Norelem launches latest line of clamping systems for metrology

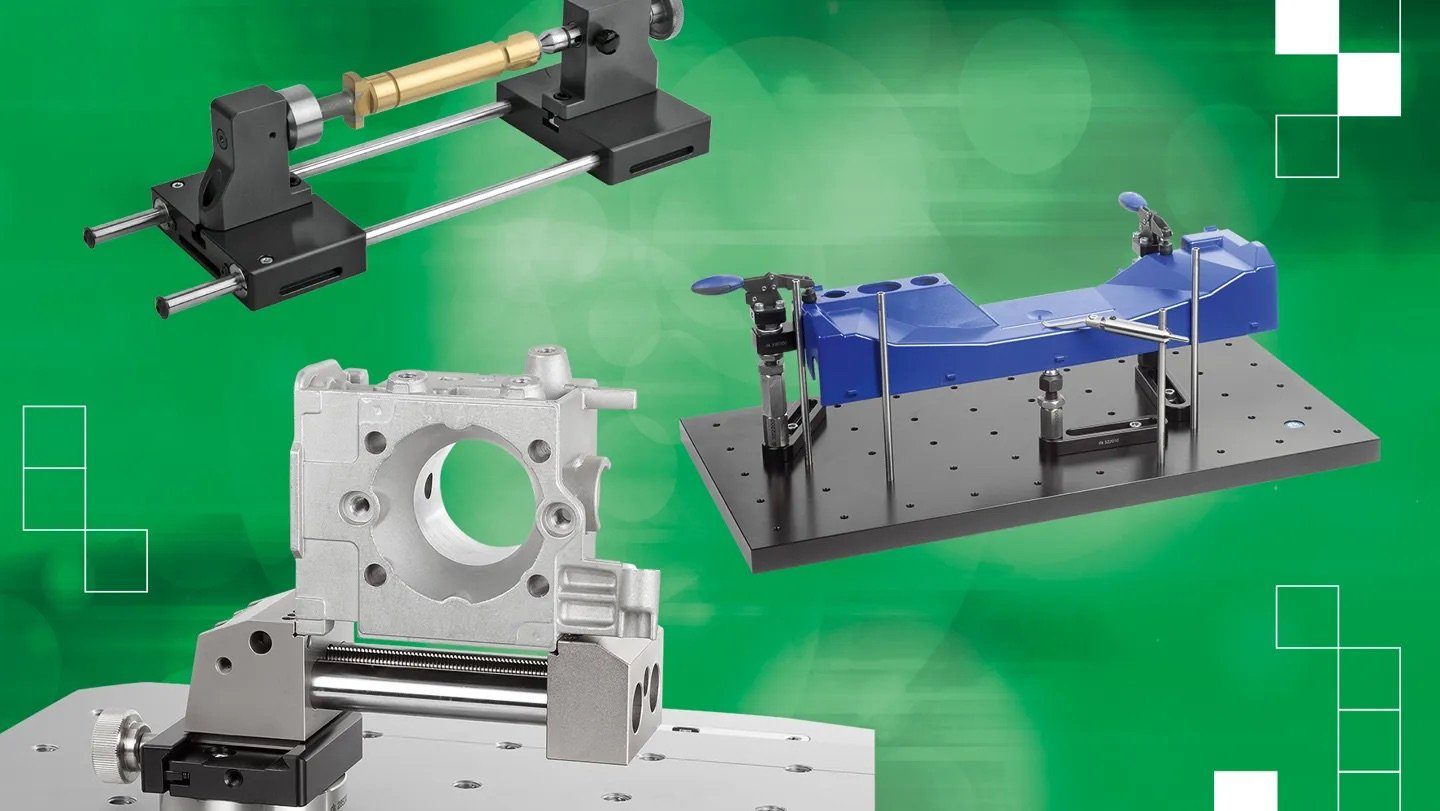

Standard components manufacturer norelem has introduced a new line of modular clamping systems for metrology.

According to the company, its new line of clamping systems can offer significant benefits to engineers and technicians by providing a flexible, modular solution that adapts to the evolving needs of various industries.

Unlike traditional clamping technologies, which require significant force, the company said its systems are designed to use minimal clamping force, offering quick and efficient constructing for even the most complex setups.

For engineers, this could enable faster workflows, reduced fatigue and fewer errors, translating into higher productivity and better measurement accuracy. The system’s flexibility also extends to a wide range of applications, from labelling and laser technologies to handling and the food industry.

In a statement, Marcus Schneck, CEO of norelem, said: “In addition to its versatility, the clamping systems are made to handle both single-time fixation and recurring measurement tasks. Should additional procedures be required, the modular design allows the systems to be easily adapted to meet those specific demands, ensuring engineers can always stay one step ahead.

“At norelem, we offer solutions that support various measurement techniques, from tactile measurements on coordinate measuring machines, to optical measurement procedures and surface and contour measurements. Our systems are built to offer engineers the flexibility they need in any scenario.”

The modularity of norelem’s clamping systems is further enhanced by its range of combinable standard components, the company said – such as base holders, mounting modules, manipulation units and clamping elements. This means that engineers can quickly assemble new configurations or reconfigure existing setups with ‘minimal disruption.’

The system's resource-efficient and cost-effective nature is said to save time and materials, while its uniform interface ensures that all measuring points are accessible in a single setup, simplifying the measurement process and reducing the risk of user error.

“We have made the assembly and reconfiguration process easier by creating clamping component sets specifically designed for coordinate measuring machines, surface and contour measurements, and optical measurement systems,” Schneck added. “These sets contain a predefined selection of foundation, mounting, and clamping pieces, which enable users to easily create both simple and complex setups.”