You have choices, make the right choice

ZEISS celebrates 100 years of advancing innovation in the U.S.

Today, ZEISS marks 100 years of operation in the U.S., helping Americans improve lives and reach profound achievements by applying the company’s innovative technologies to research, healthcare, manufacturing and more

Innovative Products in Metrology for 2026: Trends and OEM Advancements

As we approach 2026, the field of metrology—the science of precision measurement—continues to evolve rapidly, driven by the demands of modern manufacturing, aerospace, automotive, and emerging industries like electric vehicles and additive manufacturing.

New Benchmarks in Quality Inspection and Data Analysis

ZEISS Industrial Quality Solutions (ZEISS IQS) announces the latest software updates for ZEISS INSPECT and ZEISS PiWeb, addressing the growing challenges of industrial quality control. By providing holistic solutions ZEISS IQS enables end-to-end inspection processes and streamlined workflows.

ZEISS METROTOM 800320 kV

ZEISS METROTOM 800 320 kV is designed for high-precision inspection and metrology of dense materials like Inconel, Cobalt Chromium (CoCr), and additively manufactured metal parts or multi material assemblies.

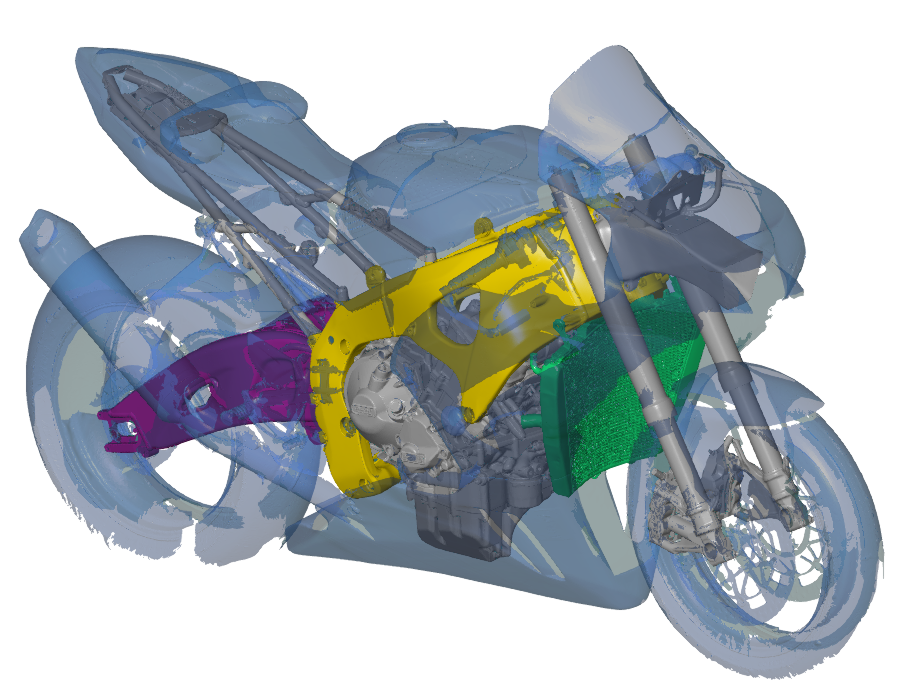

Optimizing electric motorcycles with hand-held 3D scanner

Young engineers have big goals - joining the 24 Hours of Le Mans Moto in France. The twist? Taking part in the competition with the first all-electric motorcycle. The hand-held 3D scanner ZEISS T-SCAN hawk 2 supports them in bringing a functional and powerful motorcycle to the starting line.

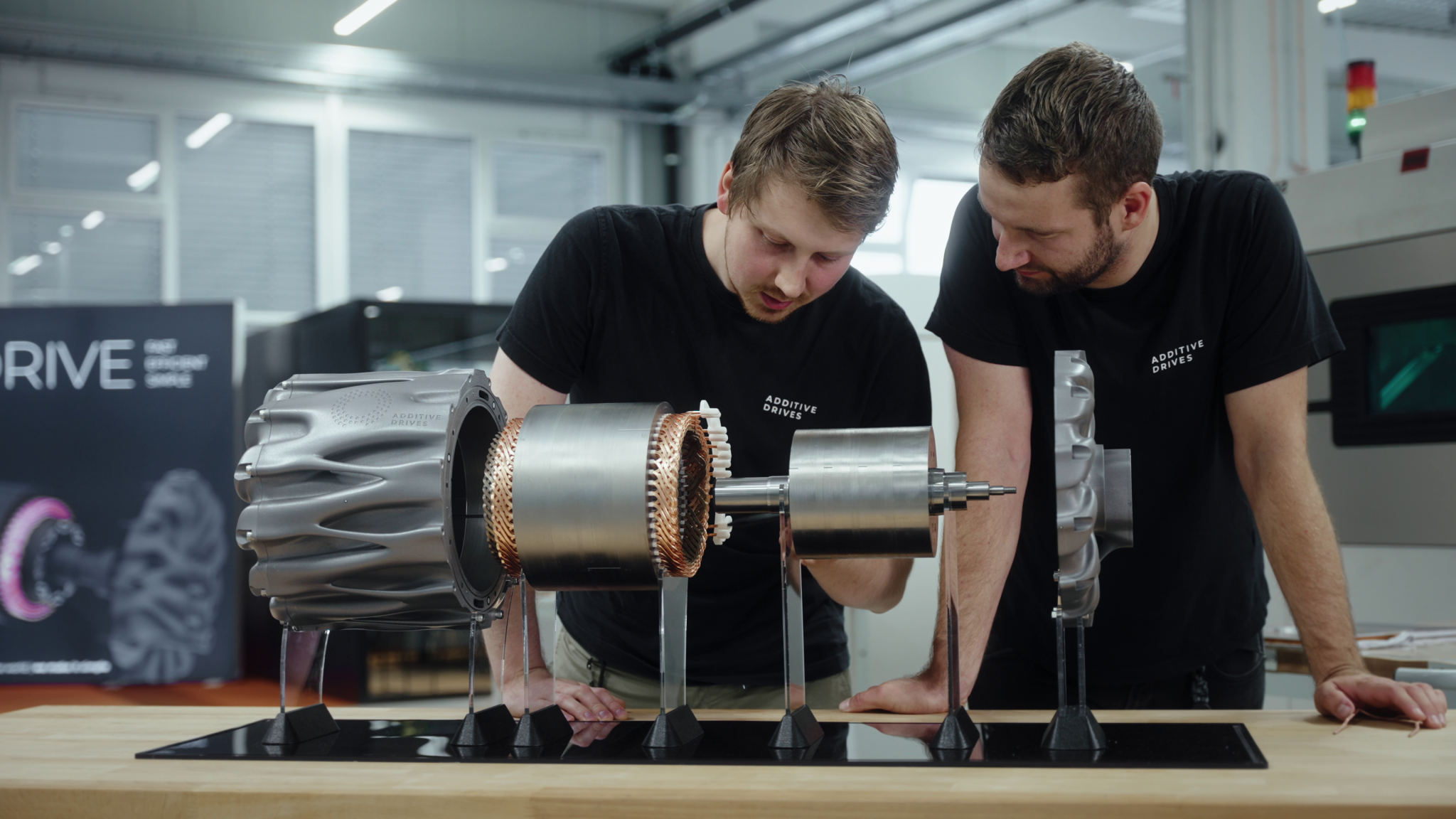

3D scanning and the future of electric motors

Based in Dresden, Germany, Additive Drives is on a mission to simplify electrification. The founders recognized the inefficiency of most electric motors on the market and set out to radically improve electric motor efficiency and power density, not only in automotive but also across aviation, agriculture, and industrial applications.

Scanning small parts with GOM Scan 1 and ATOS Q

From plastics to electronics and consumer goods, small parts are everywhere. Their geometries range from simple to complex with fine structures and tiny holes, each with specific measurement requirements. With the 3D scanners GOM Scan 1 and ATOS Q, scanning small parts is easy.

Unlocking SPAD technology for advanced imaging applications in microscopy and beyond

In early July, Carl Zeiss Microscopy GmbH has acquired all equity shares of Pi Imaging Technology SA, based in Lausanne, Switzerland. Pi Imaging Technology SA now operates as "Pi Imaging Technology SA – a ZEISS company". The Lausanne location with all employees will be retained.

ZEN core now available for all ZEISS scanning electron microscopes

ZEISS now offers its highly flexible and efficient software suite ZEN core for all ZEISS scanning electron microscopes (SEMs), including focused ion beam scanning electron microscopes (FIB-SEMs).

ZEISS presents OMNIA GC 220-180: Large-scale automated X-ray inspection

ZEISS is an internationally leading technology company in the optics and optoelectronics industry. The ZEISS Group generated annual revenue totaling around 11 billion euros in its four segments Industrial Quality & Research, Medical Technology, Consumer Markets and Semiconductor Manufacturing Technology

Advancements in Industrial X-Ray Computed Tomography

Implementing X-Ray CT technology provides a pathway to increased efficiency by overcoming production bottlenecks, addressing issues related to a shortage of skilled labor, and navigating supply chain challenges.

ZEISS enters the aerospace market with a new dedicated Field of Business: AEROSPACE

With the launch of its new AEROSPACE Field of Business, ZEISS is strengthening its strategic focus on high-growth future markets. In addition to the existing areas "Automotive & Consumer" and "Industrial Solutions & Research," AEROSPACE becomes the third Field of Business within ZEISS Microoptics – with a clear focus on micro-optical innovations for the aerospace sector.

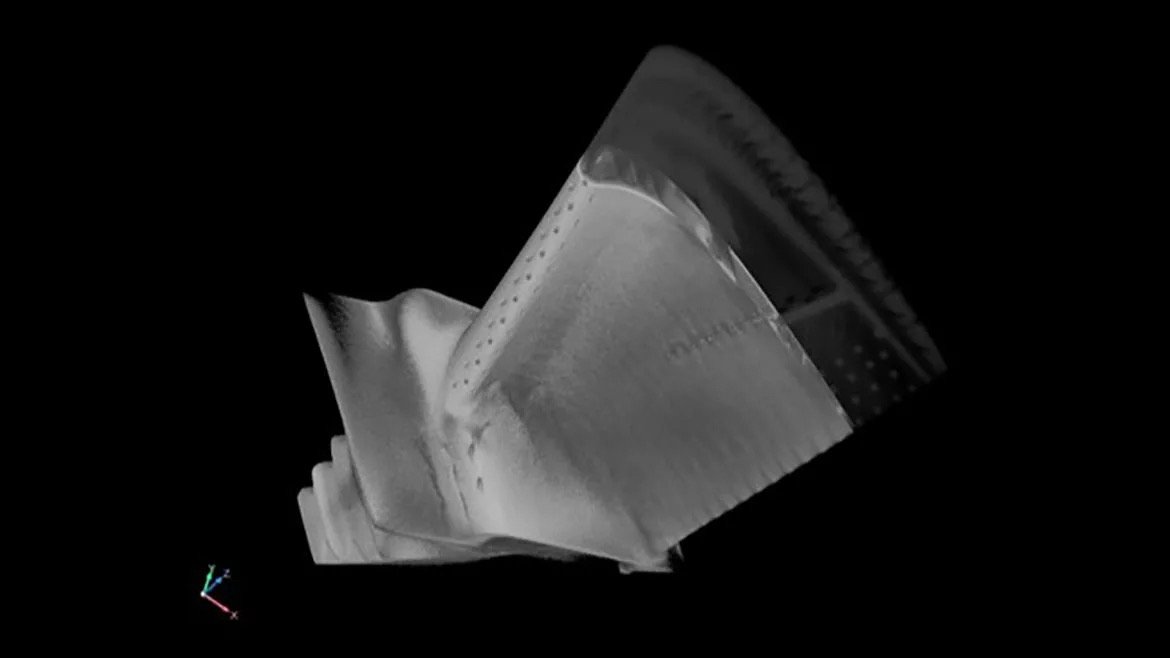

Starrag forms part of the ZEISS PRISMO fortis CMM pilot project

Starrag is known for developing manufacturing solutions for manufacturers within the aerospace industry. To help shorten the measurement times of turbine blades, the company agreed to participate in the ZEISS PRISMO fortis CMM pilot project.

ZEISS introduces ScanPort, a new dimension in semi-automated 3D metrology

With ZEISS ScanPort, ZEISS presents an innovative, powerful solution in optical 3D metrology that combines accuracy, flexibility, and ease of use in a compact system. This new semi-automated system is designed for users who require reliable metrology results - without the need for extensive training or complex setups.

How One Company Turned the Skilled Labor Shortage Into an Opportunity

Founded in 1988, Trace Die Cast (Trace) produces aluminum high-pressure die castings, primarily supplying tier-one and tier-two automotive OEMs. Its campus in Bowling Green, KY, houses machining and assembly operations and 44 diecast machines, making it one of the largest die casters in North America.

Speed meets precision for high-density components – ZEISS METROTOM 800 320 kV

ZEISS is an internationally leading technology enterprise operating in the fields of optics and optoelectronics. In the previous fiscal year, the ZEISS Group generated annual revenue around 11 billion euros in its four segments Semiconductor Manufacturing Technology, Industrial Quality & Research, Medical Technology and Consumer Markets (30 September 2024).

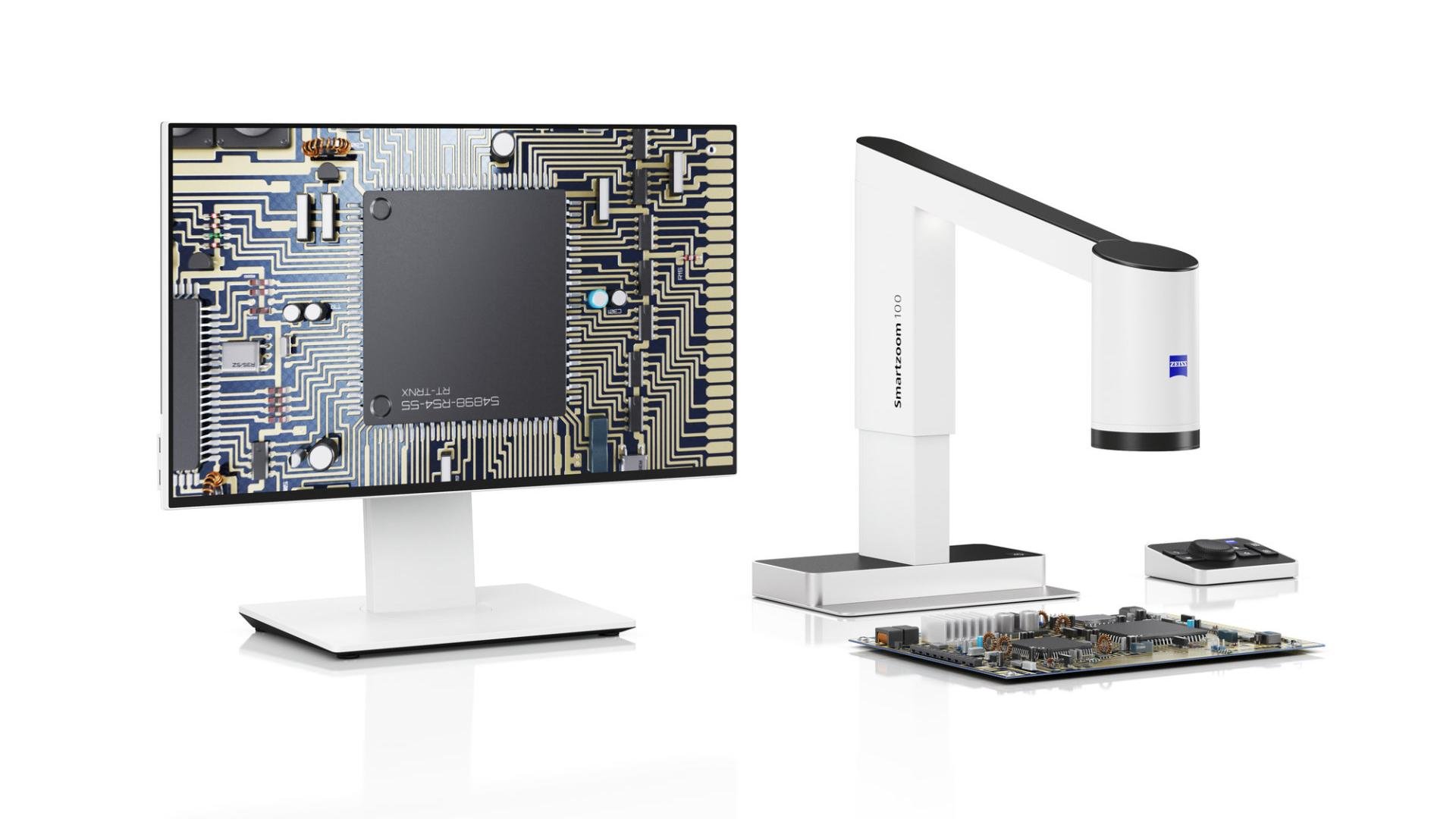

ZEISS introduces the new Smartzoom 100: The future of digital microscopy for efficient optical inspections.

ZEISS presents the new ZEISS Smartzoom 100, an innovative digital microscope for fast and efficient quality assurance. With this state-of-the-art microscope, companies are setting new standards in optical inspection and failure analysis. The system combines exceptional image quality with a user-friendly interface, making it the ideal solution for industrial microscopy.

ZEISS and tesa establish strategic partnership to advance large-scale holographic technology

Technology leaders ZEISS and tesa are joining forces to bring holography to industrial scale. The two companies have signed a strategic partnership agreement to drive the serial replication of large-format, holographically functionalized films – with a focus on transparent display applications in automotive windshields.

ZEISS unveils AI-powered Research Data Platform; collaboration with Boehringer Ingelheim champions the future of personalized eye care

ZEISS demonstrates a new standard for the future of ophthalmic research at the Association for Research in Vision and Ophthalmology (ARVO) conference, from May 4 – 8, including the introduction of the new ZEISS Research Data Platform (ZEISS RDP), and a spotlight on the ongoing research collaboration with Boehringer Ingelheim to accelerate personalized, data-driven treatment approaches in ophthalmology.