You have choices, make the right choice

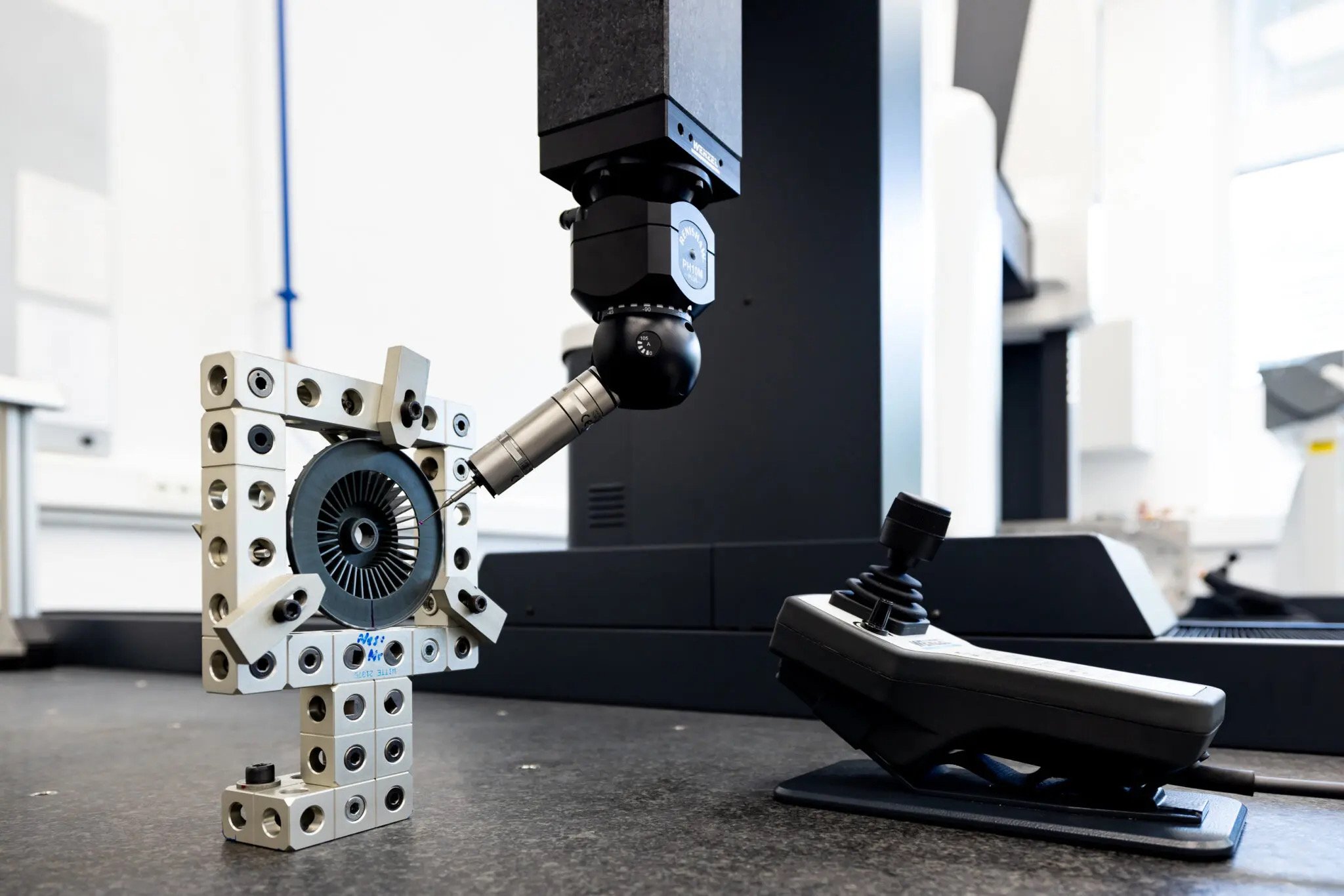

Marine Engineering: 3D Scanning Solution for Ship Turbine Blade Inspection and Product Development

The marine engineering industry plays a crucial role in global transportation and commerce, focusing on the design, development, and production of boats, ships and other marine vessels.

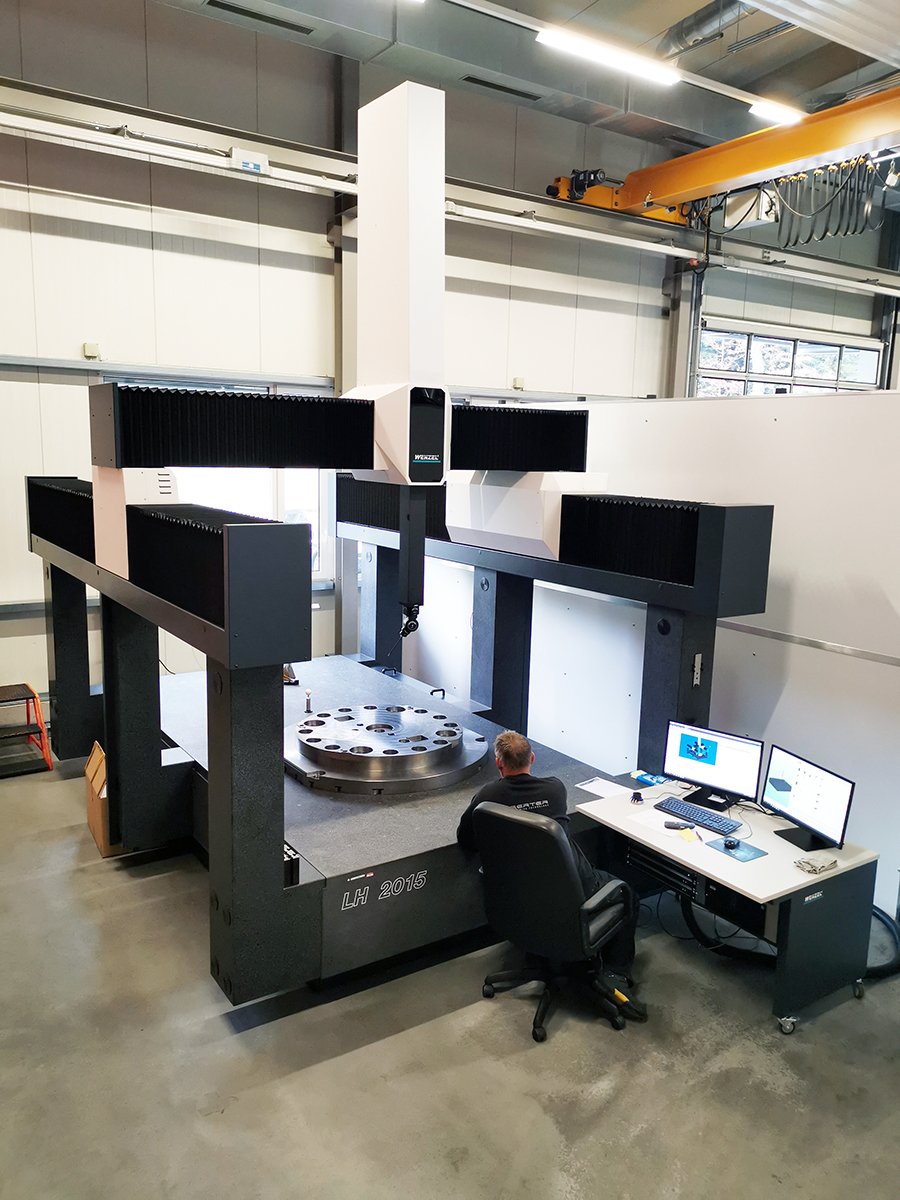

SETTING UP YOUR METROLOGY LAB FOR SUCCESS

When accuracy and precision lead to quality products thanks to excellent internal quality assurance processes, we want to share the success story! Vorwerk, best known for their Kobold and Thermomix brands, is just that story.

3D Scanning and Model-Based Definition: A New Look at GD&T

The increasing quality and accessibility of 3D scanning tools, particularly computed tomography, are giving quality control experts much more information about the parts they look at, experts say.

FARO Releases New Edition to its Portable CMM Series – FARO Quantum X New arm series increases accuracy and boosts user confidence

FARO Technologies, Inc. has announced the release of the Quantum X FaroArm Series of portable coordinate measurement machines. The Quantum X Series offers an up to 15% increase in accuracy compared to previous Quantum Max FaroArms, with probing and scanning designed to improve manufacturing efficiency in a configurable and scalable solution.

Precision and Efficiency in 3D X-ray Microscopy

ZEISS introduces its latest innovation in the field of 3D X-ray microscopy: the ZEISS VersaXRM 730®. This cutting-edge system sets a new standard in performance, choice, and accessibility.

CONSIDER A CMM FOR GEAR INSPECTION

Gear inspection has long been considered a highly specialized, expensive and difficult part of the gear manufacturing process, requiring a wide variety of complicated gages, testers, dedicated CNC equipment and highly trained experts.

But if you want to make good gears, you need to have all that stuff, right?

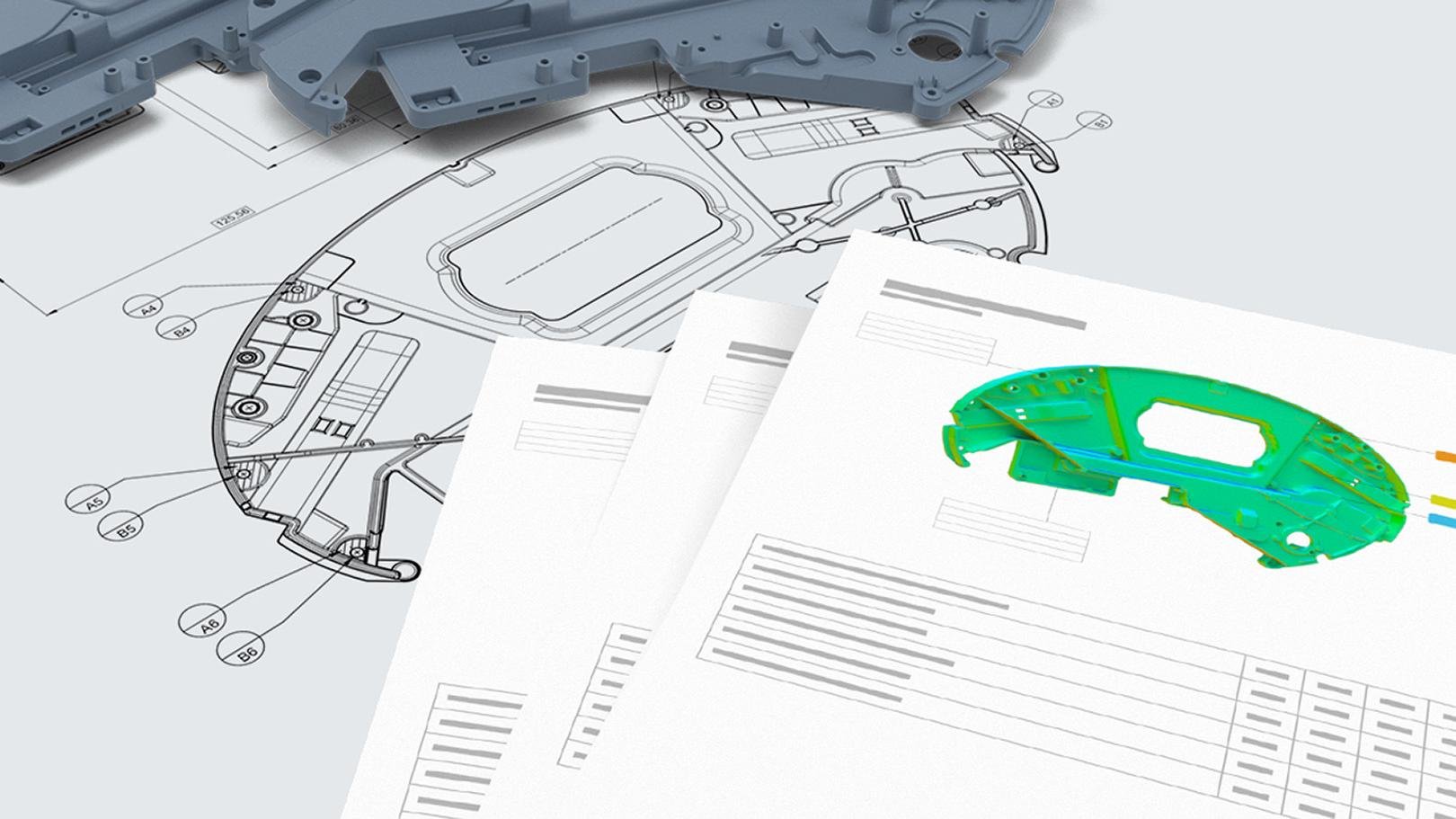

8 Benefits a Mold Builder Should Know about 3D Scanning

By adding extra material to certain parts of a casting, known as machining allowance, engineers enable their machining to the required size, accuracy and surface finish. It is an important way to largely reduce the defective rates of castings.

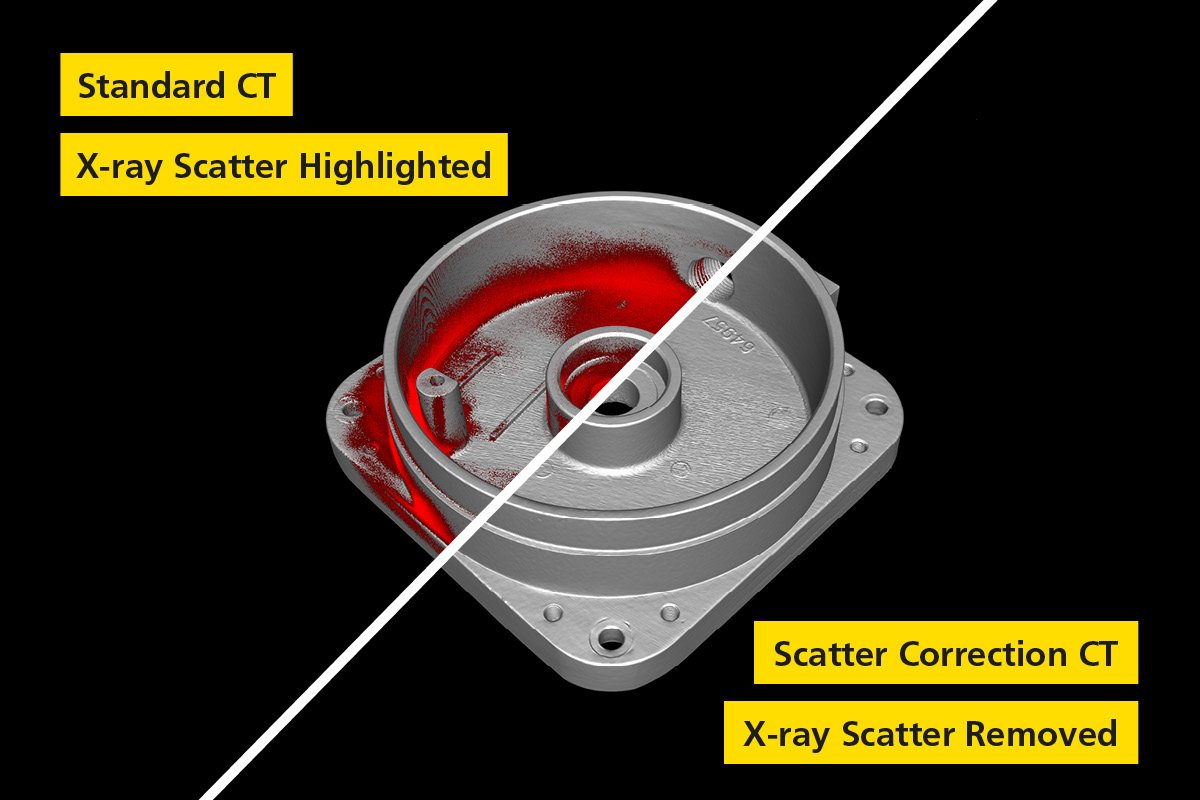

Nikon’s Scatter Correction CT addresses X-ray scatter artifacts in industrial CT scanning

Nikon has announced the launch of Scatter Correction CT, a software solution that enhances image quality and measurement accuracy in industrial computed tomography (CT) scanning by correcting scatter artifacts.

3D SCANNING TO IMPROVE QUALITY CONTROL IN ADDITIVE MANUFACTURING PROCESSES FOR LARGE PARTS

There are tremendous benefits for companies in various sectors to leverage additive manufacturing processes and technologies, such as 3D printing, to create parts that are lightweight, yet strong. From accelerated prototyping to improved agility in customizing designs to significant reduction of surplus part inventory, additive manufacturing brings unprecedented efficiency and cost savings to manufacturing operations.

THE IMPACT OF 3D SCANNERS ON NASCAR STOCK CAR RACING

Reaume Brothers Racing is an American professional stock car racing team that competes full-time in the NASCAR Craftsman Truck Series. Owned by Josh Reaume, the team fields the No. 22 Ford F-150 full-time for multiple drivers, the No. 27 part-time for Keith McGee, and the No. 33 full-time for Lawless Alan.

3D Design and Maintenance on Racing Vehicle with Scantech 3D Scanner

A France 3D Scanning company, BTRD3D, helped LR Motor Company in France to scan the tubular chassis of a race vehicle using the 3D scanner KSCAN 20. The CAD model generated from the scanned data served as a basis for the development of a new product, which means helping the company to conceive a new high-performance buggy for competition.

What are the effectiveness and gains of 3D point cloud inspection?

Point cloud technology refers to the use of a set of data points in a 3D coordinate system, which is commonly defined by X, Y and Z axes. From a metrological standpoint, the actual points in a point cloud represent those X, Y and Z geometric coordinates for each single point.

SMART STEPS TO INTEGRATING 3D SCANNING IN YOUR QUALITY CONTROL

Integrating 3D scanning technology into quality control processes can be challenging. It requires balancing the need for cost-effective, scalable solutions with long-term effectiveness.

ZEISS announces software sales partnership with Artec 3D

ZEISS is cooperating with Artec 3D, a Luxemburg-based technology company that develops, manufactures, and distributes handheld and portable 3D scanners. Under the agreement, Artec 3D will offer ZEISS’ state-of-the-art inspection software as a valuable extension to their range of 3D scanning hardware. The combination of ZEISS software with Artec 3D scanners allows an increasing user group to benefit from an outstanding 3D solution for a broad range of metrology applications.

INNOVATIVE 3D SCANNER SERVING THE LARGEST INDUSTRIAL PARTS A CREAFORM’S CLIENT SUCCESS STORY FEATURING SIEMENS ENERGY

With over 90,000 employees worldwide, Siemens Energy is a global company operating in various sectors of the energy industry, including grid technologies, decarbonization of industries, wind energy, and conventional power generation.

Leica Geosystems reveals new solutions

Leica iCON trades prioritises ease of use and precision from start to finish. The workflow is customised for carpenters, kitchen and stair builders, metal workers, stonemasons and glaziers and covers the entire measurement and templating process in interior construction and finishing, both in 2D and 3D.

Zeiss Inspect Optical 3d

Are you looking to perform detailed evaluation of 3D data? Then ZEISS INSPECT Optical 3D is the software for you! Whether you're an experienced metrologist or just starting out, our software has everything you need for simple and complex inspections, from mesh editing to CAD import, GD&T inspections, trend analysis and digital assembly.

CAPTURE 3D to be known as ZEISS Industrial Quality Solutions as Brand Migration Completes

Today marks the successful migration of the CAPTURE 3D brand following its 2021 acquisition by ZEISS. The completion of the brand migration also signifies the retirement of the CAPTURE 3D company name.

UNVEILING THE HIDDEN HURDLES OF AUTOMOTIVE PART MANUFACTURERS

Manufacturing sheet metal is far from a simple task. It requires rigorous inspection, primarily due to the high quality and stringent safety standards required in the automotive industry. No doubt, a combination of advanced technology and skilled labor must be involved to ensure that the sheet metal components are cut and shaped to precise dimensions. This includes checking for correct length, width, surface profile, and overall shape. Quality inspection is vital because automotive sheet metal must withstand stress and fatigue over the vehicle’s lifetime.