You have choices, make the right choice

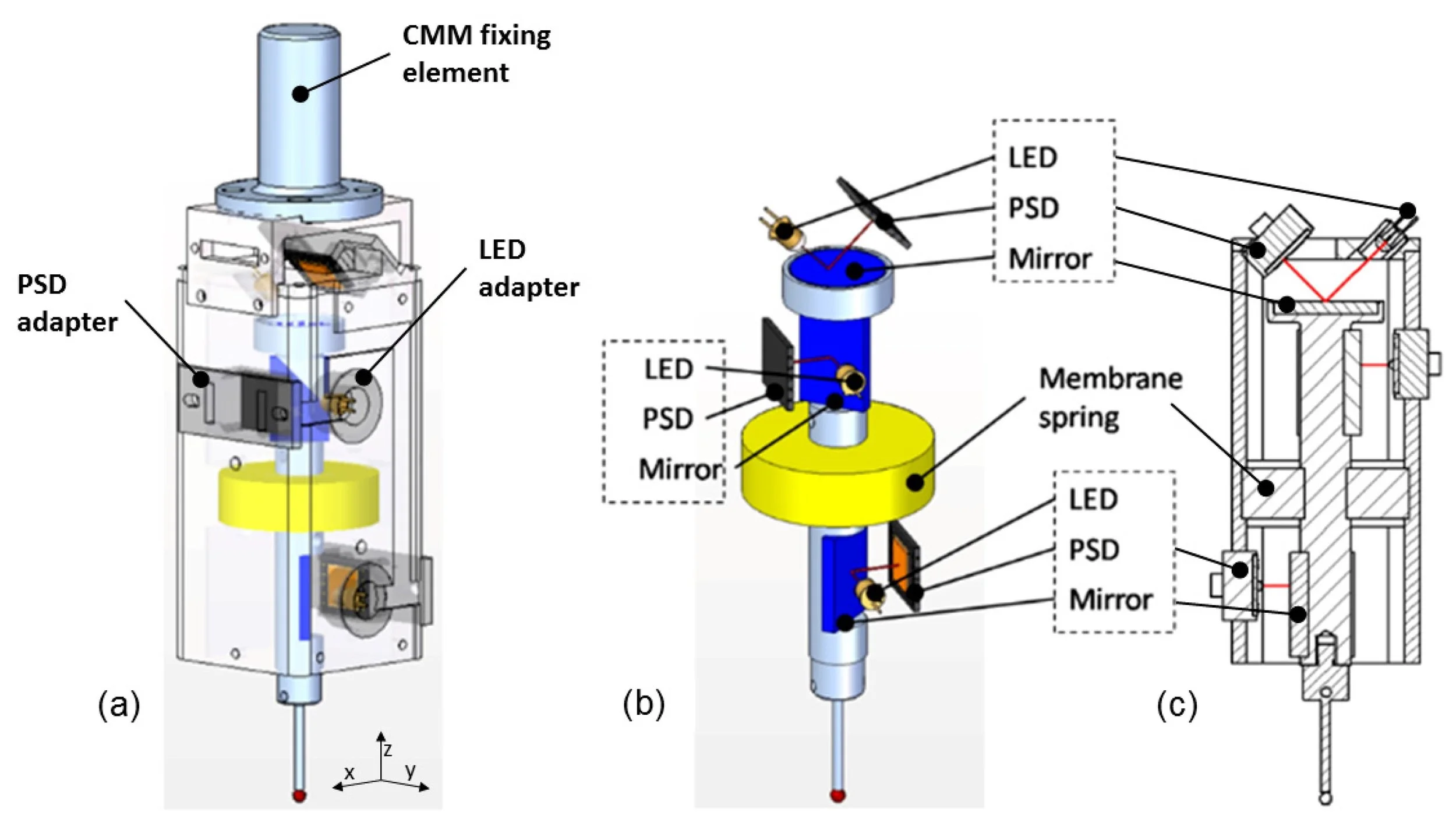

Measuring Force of Scanning Probes of Coordinate Machines

Coordinate measurement technology is a cornerstone in industries like automotive, aviation, and precision manufacturing. The authors note: “The number of coordinate measuring machines (CMM) operating in measurement laboratories and production halls is constantly growing.

Metrology: Precision under pressure

In the summer of 2002 a China Airlines 747 en route from Taipei to Hong Kong disintegrated midair and crashed into the Taiwan Strait killing all 225 people on board. The deadliest crash in Taiwan’s history, the accident was later attributed to metal fatigue stress, cracking in the fuselage.

How Immensa transforms the physical into digital

Dive into the fascinating world of Immensa, a company that's making waves in the supply chain and manufacturing sectors. Immensa is well-known as a supply chain technology company or as an on-demand manufacturer. But what truly sets them apart is their unique ability to transform physical objects into digital assets. Let's explore how they're bridging the gap between the physical and digital!

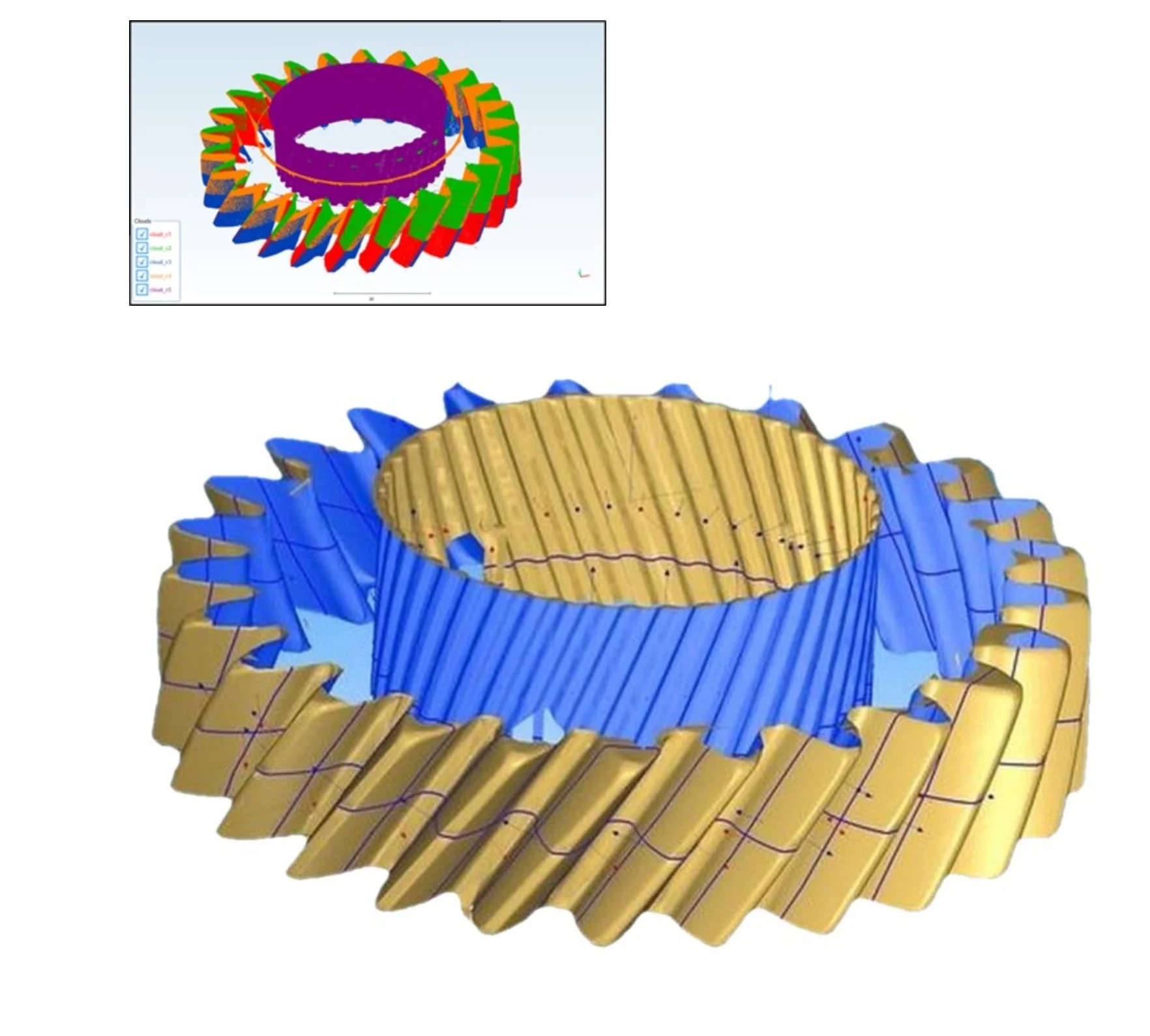

Revolutionizing Gear Inspection

Revolution is a powerful, but sadly overused marketing buzzword, despite the definition, it is often slapped on iterations of existing products, offering marginal gains in performance and/or productivity but still performing the same work, the same way. ZeroTouch Gear inspection respects the definition of the world when claiming to be revolutionary, delivering proven inspection methods where they have not been before, in-line.

Changing the future of transportation with 3D scanning

B-TECHNOLOGY is transforming the future of transportation with an innovative flying-driving drone and the Beccarii car. Utilizing advanced 3D scanning, they ensure precision and quality in their groundbreaking designs.

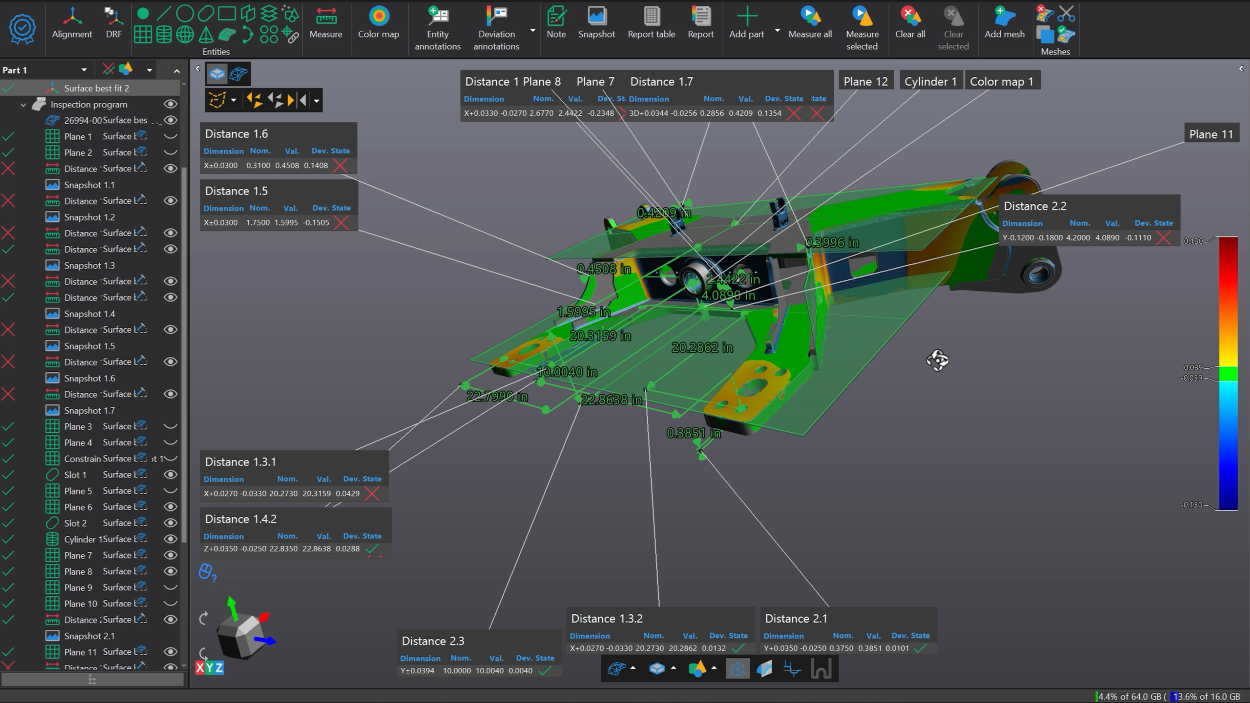

How to choose the right 3D metrology software solution

In manufacturing and quality inspection, selecting the right 3D metrology software solution is essential to ensure accurate results, efficient workflows, and compliance with industry standards. Many companies make the mistake of buying measurement hardware first and then patching together different software tools—which can lead to inconsistent data and wasted effort. In this article, you’ll discover how to evaluate and choose metrology software that supports GD&T, handles large point clouds, integrates across devices, and scales with your operation.

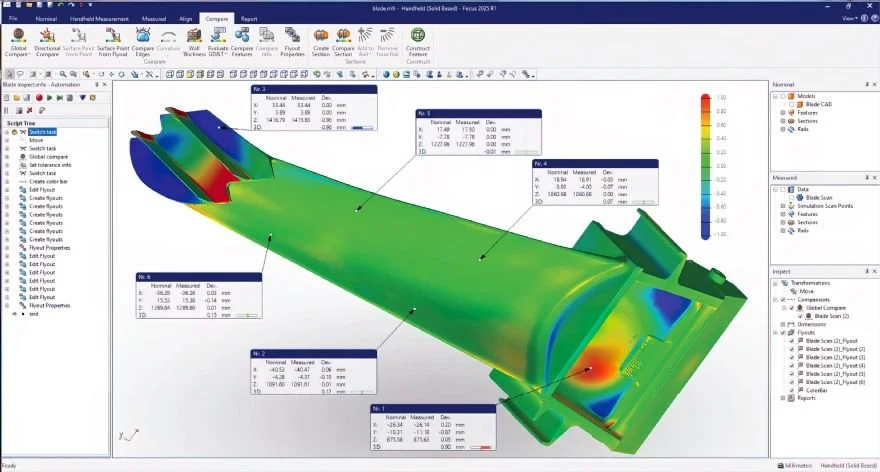

New release of Point Cloud inspection software

Castle Donington-based LK Metrology has released the latest version of its 3-D inspection software, FOCUS 2025 R1, which now forms an integral part of the company’s metrology suite. Designed to complement LK’s range of portable measuring arms and coordinate measuring machines (CMMs), the software introduces a host of enhancements aimed at streamlining point-cloud inspection and enhancing user experience.

The Role of 3D Scanning Technology in Advanced Quality Control Systems

Today’s manufacturing environment demands ever-higher efficiency while maintaining strict product quality standards. The concept of Industry 4.0 addresses these challenges by integrating digital technologies and cyber-physical systems into the production ecosystem. At the heart of this transformation is the implementation of tools that enable real-time data acquisition, rapid adaptability, and minimal human intervention in repetitive or complex tasks.

Custom car-rebuild with 3D scanning solution ZEISS T-SCAN hawk 2 at Girl Gang Garage

Discover how Girl Gang Garage used ZEISS T-SCAN hawk 2 and 3D scanning for a custom car rebuild—covering EV charge-port redesign, reverse engineering, and 3D-printed parts. Learn more in this metrology-driven case study.

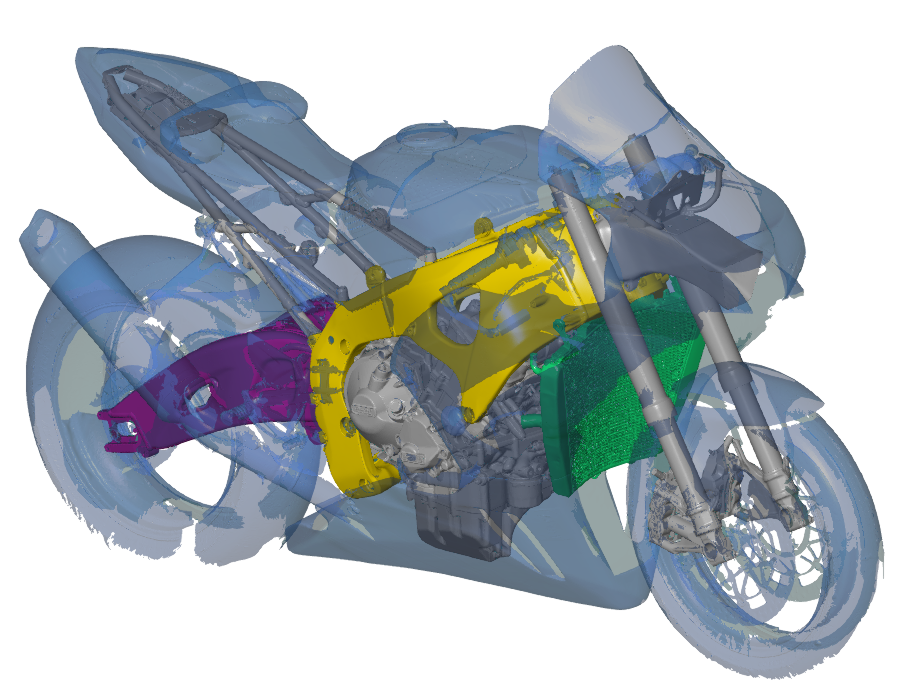

Optimizing electric motorcycles with hand-held 3D scanner

Young engineers have big goals - joining the 24 Hours of Le Mans Moto in France. The twist? Taking part in the competition with the first all-electric motorcycle. The hand-held 3D scanner ZEISS T-SCAN hawk 2 supports them in bringing a functional and powerful motorcycle to the starting line.

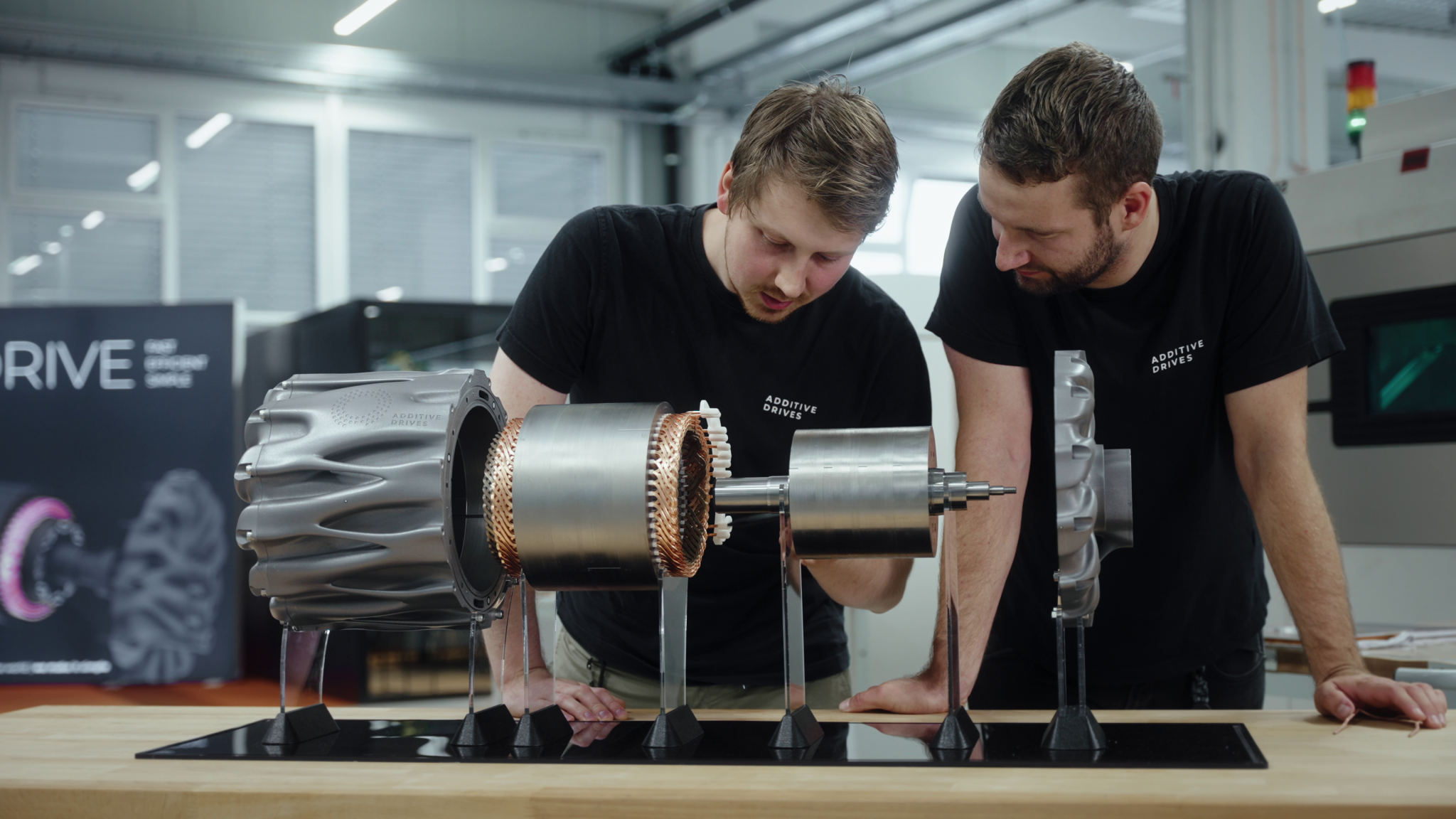

3D scanning and the future of electric motors

Based in Dresden, Germany, Additive Drives is on a mission to simplify electrification. The founders recognized the inefficiency of most electric motors on the market and set out to radically improve electric motor efficiency and power density, not only in automotive but also across aviation, agriculture, and industrial applications.

Scanning small parts with GOM Scan 1 and ATOS Q

From plastics to electronics and consumer goods, small parts are everywhere. Their geometries range from simple to complex with fine structures and tiny holes, each with specific measurement requirements. With the 3D scanners GOM Scan 1 and ATOS Q, scanning small parts is easy.

How Xtreme Manufacturing Improved Quality and Inspection Efficiency Using the HandySCAN 3D|MAX Series

Xtreme Manufacturing offers the largest and most comprehensive line of heavy-duty and high-capacity telehandlers in North America. Known for their rugged performance and reliability in the most demanding environments, Xtreme places a strong emphasis on quality in every stage of production.

Wireless 3D Scanning System Enhances Inspection Capabilities Across Manufacturing Workflows

SCANTECH Co., Ltd., a Chinese provider of 3D measurement solutions, has unveiled its latest innovation: KSCAN-E, the flagship all-in-one 3D scanner is designed to set a new benchmark in wireless, intelligent, and high-precision scanning for industrial applications.

Hexagon unveils Autonomous Metrology Suite for quality control

Hexagon has launched a new Autonomous Metrology Suite to simplify the user experience and accelerate key measurement processes, that it says will cut CMM programming time from days to hours.

Driving Production Efficiency: How FABTEK Optimized Quality Inspection with the FreeScan 3D Scanner

Companies in an increasingly competitive global manufacturing industry are looking to upgrade their technology to improve productivity and product quality. FABTEK Vietnam took a quantum leap forward in product inspection and reverse engineering by introducing SHINING 3D’s FreeScan 3D scanner.

Metrology Automation and Industry 4.0

The key lesson here is that data’s value lies in its precision and dependability. In today’s intelligent factories, every decision and adjustment hinges on trustworthy information. This is where metrology automation steps in, making a significant difference.

How Handheld 3D Scanner Helps for Porsche Modifications

For automotive enthusiasts, Porsche isn't just a brand—it's a statement. Known for its precision engineering and distinctive performance, every Porsche model holds a legacy. But even the finest machines can be fine-tuned, and that's where Fabspeed Motorsport steps in, crafting performance-enhancing upgrades for Porsche owners who demand more.

Artec 3D digitizes Luxembourg’s cultural landmarks for the Luxembourg Pavilion at World Expo 2025 in Osaka

Artec 3D, a pioneering developer and manufacturer of professional 3D scanners and software based in Luxembourg, is proudly showcasing the nation’s rich cultural heritage to the world at Expo 2025 Osaka.

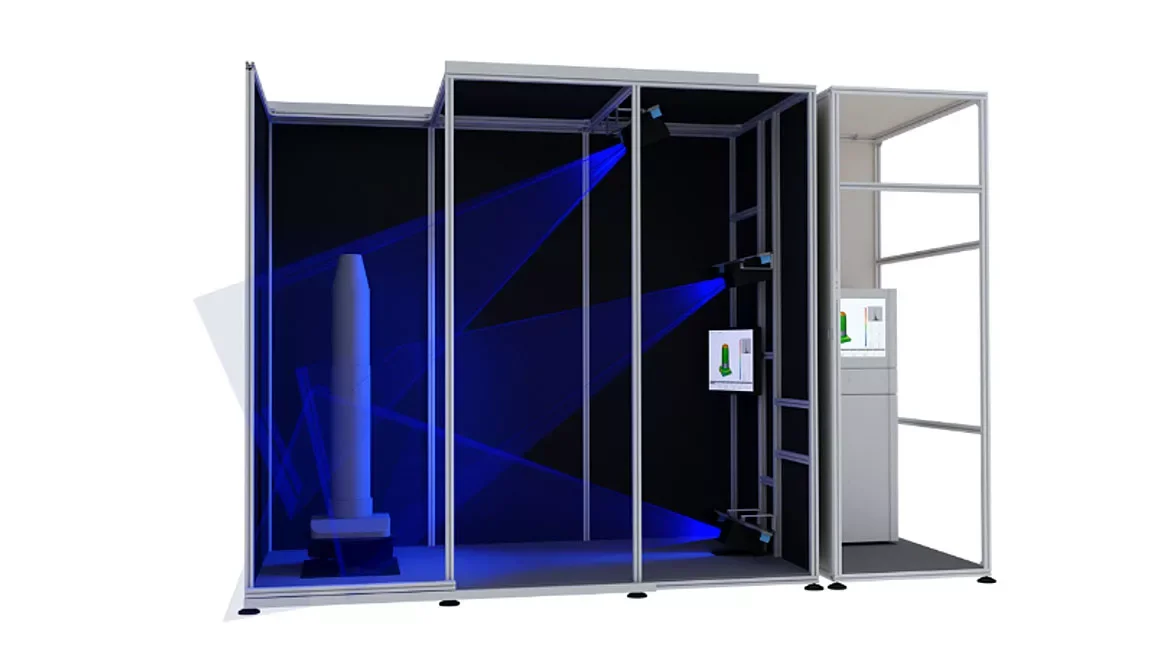

ZEISS introduces ScanPort, a new dimension in semi-automated 3D metrology

With ZEISS ScanPort, ZEISS presents an innovative, powerful solution in optical 3D metrology that combines accuracy, flexibility, and ease of use in a compact system. This new semi-automated system is designed for users who require reliable metrology results - without the need for extensive training or complex setups.