How To: Operation Planner

Do you manufacture parts in distinct operations? Is the part also inspected after / during each of these distinct manufacturing operations? Are you creating unique CMM-Manager programs for each operation? If so, there is a better way

...Meet Operation Planner...

Operation Planner allows user to effectively create sub-programs from one main program. The main benefits include the speed at which sub-program (Operation Plan) is created, and the fact that only one program must be maintained. Imagine the amount of effort required for a Drawing Revision change if you are using multiple programs, with Operation Planner you just change the main program and all Operations Plans automatically update.

Create a complete inspection program in the usual manner. Think First Article or Last Article inspection here... Just create a program that inspects and reports all characteristics on drawing.

Define the Operation Planner Safe Cube. This is a cube in which the probe will move outside in the case that measurement operations are skipped during Operation Plan execution - more on this later.

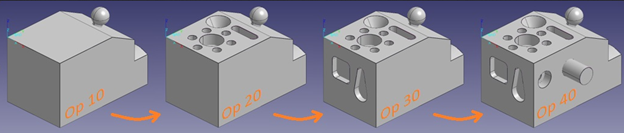

Create Operation Plan by multi-selecting (use Shift or Ctrl keys) Operations from the Program Database, right click and choose Operation Plan. Important - Typically you will choose the first few Operations in Program including the main Alignment. See examples for Op 10 and Op 20 below.

- Select Operations 1-17, right click Operation Plan

- Select Operations 1-10 & 21-38, right click Operation Plan

Now you can run each Operation Plan by clicking Operation Planner button from Ribbon Tab>Program>Operation Planner>Operation Planner. Select the Operation Plan you'd like to run and press Run button.

Also notice the "Keep original paths for consecutive measurement" check-box. When unchecked each measurement operation will include a clearance move (before and after) outside the current Clearance Cube. Checking this box will allow originally planned paths to execute for consecutive program operations, thus maintaining a more efficient probe path. In general, the Clearance Cube is used when any portion of the original program is skipped, thus allowing safe program execution even when tip angle is different from one block of program to the next. In the Operation Plan shown below, the Probe will move outside of Clearance Cube as the program skips from Operation 10 to Operation 21.

Now you have one CMM-Manager program that allows running 5 different part configurations.

Complete Part - Run the program as usual.

2. Op 10 - From Operation Plan choose Op 10 and press Run button

3. Op 20 - From Operation Plan choose Op 20 and press Run button

4. Op 30 - From Operation Plan choose Op 30 and press Run button

5. Op 40 - From Operation Plan choose Op 40 and press Run button

Do you need to provide a simple User Interface for Shop Floor users to find and Run programs? Check out Shop Floor Launcher. You can even recall Operations Plan from Shop Floor Launcher