3D Scanning or Tactile Probing?

- all about data

An Article by Ray Xing, President of Xpert 3D Metrology

3D scanning technologies have been rapidly developing in the last 10 years and widely used in manufacturing industries for Metrology purposes. Although people get used to seeing various scanning systems and most time have good understanding on what this technology can bring to you, many common questions still remain such as “should I choose a 3D scanner or a CMM?”, “can I use the 3D scanner to totally replace my CMM?”, etc.

I have been extensively involved in 3D scanning demonstrations, project/application supporting and training for a good 10 years and I can compile a list of no more than thirty questions that are commonly asked during those activities.

As mentioned earlier, one common question is: how do I decide whether I go with a 3D scanning system (stand alone, not including the laser scanner mounted on CMM) or a conventional CMM (including the one with scanning probing)? There are many criteria that can help you decide but this article is focused on one thing – the data set.

If you’ve been keeping an eye on 3D scanning, then you must know the term “digital twin”. All 3D scanning processes (e.g. laser scan, blue light scan, CT scan, etc.) create the same result: a digital copy of the object that it has scanned, called “digital twin”. I call this “data acquisition”, which sets the very basic difference from CMM.

This image shows a very typical CMM data set from probing:

This image shows a very typical data set from 3D scanning (digital twin):

Often many people think it’s a CAD model, but it’s actually a set of point cloud from 3D scanning (in this case, by using ZEISS ATOS Q). But then there will be right away a question: can you convert this into a CAD model? Which is a whole different topic for near future .

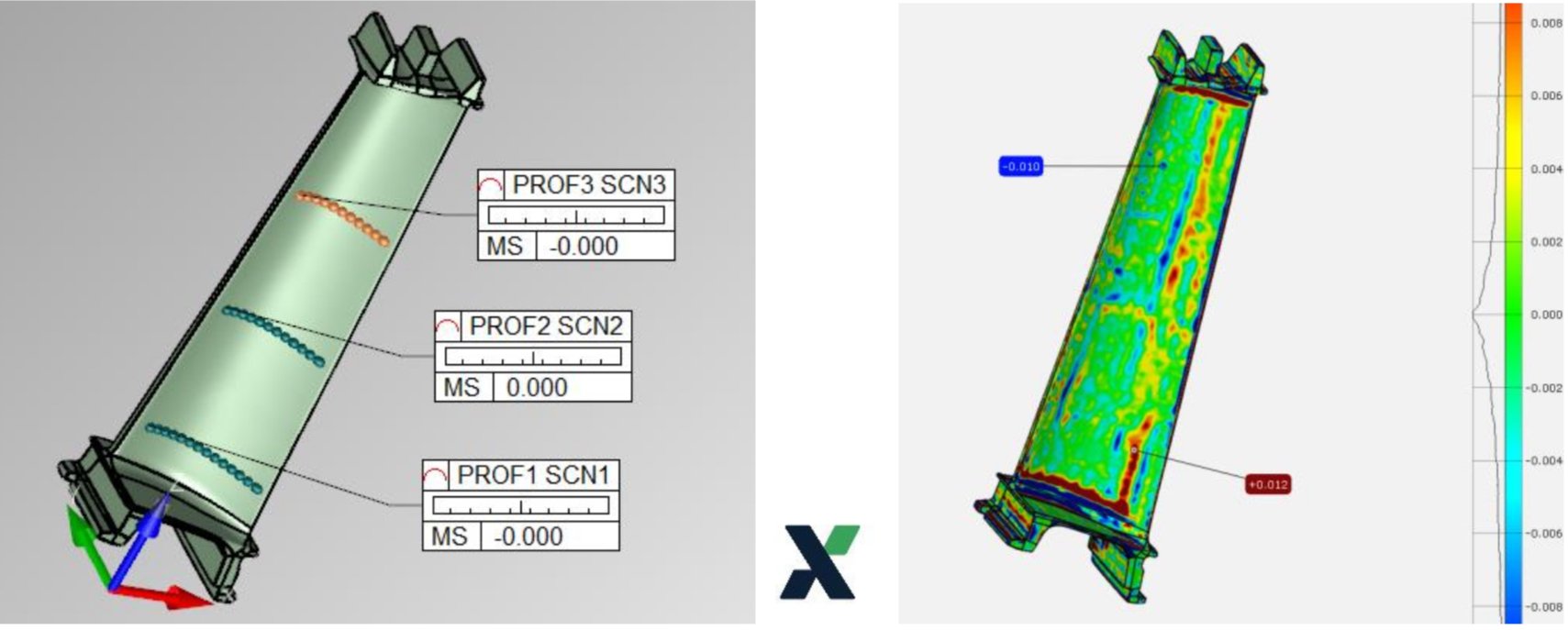

So it’s very obvious that 3D scanning creates a totally different data set than conventional tactile probing (even it’s scanning like SP25M). Because of this, the dimensional results you can extract will be very different:

Most people would agree that the colour map (or heat map) is a much better presentation not only because it looks “pretty” but also because it provides much more valuable information and more comprehensive information, which is very true. However, I’d like to point out that it really depends on what your requirements are, the old school results might be just sufficient.

Again, my purpose is to point out that the very fundamental differences between 3D scanning and conventional probing is the data set, which I think is a good starting point to understand better between these 2 technologies. Even just surrounding this basic point, there’re more questions to ask:

➢ How is the accuracy of 3D scanning data?

➢ How fast is the 3D scanning process?

➢ What’s the resolution of this data set?

➢ How large is the data set?

I’ll continue to contribute some articles focused on 3D scanning technologies. But if you can’t wait and have many questions that need to be answered directly, please feel free to reach out to me: ray@xpert3d.ca or use our contact page: Contact Xpert | Xpert3D Metrology

This article is from Ray Xing - use the QR code to contact him for more information