When All You Have Is a Hammer: Key Considerations When Evaluating Appropriate Tools for Quality Inspections

A good inspection should balance conformance and efficiency.

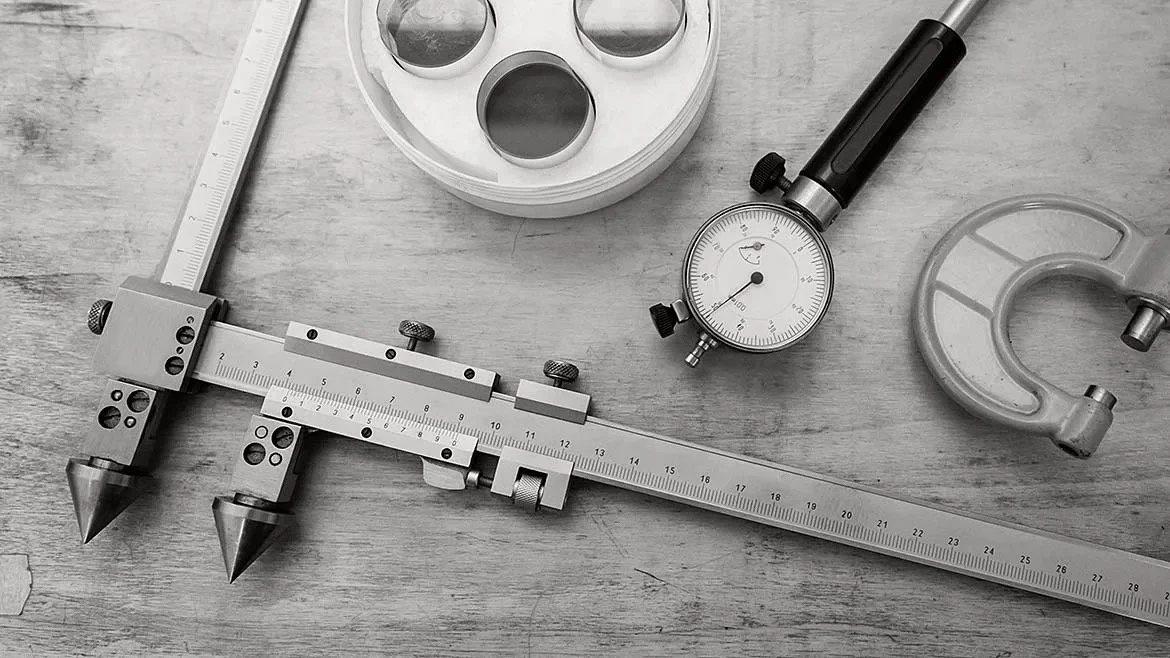

I have often been told that if all you have is a hammer, then everything looks like a nail. I believe this is often proved true in quality inspections. I have worked with many colleagues who often use less than ideal tools to evaluate features. Sometimes they do so out of personal confidence with their chosen instrument over a less familiar alternative, sometimes they make the choice because they don’t know about the existence of more specialized tools, and sometimes they do so out of convenience. It is vitally important that quality inspectors maintain a clear understanding of what tools are available and appropriate for any feature inspection. Most features of size could be measured with any of a half dozen different tools. Deciding which tools to use and, more importantly, which tools not to use is essential to ensuring the accuracy, repeatability, and establishing confidence in your report. In this article I will highlight several key considerations that should be evaluated by any quality personnel before inspecting a part.

Arguably the most important consideration is what type of inspection the tool is designed for. If we are measuring the outer diameter of a cylinder, for example, then an outside micrometer is one of the best tools that could be used. An outside point micrometer, however, would struggle to get an accurate reading on opposite sides of a cylinder. On the other hand, if we were looking to measure material thickness on a curved part, a point micrometer is one of the best tools that could be used while an outside micrometer will produce an erroneously high thickness. There is an almost endless collection of variations on specific tools meant to solve almost any measurement challenge but each variation comes with its own limitations and stipulations on its appropriate usage. Some of these limitations, like we saw above, can be related to the shape of the feature to be measured. Some limitations relate to the type of material. Ultrasonic inspection, for example, can be used to easily measure the thickness of most sheet metal parts, but may struggle to accurately evaluate parts made of mixed media, parts with layers, and parts with voids. Knowing each tool’s strengths and limitations is essential to selecting the best option.

Another important detail to consider is the tolerance of the feature we are measuring when compared with the tolerance of the tool we want to use. This aspect is often described as a gage ratio and is often controlled by the organization’s quality procedures and the customer contracts. Most organizations I have worked with utilize a gage ratio of 4-1 or 10-1; for simplicity’s sake I will assume that we are working with a 4-1 ratio. If we are measuring a part that has a tolerance of ±0.030”, then the tool we are using should have an uncertainty of no more than ±0.0075”. That means most standard metrology tools would be appropriate. If the tolerance for the feature we are evaluating is ±0.005” then we would need to use a tool with an uncertainty of no more than ±0.00125”. This uncertainty requirement would allow most hand tools like calipers and micrometers to be used but may prevent us from using, for example, a relatively large (4.0-meter range) portable coordinate measuring machine (pCMM). A small pCMM, however, should be able to achieve this requirement. If our feature has a tolerance of 0.001” or less then the tool must have an uncertainty of less than 0.00025” which means that we will have to use an extremely precise tool such as a bridge coordinate measuring machine (CMM). In certain cases, when uncertainty must be kept to an absolute minimum, computed tomography (CT) or a laser interferometer may be required. Ensuring that we choose an appropriately accurate and repeatable tool will ensure that our inspections can find any deficiencies present and lends confidence to our credibility as an inspector.

The next critical determination lies in the inspector themselves. Specifically, what level of training and proficiency we have with the tool in question in the application we are using it in comparison with what level of training and proficiency is necessary to use the tool appropriately. Often quality personnel acquire their knowledge and skills through a combination of training, on the job experience, and support from more experienced colleagues. This often leads to differences in the practical abilities of different inspectors and can lead to some inspectors not being able to use the best tool for an inspection due to a lack of knowledge or confidence in their abilities. This factor should both serve as a consideration for what tool is appropriate to use in our current inspections and as a guide for inspectors as to where they can gain the largest advantage in additional training.

We should also consider the type of information we require. Some inspections will require detailed results of every feature, some will be satisfied with a range of values, and some require only a confirmation that the parts conform. Generally, the less information that is required in your inspection, the less complicated an inspection is required. A simple go/no-go gage can ensure conformance without providing numerical results, where using pin gages can quickly identify and quantify the range of values. The more information that is collected, the more confidence we can have in our report but it also increases the length of our inspection and the amount of detail we must provide in the report. A good inspection should balance the pursuits of ensuring conformance and maintaining efficiency.

The final detail to consider is the availability of the ideal tool. Sometimes we have to work with less-than-ideal tools if our company does not have access to the ideal tool or if the ideal tool is not available. In these situations, we must be prepared to understand what tools are acceptable and we must be able to defend our choices to management and customers if they express concerns. These conversations can also allow us the opportunity to present the case for acquiring the ideal tool. A good inspector should always be looking at what deficiencies their inspection tools have so they can readily identify opportunities for improvement when funding becomes available.

Ultimately, the most important tool in any quality lab is the inspector themselves. The knowledge, skills, and abilities of inspectors is essential to all quality functions and those key factors empower inspectors to ensure they are using the right tool at the right time. Through our experience, we gain the insights that allow us to discern when an inspection is a nail requiring a hammer or a screw requiring a screwdriver.