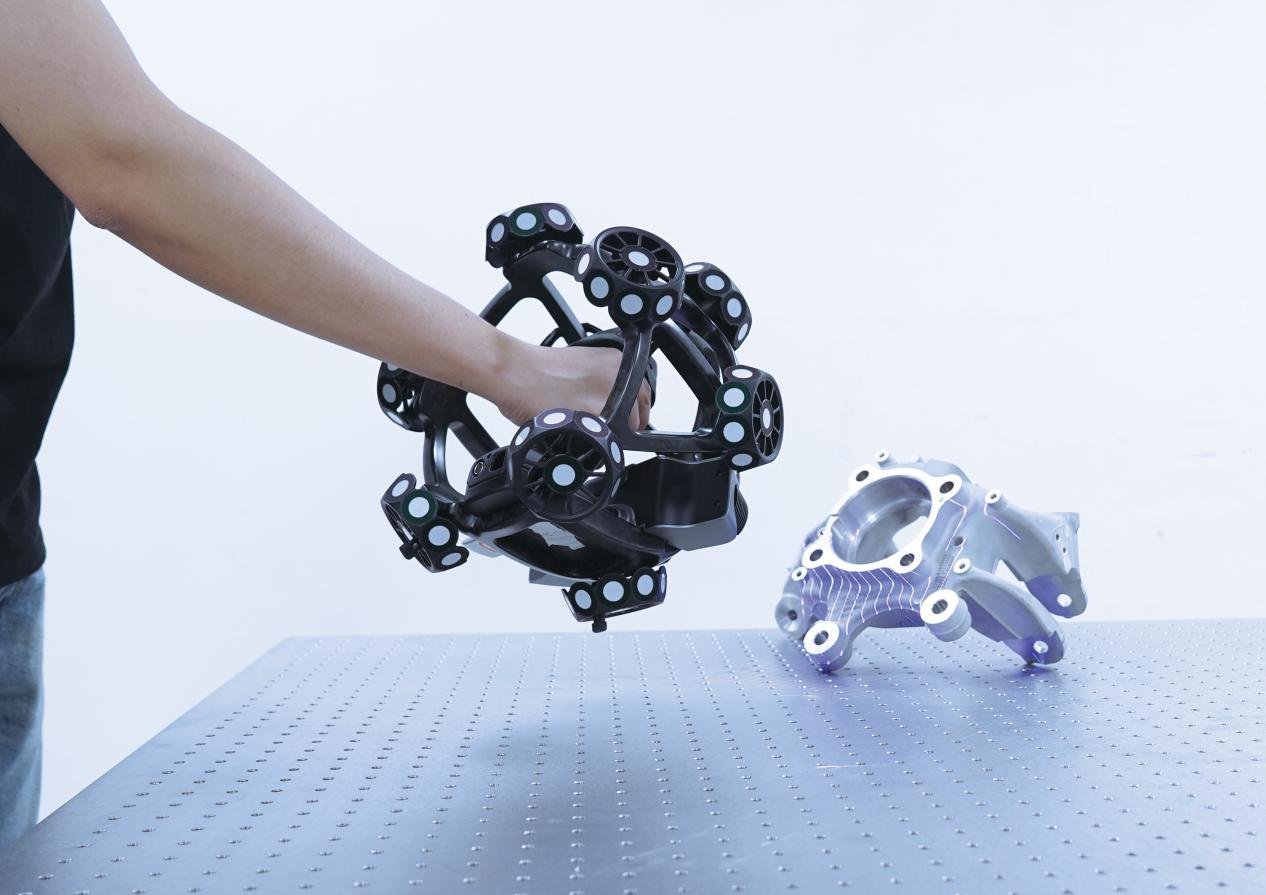

The 3D scanner features an innovative stable structure with CFFIM technology to ensure lightweight design and high strength. Built tough, it maintains a stable performance and it is unaffected by thermal variations to ensure high-precision measurements.

Its integrated structure allows users to grip it from any direction, enabling them to handle and position it freely. Its harmoniously integrated components create a unified and balanced look.

Fast 3D Scanning

Enhanced by advanced hardware and robust edge computing, TrackScan Sharp-Sscans up to an impressive 4.86 million measurements/s with 81 blue laser lines. Whether it is complex aerospace parts or large-scale machinery, TrackScan Sharp-S is ideal to capture 3D data and identify deviations of parts rapidly, which facilitates more efficient and intelligent measurements for manufacturers.

Precise Detail Capture

The system's fine scanning mode powered by 17 parallel laser lines enables it to scan over a large area while generating point clouds fast. This feature provides exceptional detail-capturing efficiency, allowing users to capture intricate details such as slots and corners with high precision and speed.

As a result, parts are meticulously represented in 3D, ensuring accurate and comprehensive digital models.

Versatile Compatibility

● Intelligent edge detection

It boasts an optional function of intelligent edge detection, which is enabled by gray-value measurement. Users can inspect features such as holes, slots, rectangles, rivets, and edges precisely. It is capable of 3D scanning and obtaining information such as positions and diameters.

● i-Probe500

It can be paired with a tracking i-Probe 500 to probe inaccessible areas such as reference holes and hidden points. This contact measurement probe can ensure precise results with both wired and wireless options.

● Multi-tracker measurement

Its measurement range can be dynamically extended by adding more i-Trackers so that it can measure large-scale objects without compromising accuracy.

● Automated measurement

Its brand-new 3D scanner structure is customized to be mounted on a robotic arm more suitably. Its 360-degree distributed target sets allow for all-round and precise tracking. It helps form an efficient batch measurement systems.