Simultaneous Requirements in GD&T: What They Are & How They Work

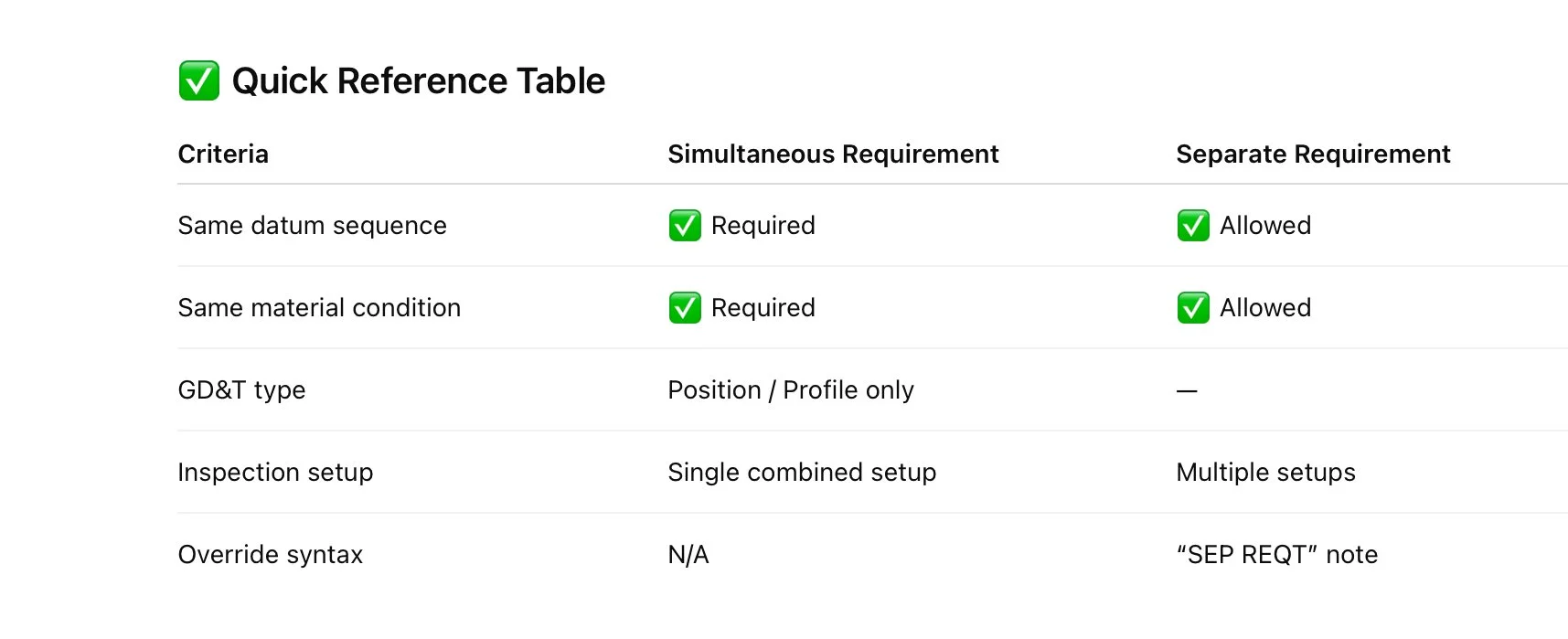

Geometric Dimensioning & Tolerancing (GD&T) uses symbolic language to control geometric relationships. A simultaneous requirement means multiple features must meet their geometric controls together—in the same setup and referencing the same datums in the same order and material condition.

What is a Simultaneous Requirement?

Definition: When two or more position or profile tolerances share identical datum sequences and modifiers, they form a single pattern. The features are then checked simultaneously—relative to each other and the datums.

Key Conditions:

Same datum features in the same order

Same material condition modifiers (MMC/LMC)

Applies only to position or profile tolerances

Why It Matters

Inspection Integrity: Features are inspected in one setup, preserving their true relationship.

Functional Fit: Ensures parts behave as a cohesive pattern—essential for mating components or assemblies.

Tolerance Movement: If datums are at MMC, the entire pattern can shift—but maintains feature-to-feature alignment.

Visual Examples

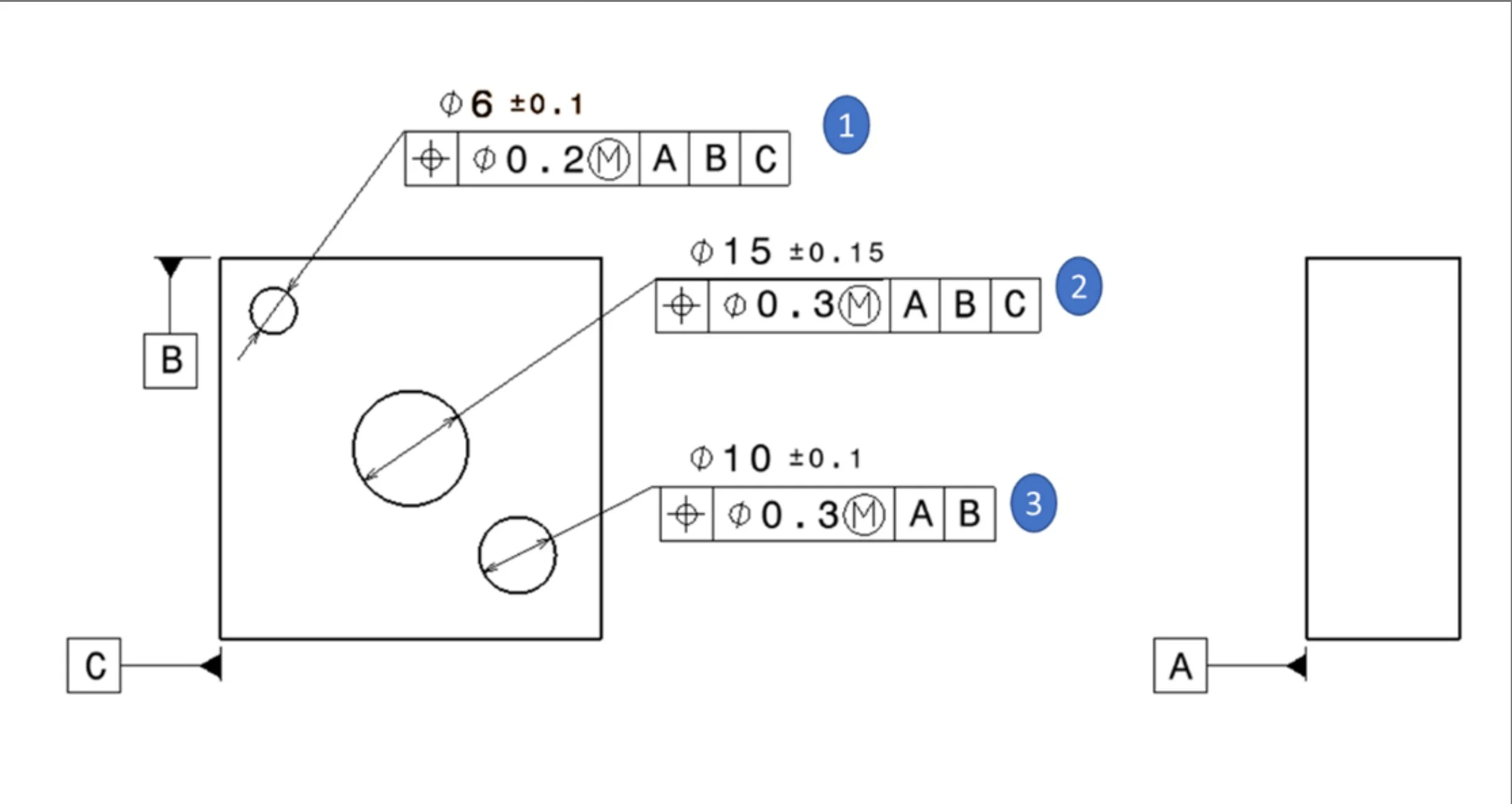

Plate with three holes

Holes 1 & 2 share identical datum reference frames → simultaneous

Hole 3 references different datums → inspected separately

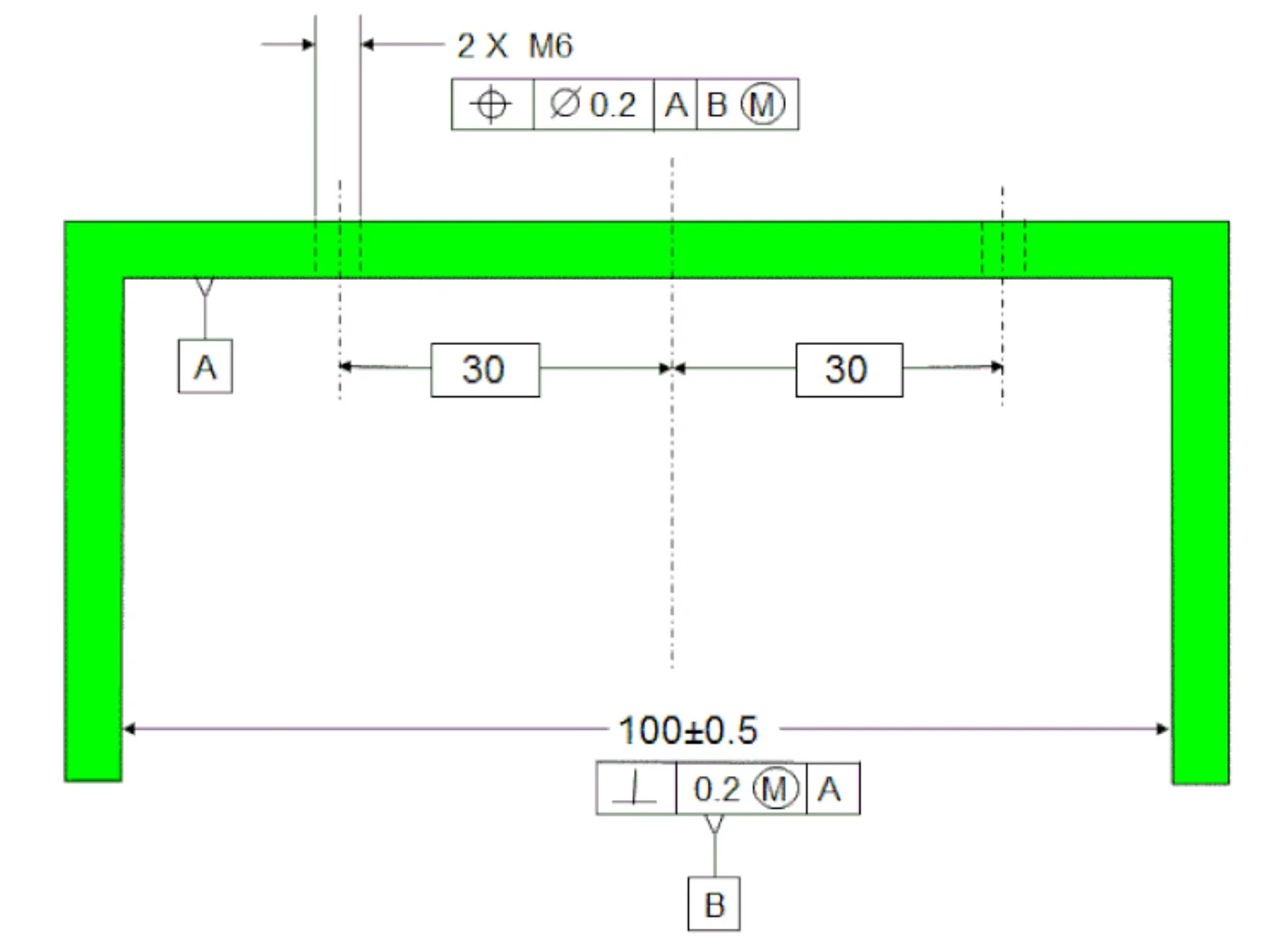

Tolerance stacks on a plate

A note like “SEP REQT” overrides simultaneity.

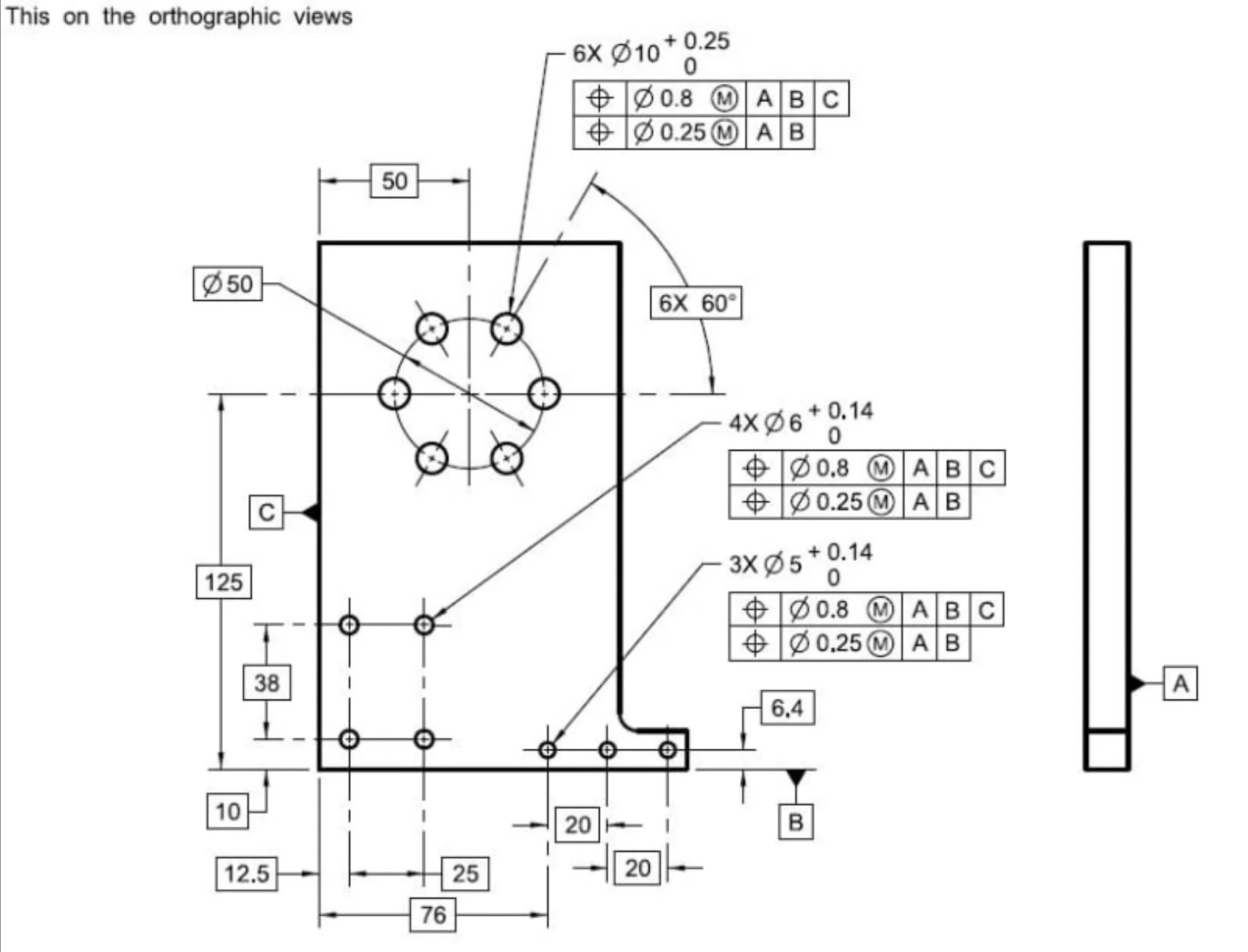

Pattern of holes (engineering forum)

Same datum reference frames tie holes together in a larger pattern

Multiple position controls can still compose a unified pattern.

When to Override: “Separate Requirement”

Place a “Separate Requirement” note under a feature control frame to break simultaneity—even if datums match.

This tells inspectors to gauge features independently.

Design Intent: Use It When…

Features must relate directly in functionality or assembly

You want to minimize gaging misses by preserving feature interrelationships

You need to optimize tolerance without sacrificing alignment

Common Pitfalls

Ignoring material condition modifiers—can break simultaneity

Omitting “SEP REQT” when separate inspection is intended

Misapplying to tolerances other than position/profile

Summary

Simultaneous requirements are a powerful GD&T feature enabling you to control multiple features as one cohesive group—ensuring consistent inspection and functional alignment. Use them when domestic relationships matter, and break them only with intent.

For deeper study, review ASME Y14.5 sections on simultaneous requirements.