How AI is Addressing Vital Challenges Across the Metrology Value Chain

We’re just beginning to harness deep learning and AI to drive improvements in metrology and quality control, productivity, and competitiveness.

In the struggle to balance market demands for higher quality products with the relentless drive for higher productivity and lower costs, manufacturers are increasingly keen to know to what extent AI is going to be THE answer. Metrology tech providers for their part, are exploring opportunities from the ground up to deliver solutions that ensure quality at unprecedented efficiency.

In March of 2023 after seeing a GPT pass a biology exam, Bill Gates blogged that AI has the potential to save millions of premature deaths and stop climate change. If so, then surely AI could be used to solve simpler problems – like the ones that manufacturers, metrologists and quality control professionals face daily in the production environment. So, what are these problems that metrologists face and how will AI make a difference? In this article we will discuss challenges across the metrology value chain and address some existing and potential AI-driven solutions.

AI advantages – from sales to asset management

Since the launch of ChatGPT, AI has proved to be a huge time saver in roles across all industries. Large language models are being used in ways that make it easier for everyone from sales engineers to product managers to focus on doing tasks where they are strongest and add the most value.

AI has also opened the possibility of using natural language queries in data mining. You no longer need to be a data scientist or python programmer to query a data set. This opens new possibilities for companies to extract insights about machine performance and service patterns from their asset databases. Such insights can be used, for example, to identify opportunities to optimize calibration or service intervals of metrology hardware and production machines.

The data challenge

Of course, any discussion about AI is incomplete without a reference to the vast quantities of data that are required to train models. The issue for metrology companies is that while an abundance of data could easily be collected in the factory environment, collecting and processing this data can be costly, and many companies are reluctant to share their internal data. Therefore, metrology technology suppliers need to communicate a convincing vision of the near-future benefits of AI so that manufacturers can see how sharing their data will benefit them. It also means looking for opportunities to work together on specific projects that can demonstrate its power to deliver value quickly.

AI in metrology product development

Whether the impetus comes from observing trends and developments, or responding to user feature requests, tech companies need efficient ways to keep adding new software capabilities to meet the increasingly complex challenges of modern manufacturing.

Manufacturers are asking for more flexible and intelligent apps to support the shift left in manufacturingand to close skills gaps in the metrology lab and on the factory floor. To meet these needs efficiently, new types of modular software is needed. This means we’re beginning to see an evolution away from the classic types of metrology software.

In the metrology market, the challenge is that the technology leaders are those who have been around longest, meaning that much of their code bases have evolved over decades and do not lend themselves easily to modularization efforts.

In many instances, the code base is also the primary embodiment of the company’s intellectual property – the sole repository or perhaps the only documented source of the company’s specialized metrology or quality control expertise. However, the engineers who have spent their entire careers developing and refining the various flavors of metrology software are approaching retirement, while other people with rich practical experience were laid off during the pandemic. Meanwhile, the young engineers coming on board often lack a deeper grasp of some of the fundamental principles and practices of metrology. Metrology is such a niche topic, and it’s often the case that engineers aren’t exposed to it until their jobs require it.

This perfect storm – the skills gap and the IP challenge – can now be effectively addressed with AI. The idea is to leverage natural language AI to query the codebase, to gain a deep understanding of what each part of the code is doing. In this way AI is helping capture and preserve knowledge, ensuring that critical skills and experience are not lost. Furthermore, this understanding can then be used to rebuild the functionalities in myriad efficient, modular structures.

While initially costly, this approach promises huge long-term benefits. Adopting a modular structure will future proof the software architecture, and the code will be more maintainable and adaptable. Moreover, it will unlock a vast ecosystem of reusable modules, allowing for quicker integration of new features and capabilities in agile development processes and enhanced collaboration with manufacturers to satisfy their specific measurement and QA requirements. Put another way, this structure will support slicing, dicing and repurposing functionalities in unique ways to meet any metrology need.

Examples of current AI-enhanced applications

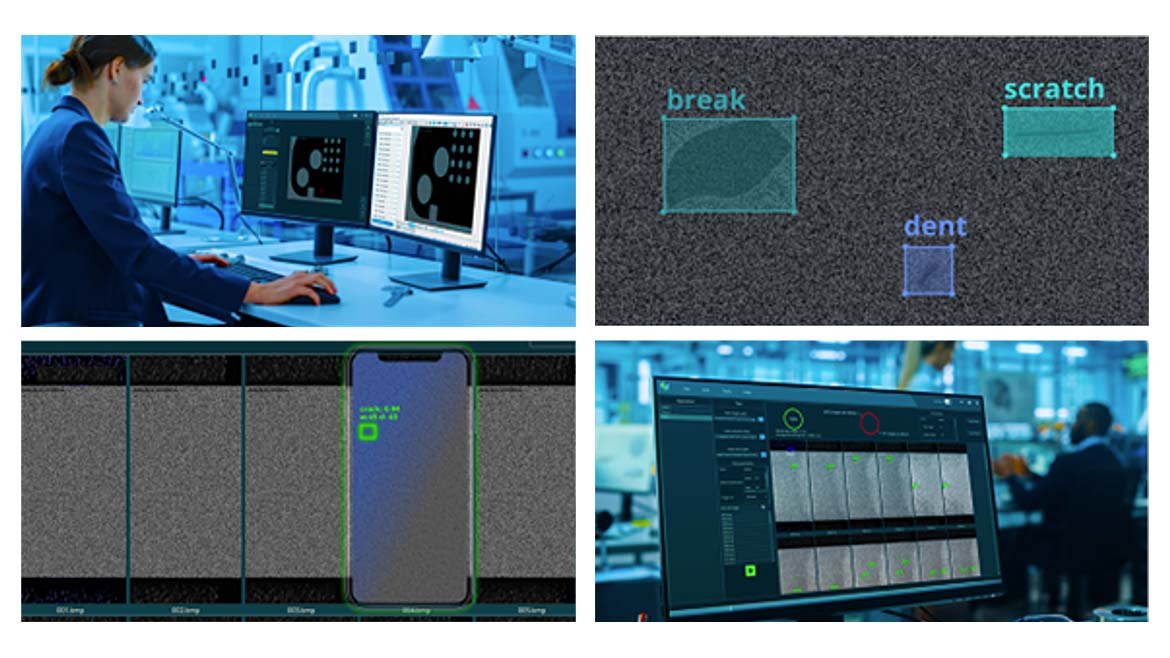

Visual Detection

Leveraging artificial intelligence and machine learning, visual quality control systems can quickly learn from sample images to automatically detect production defects on a wide range of surfaces. Algorithms utilize advanced pattern recognition, statistical analysis, and other image processing techniques to quickly learn about surface deviations. These capabilities are based on deep learning convolutional neural network (CNN) models, which require only a small number of defect samples for their initial training. Thereafter they can be continuously trained to improve their accuracy.

When integrated with vision-based coordinate measuring machines (CMM systems) that use camera-based imaging, AI-enhanced visual detection is a powerful tool in metrology workflows, and it’s easy to reconfigure the system for various products. This enables manufacturers to swiftly respond to product variations without compromising inspection accuracy or speed.

Analysis of Industrial CT data

The power of deep learning and AI is likewise being harnessed in software for the analysis of industrial computed tomography (CT) data. Models can be trained on CT scans and taught to classify, localize, and reliably segment the data into individual parts or regions of interest. Ideal for achieving reliable segmentation results on even low-quality scans typical to inline scenarios, these tools overcome the limitations of standard quality inspection approaches – making reliable, data-driven decision-making much easier.

A noteworthy application of this technology is in the design and production of batteries for electric vehicles. The use of AI/ML greatly aids a full understanding of battery quality and enables improved battery design, manufacture, and end-inspection – maximizing reliability and electrical output.

With anode and cathode segmentation, for example, machine-learning-based capabilities enable the segmentation of each component automatically and is easy to train on individual datasets. When analyzing battery anode overhang, automated plausibility checks ensure reliable segmentation regardless of scan quality. Even more advanced deep-learning capabilities for defect detection and other segmentation tasks are possible using larger amounts of data trained to a manufacturer’s specific quality inspection needs.

Views of battery anode overhang analysis showing the anode overhang in 2D (top) and 3D (bottom)

views where the anodes are coded by color with respect to their corresponding anode overhang.

Image credit: Volume Graphics/Hexagon

Path Planning

Whenever a part needs to be measured using a coordinate measuring machine, laser scanner, or robotic arm the measurement path and point density needs to be planned and optimized to minimize machine motion, contributing to higher accuracy and lower uncertainty. Reduced measurement time and comprehensive coverage of the object being measured are also important goals. This complex challenge requires experienced operators or sophisticated algorithms that consider geometric and kinematic constraints of the measuring system and the object. Now, deep learning is being applied to understand and predict the best probing or scanning strategies for intricate geometries, reducing the need for manual programming or skilled operators.

Quality Forecast

Statistical process control (SPC) systems allow the continuous monitoring of the manufacturing process so that informed actions for continuous quality improvements can be taken. New integrated AI capabilities allow advanced analysis and forecasting of process characteristics.

A recently deployed system predicts future quality value trends based on existing quality data. It’s like a quality weather forecast for quality managers that allows them to act before limits are crossed. The system draws attention to at-risk signals and processes that will become critical, so allowing them to uncover and eliminate hidden root causes.

Tool wear is a good practical example. Using this AI, manufacturers can now accurately predict the optimal time for tool compensations or replacement, ensuring that machine tools are neither overused leading to poor part quality nor replaced prematurely, leading to higher costs.

Machine Chatter and QA – A Near-Future Use Case

Excessive machine vibration is a common cause of quality issues. Imagine a system that ‘listens’ to the noise from the machine and flags a part for inspection when the noise deviates from the norm indicating vibration or chatter. Such systems are available, but they are generally heuristic or rules-based, which makes them less flexible and less accurate. On the other hand, AI-based anomaly detection algorithms which have already proved their value in fields such as online fraud detection, could be applied to the process of milling. The AI would learn the normal sound of the machine when producing a part and then use that ‘knowledge’ to raise a flag any time unusual operation is detected.

The ambition of developers working in this field is to take the timing information from the anomaly detection system and use AI to map it to information from the CAM system so that the QA operator would immediately know which features of the part need to be inspected at a higher density.

Conclusion

We’re just beginning to harness deep learning and AI to drive improvements in metrology and quality control, productivity, and competitiveness. But they are already solving challenges across the entire value chain helping companies produce parts more efficiently and stay competitive against the backdrop of a growing skills gap.

By learning from vast amounts of metrological data AI can detect anomalies, optimize measurement processes and be used to predict optimal maintenance times. Furthermore, deep learning algorithms are available that can start with fewer training samples and then adapt and improve performance over time, refining measurement techniques and reducing errors. It’s beyond question that the value and impact of AI will be enormous.