You have choices, make the right choice

ZEISS celebrates 100 years of advancing innovation in the U.S.

Today, ZEISS marks 100 years of operation in the U.S., helping Americans improve lives and reach profound achievements by applying the company’s innovative technologies to research, healthcare, manufacturing and more

Understanding ASME B89.7.2: Dimensional Measurement Planning in Precision Metrology

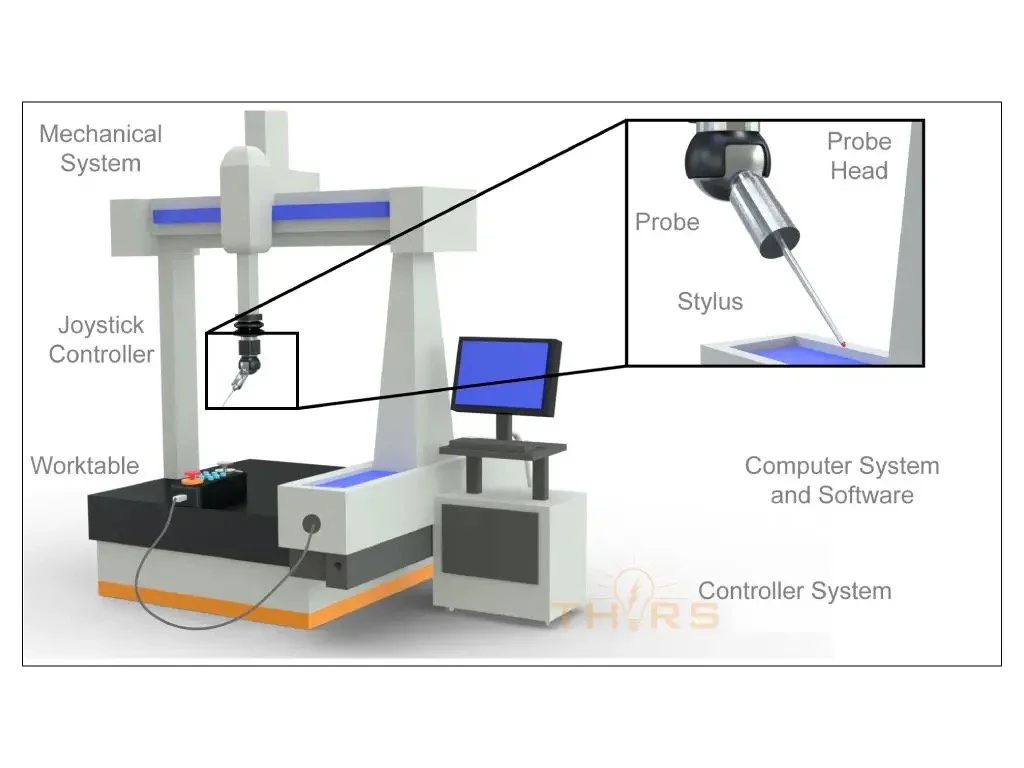

In the field of precision metrology, ensuring the accuracy and reliability of dimensional measurements is paramount, particularly when using advanced tools like Coordinate Measuring Machines (CMMs).

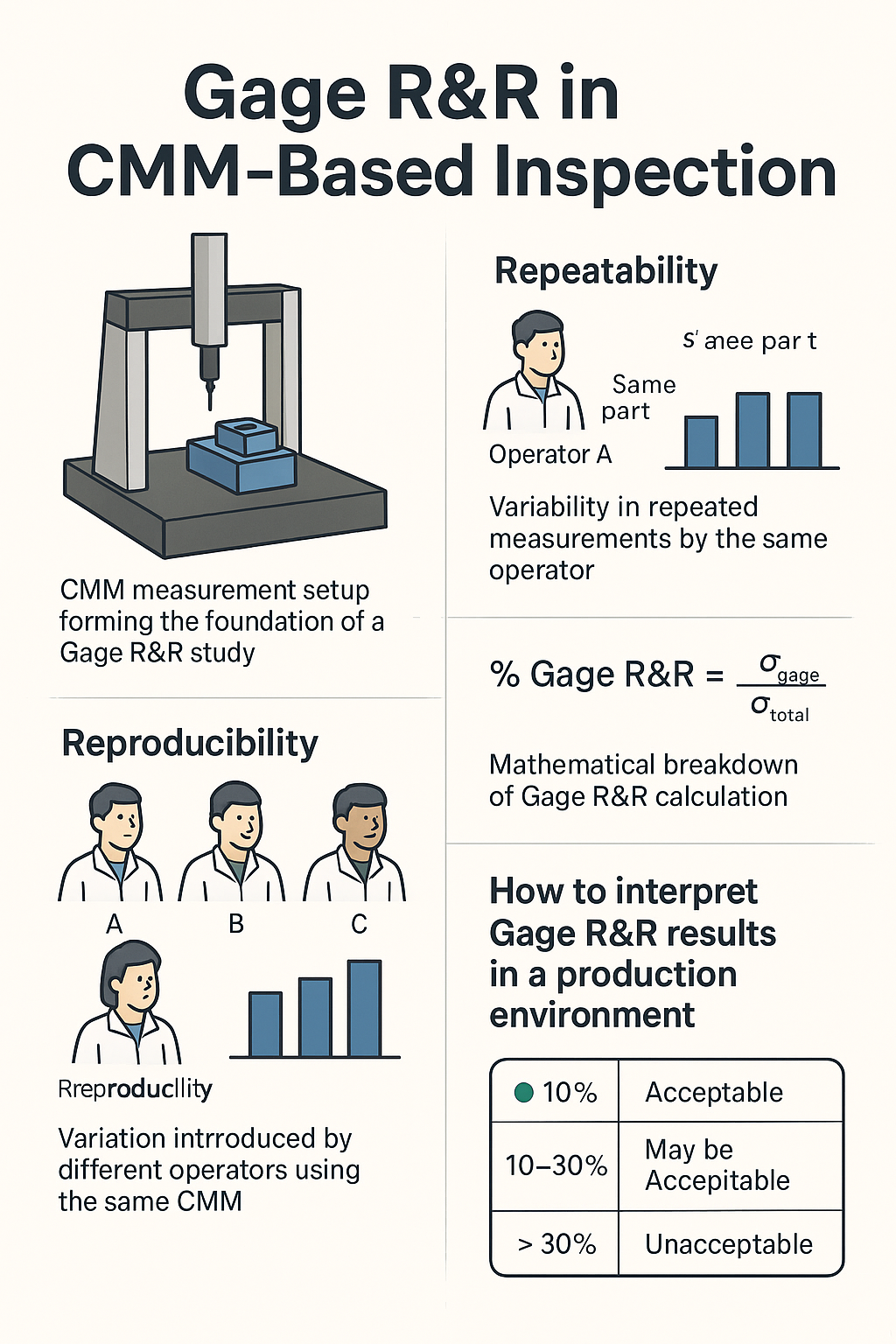

Understanding Gage R&R in CMM-Based Inspection: A Detailed Guide

Gage Repeatability and Reproducibility (Gage R&R) is a vital tool in understanding the reliability of measurement systems, especially in high-precision environments where Coordinate Measuring Machines (CMMs) are used. This analysis quantifies the variation introduced by the CMM, the operators, and the measurement process itself. By examining both repeatability and reproducibility, manufacturers can determine if their CMM-based inspections are trustworthy enough to make critical quality decisions. This guide explains how to conduct a Gage R&R study, interpret the results, and apply key formulas to evaluate your system’s performance.