Maximum precision in machining production

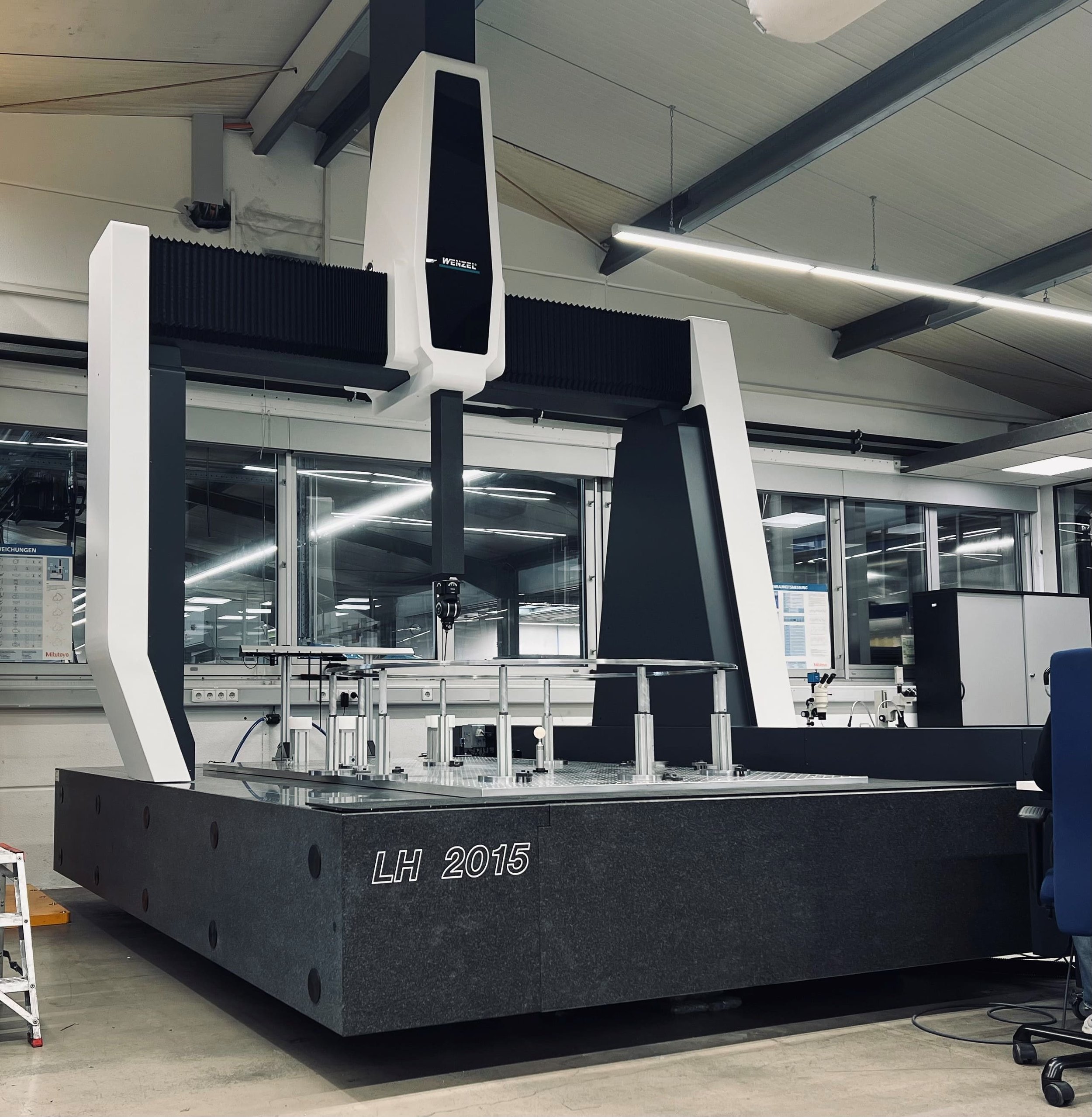

The powerful LH 2015 CMM with WM | Quartis software and the REVO in use at BARTH.

Quality Made in Germany

BARTH Präzisionstechnik GmbH is a reliable partner for high-precision parts in machining production processes. With a broad spectrum from 5 to 2,500 mm and from 5 grams to over 2 tons, the company supplies globally active customers in energy technology, BIM / construction digitization, plant construction and mechanical engineering. The company philosophy is based on maximum precision, a zero-defect mentality and absolute adherence to deadlines.

In keeping with this tradition of continuous quality optimization, the Binzwang-based company opted for the LH 2015 coordinate measuring machine from WENZEL. The powerful LH 2015 gantry measuring machine, equipped with WM | Quartis software and the REVO 5-axis multi-sensor probe system from Renishaw, offers a wide range of measuring options.

Perfect combination of measuring machine, sensors, software and service

The CMMs in the LH series are characterized by extremely precise measuring results and high measuring speeds. LH gantry measuring machines are among the most frequently used coordinate measuring machines on the market. The robust construction made of natural granite ensures durability and the highest quality.

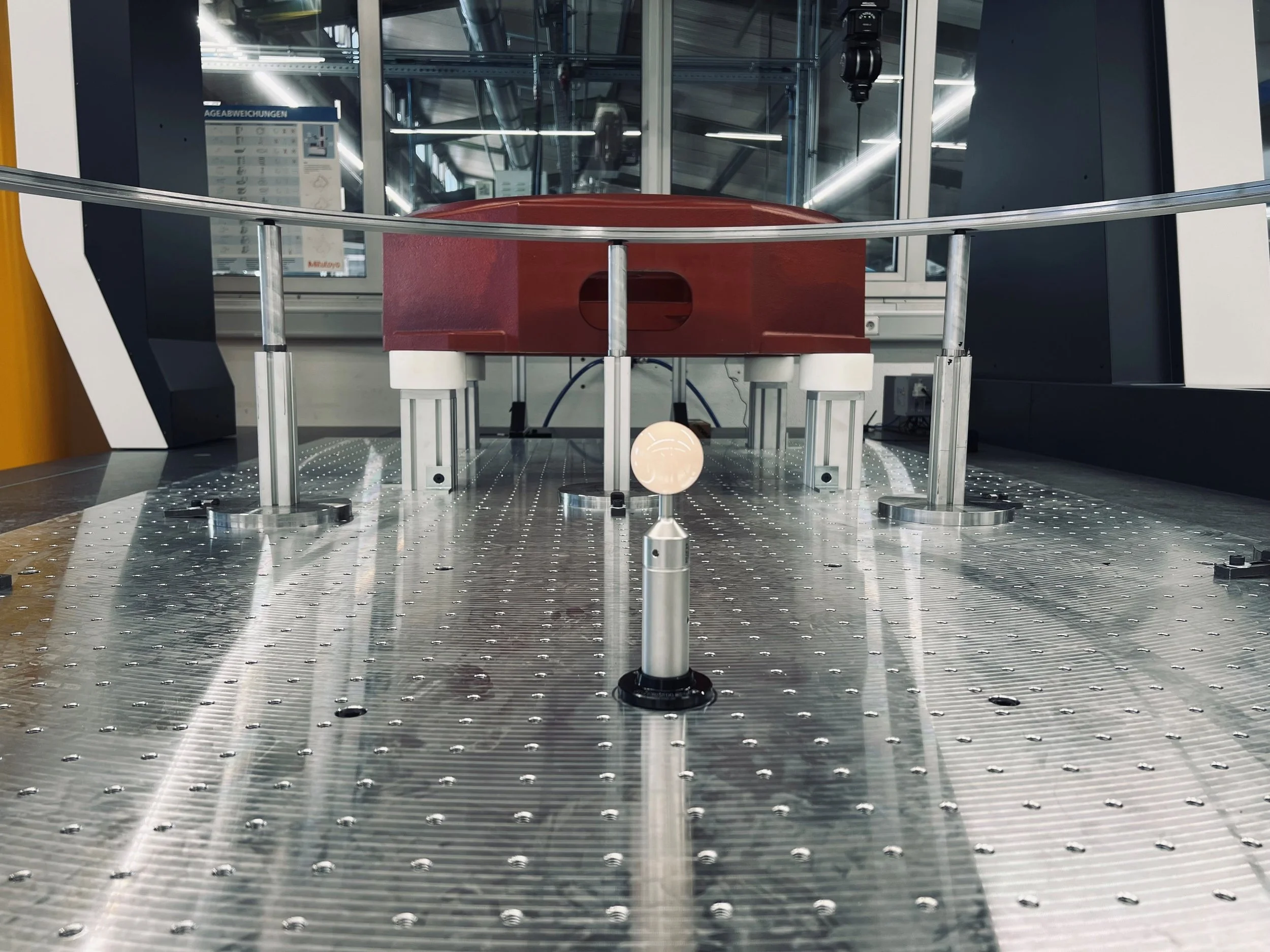

The REVO 5-axis multi-sensor probe system offers a unique combination of contact measurement and scanning, which enables fast and precise measurement of even complex components. Due to its high flexibility and accuracy, the combination of the REVO with the LH 2015 opens up considerable advantages and a wide range of possible applications.

The WM | Quartis software forms the heart of the measurement solution and enables measurement data to be precisely recorded, analysed and visualized. Thanks to its intuitive user interface and versatile functions, the tried-and-tested measurement software is an indispensable tool for quality control.

The professional team at WENZEL supported BARTH with the integration of the LH 2015, resulting in a smooth commissioning. The machine enables BARTH to further optimize its production processes and deliver first-class products to its customers.

The company owners, of whom three generations of the Barth family are currently actively involved in the business, are unanimous:

Manufactured by a German family business in Germany, for use in a German family business to handle high-precision measuring tasks. This measuring machine is not only sustainable for our company, but also pioneering for future generations.

About BARTH Präzisionstechnik GmbH

Precision is not just a goal for BARTH Präzisionstechnik GmbH, it is the foundation of its success. The company values reflect its commitment to the highest standards and form the basis for successful cooperation with employees, customers and business partners. As a family business, BARTH relies on innovative strength, a focus on quality and flexibility in order to meet the constantly changing requirements of its customers. Its clear commitment to maximum precision and adherence to deadlines underlines its reputation as a leading service provider in European industry.