Understanding Filter and Outlier for CMM Application - Part 3

By Mark Boucher, CMM Quarterly

This is the last part in the 3-part series. Here we will cover Linear Features.

Linear Features

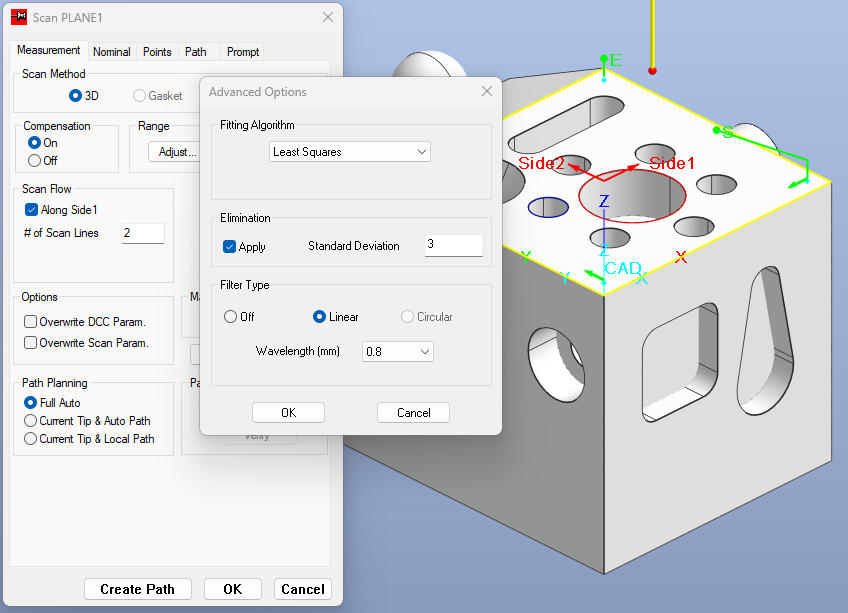

The wavelength filtering must be set for linear features. As discussed before, the higher the value the more smoothing will be applied.

Settings Based on Linear Size

Datum Feature

It is highly recommended that multiple scan lines be used especially when creating a datum feature.

Scan at least 4 lines, 10% away from the edges. The exception would be if the plane is too narrow for 4 scan lines, then scan 2 lines. If the plane is still too narrow, then scan 1 line. A single line must never be used as a primary datum.

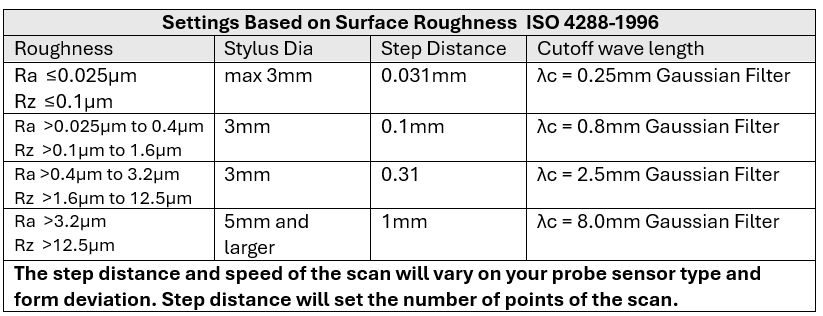

Settings Based on Surface Roughness

Apply Filter

CMM Manager Filtering for Linear Features