You have choices, make the right choice

New Benchmarks in Quality Inspection and Data Analysis

ZEISS Industrial Quality Solutions (ZEISS IQS) announces the latest software updates for ZEISS INSPECT and ZEISS PiWeb, addressing the growing challenges of industrial quality control. By providing holistic solutions ZEISS IQS enables end-to-end inspection processes and streamlined workflows.

Micro accuracy for macro volumes

At its Neuenburg site, Nemera relies on Mitutoyo’s measurement technology and a new high-resolution CT system from RX Solutions to ensure absolute precision in injection-moulded medical components — from micro parts just 2–4 mm in diameter to complex dispensers, inhalers and pens.

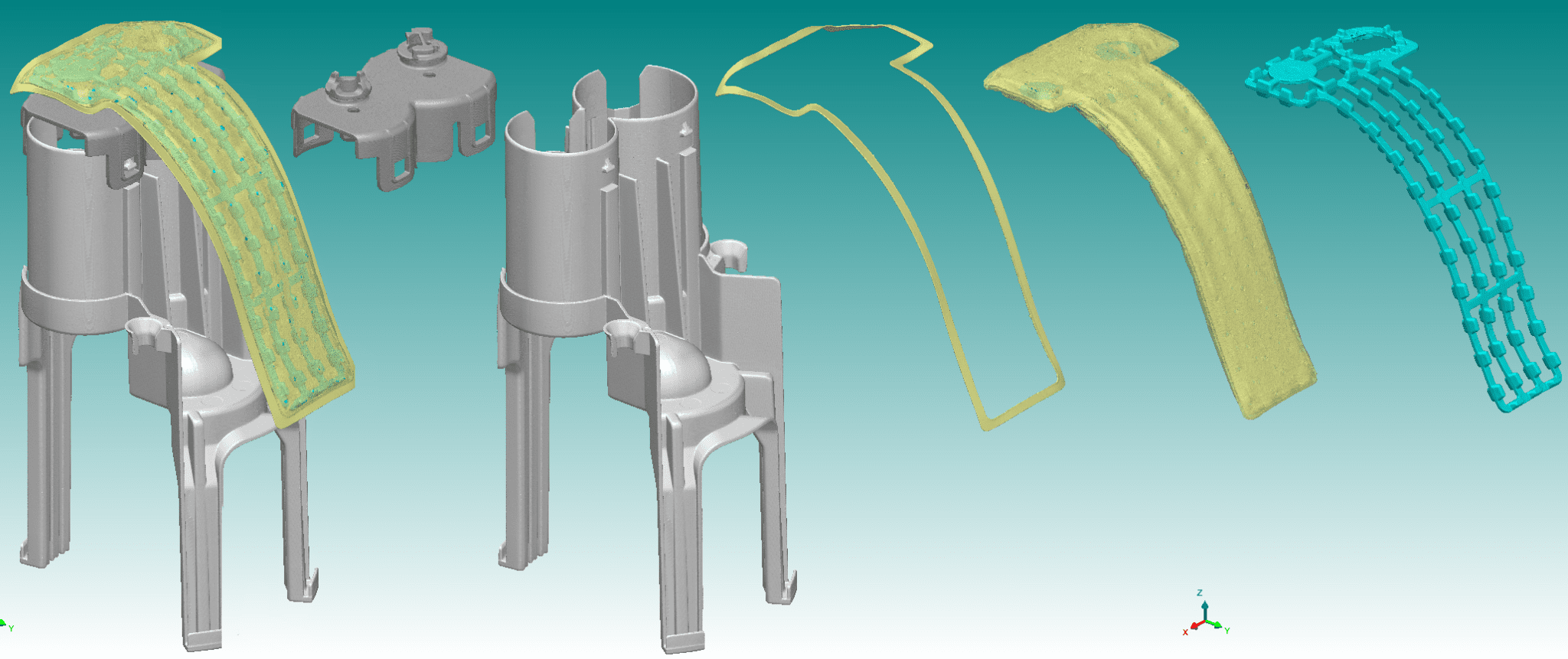

LK Metrology expands into industrial CT by acquiring ProCon X-Ray

Through this acquisition, LK Metrology can now offer its customers an even wider range of products for inspection and measurement from a single source, from traditional CMMs, portable measuring arms and laser scanners to high-resolution X-ray equipment and CT analysis.

Inspecting electronic connector housings using CT technology

Identifying internal defects and correct connector pin positions of electronic connector housings is crucial for proper functioning of the final product. The advanced CT technology of ZEISS METROTOM 1 is the perfect fit to get deep insights of your electronic parts, allowing for quick and intuitive evaluation and improvement of production processes.

Advancements in Industrial X-Ray Computed Tomography

Implementing X-Ray CT technology provides a pathway to increased efficiency by overcoming production bottlenecks, addressing issues related to a shortage of skilled labor, and navigating supply chain challenges.

Are your 3D printed parts as error-free as you think they are?

When working with 3D printed parts, material integrity is of the utmost importance. Imperfections such as voids in the material, delamination and changes in density are critical facets of the additive process to manage.

3D Scanning and Model-Based Definition: A New Look at GD&T

The increasing quality and accessibility of 3D scanning tools, particularly computed tomography, are giving quality control experts much more information about the parts they look at, experts say.

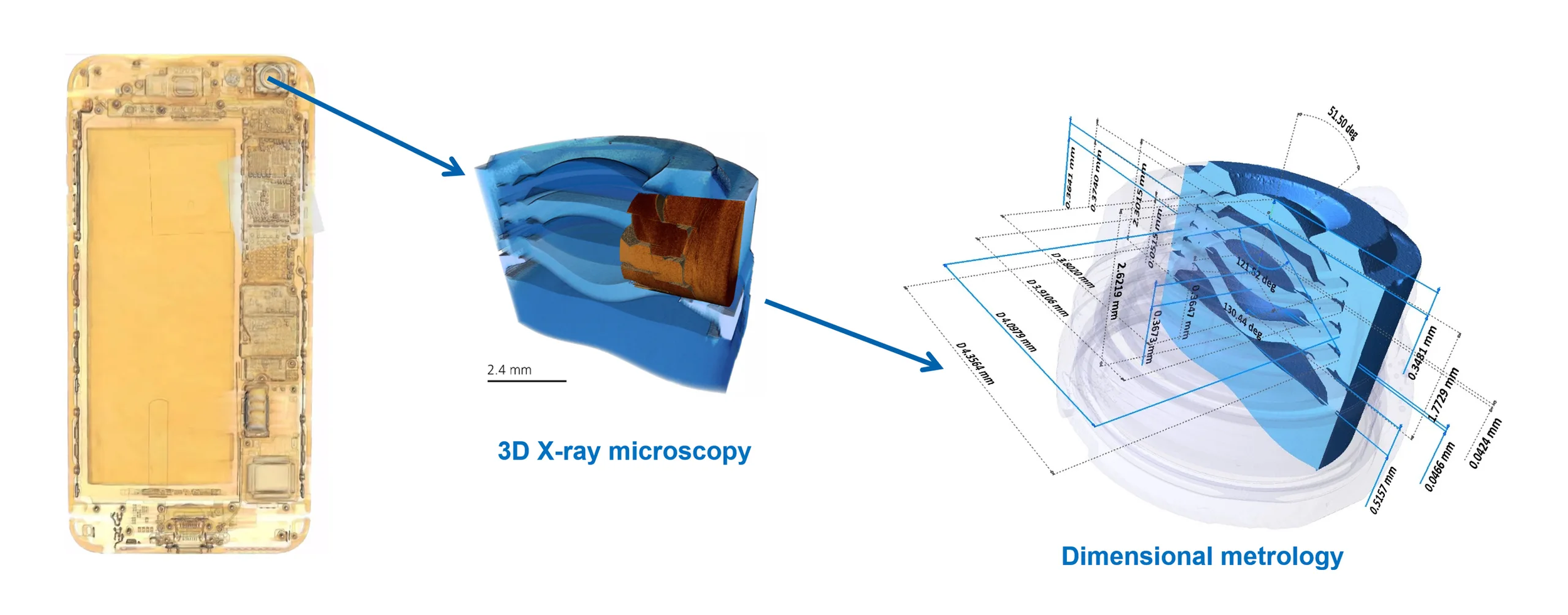

Dimensional Measurements with 3D X-ray Microscopy

The miniaturization and integration of components in small devices, with feature sizes on the order of 10 mm or smaller, is creating an increasing demand for high-resolution metrology in the industry of manufactured and assembled devices.

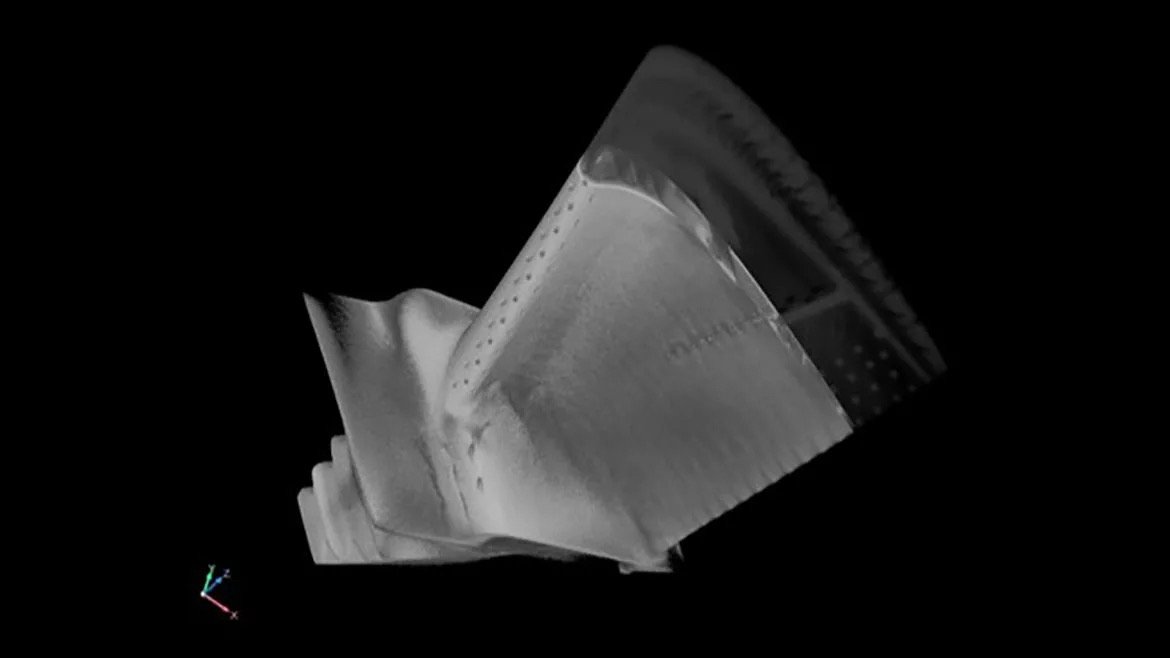

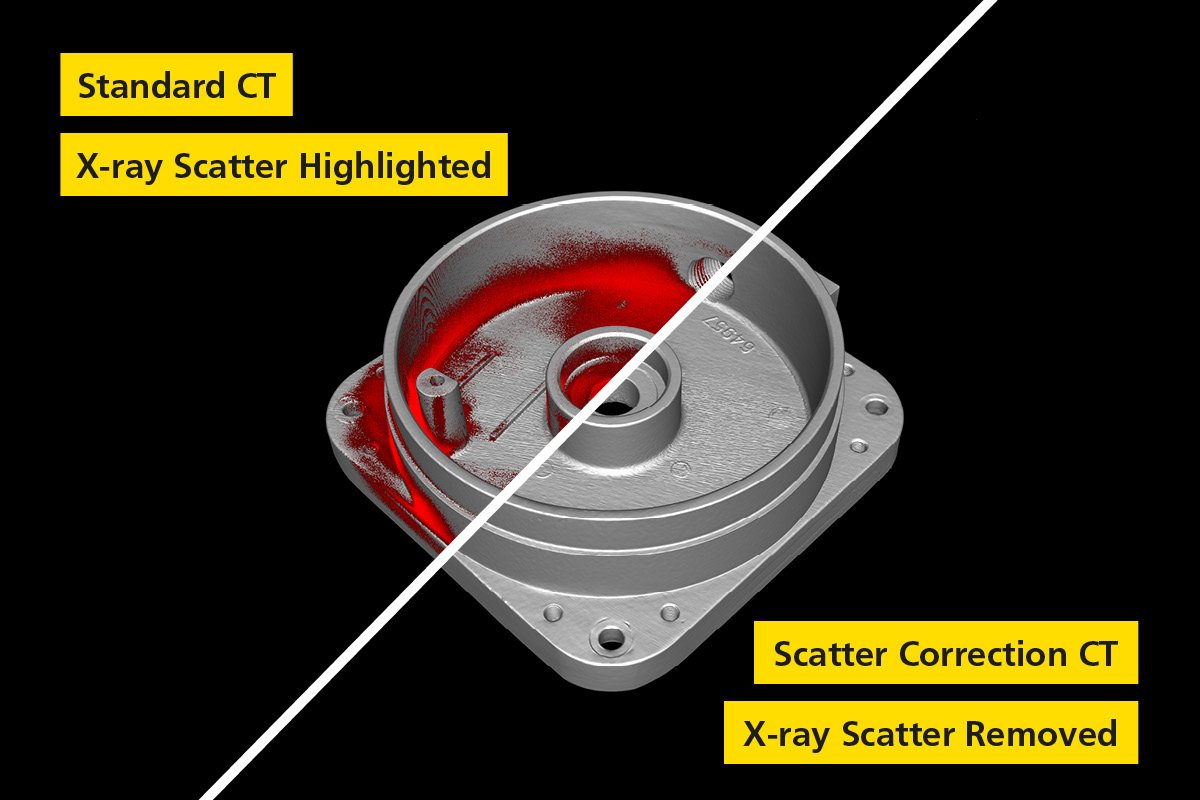

Nikon’s Scatter Correction CT addresses X-ray scatter artifacts in industrial CT scanning

Nikon has announced the launch of Scatter Correction CT, a software solution that enhances image quality and measurement accuracy in industrial computed tomography (CT) scanning by correcting scatter artifacts.

Nikon’s Large-Envelope X-Ray CT System Installed in Hyundai Motor North America’s New Safety, Investigation Laboratory

Nikon Metrology, Inc, and Hyundai Motor North America announced that Hyundai has purchased and installed Nikon’s X-ray computed tomography (CT) system. This represents a significant investment in the success of Hyundai’s newly opened $51.4 million Safety Test and Investigation Laboratory (STIL) in Superior Township, MI.