You have choices, make the right choice

Education, Metrology and Manufacturing in Sync

Vincennes University, Vincennes, IN, a flagship HTEC (Haas Technology Education Center) and Flying S Inc, Palestine, IL, are an example of education working in lockstep with a real-world industry partner.

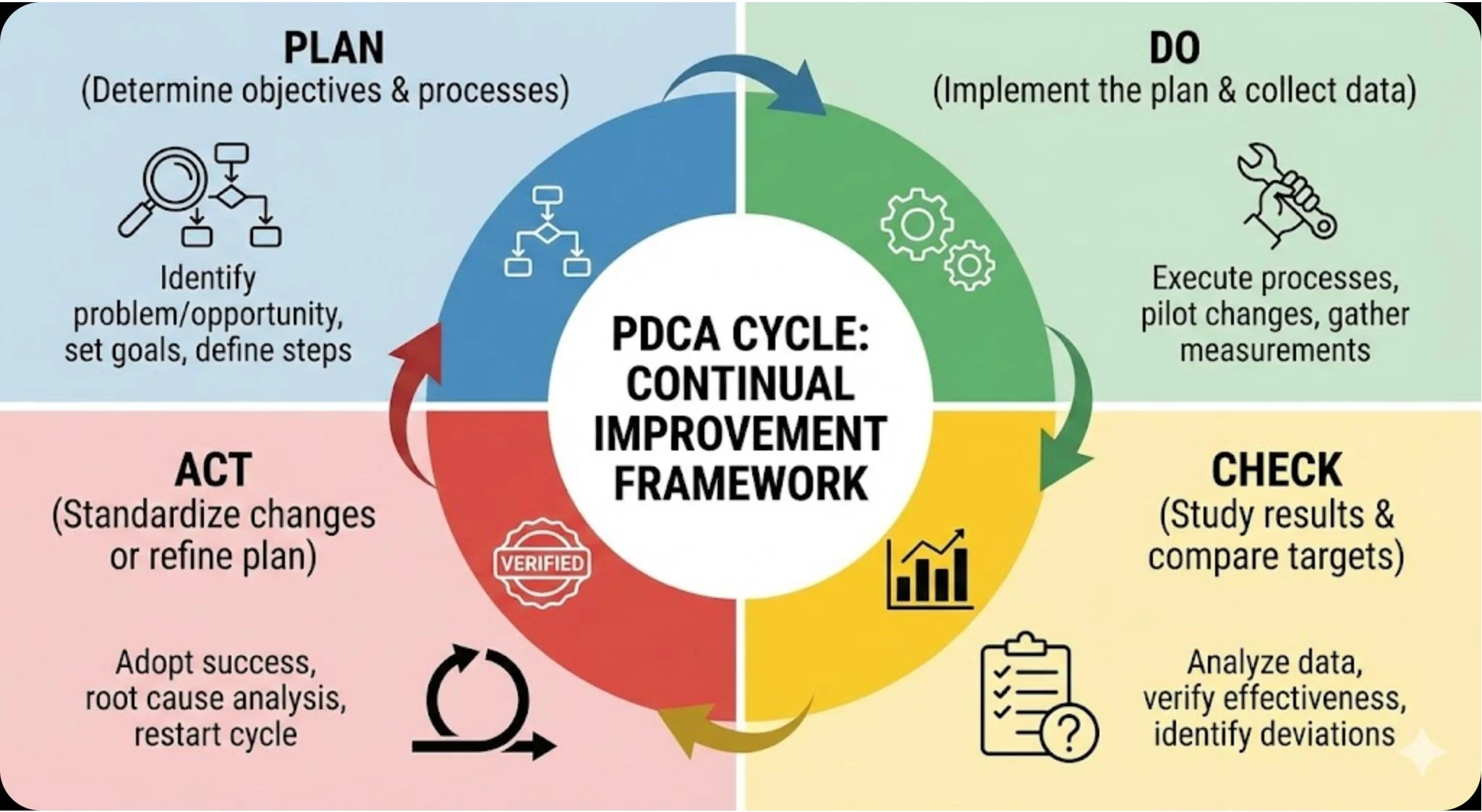

Kaizen Explained in Detail

Kaizen (改善) = Kai (change) + Zen (good) → Change for the better

or more commonly translated as Continual Improvement.

It is both a philosophy and a practical method.

The Engine of Operational Excellence: Mastering Continual Improvement in Manufacturing

In the modern industrial landscape, stagnation is a precursor to obsolescence. The manufacturing sector does not reward the companies that reach a peak and rest; it rewards those that view the peak as a mere waypoint to higher ground. This philosophy is the essence of Continual Improvement (CI).

From Pen and Paper to AI: Transforming Manufacturing

As more supply chain risks like tariffs ripple through operations, outdated systems can no longer adapt to the pace of change required.

ZEISS Opens New Connecticut Quality Excellence Center to Strengthen Northeast Manufacturing

ZEISS Industrial Quality Solutionstoday announced its new Quality Excellence Center in Bloomfield, Connecticut, as part of its continuous expansion of support for U.S. manufacturers. Located at 340 West Newberry Rd., the facility will provide advanced resources for precision metrology, technology demonstrations, and local experts who specialize in helping manufacturers solve industry challenges with innovative solutions.

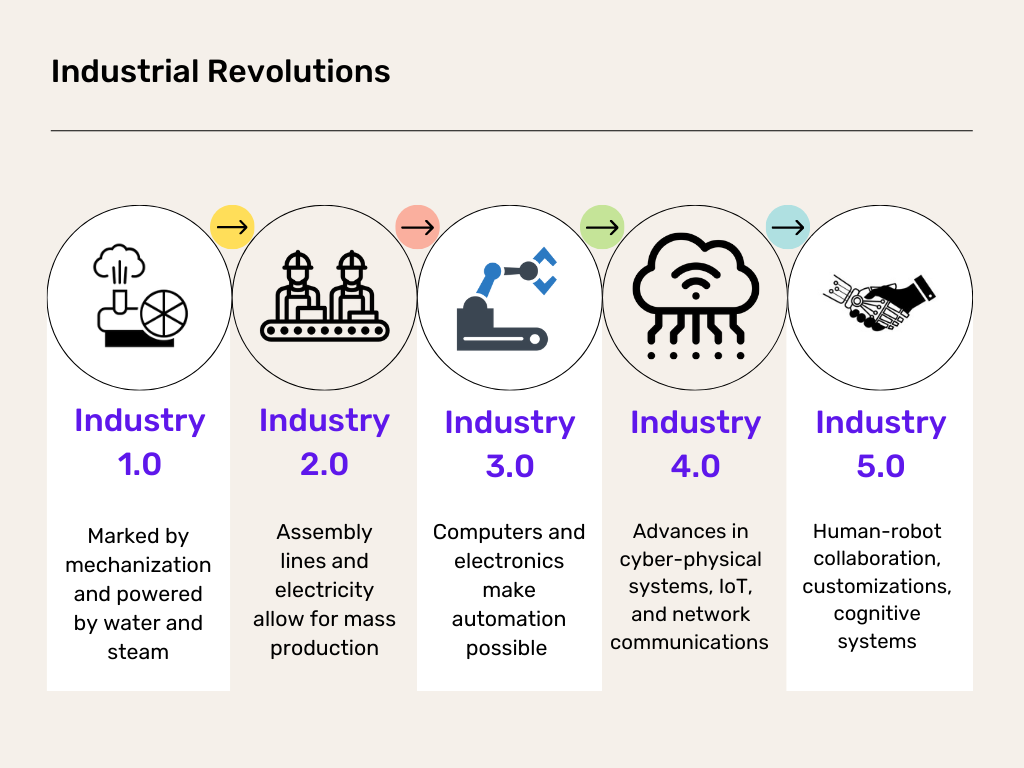

Advancements in Quality 5.0: Pioneering Proactive Excellence in Manufacturing

As manufacturing evolves into the era of Industry 5.0, Quality 5.0 emerges as a transformative paradigm, shifting from reactive to proactive quality management. Building on the digital foundations of Quality 4.0, this next phase emphasizes human-centric approaches, sustainability, and seamless human-AI collaboration to enhance efficiency, reduce defects, and foster resilient production systems.

5 Powerful Ways AI Image Recognition Improves Quality Control in Manufacturing

Quality control in manufacturing is a crucial factor in the success of any industrial operation. It ensures that every product meets quality standards, satisfies customers, complies with regulations, and upholds a positive brand reputation. However, traditional quality control (QC) methods often face challenges such as inconsistency, low throughput, and high operational costs.

Beyond Inspections: The Secret to Building a Quality-Driven Manufacturing Culture

Quality isn’t a department. It’s a mindset. That mindset can mean the difference between thriving and simply surviving. The modern customer demands flawless products, delivered on time, every time. Yet for many manufacturers, quality still feels like an endless game of catch-up – reacting to problems after they happen, throwing resources at rework and trying to patch cracks in the process while the production line keeps moving.

Rethinking Quality: Why Additive Manufacturing Must Grow Up to Move Forward

For years, additive manufacturing (AM) has been synonymous with prototyping. Fast, flexible, and relatively affordable, it allowed engineers and designers to bring ideas to life quickly. Expectations around the technology set are continuing to grow as AM processes edge further and further into the realm of production.

Beyond the Factory Floor: Why Smarter Tools Mean Smarter Quality Control for U.S. Manufacturers

How new tools—including 3D laser scanning and probing devices—can help the industry innovate and adapt in an increasingly competitive (and tariffed) world.

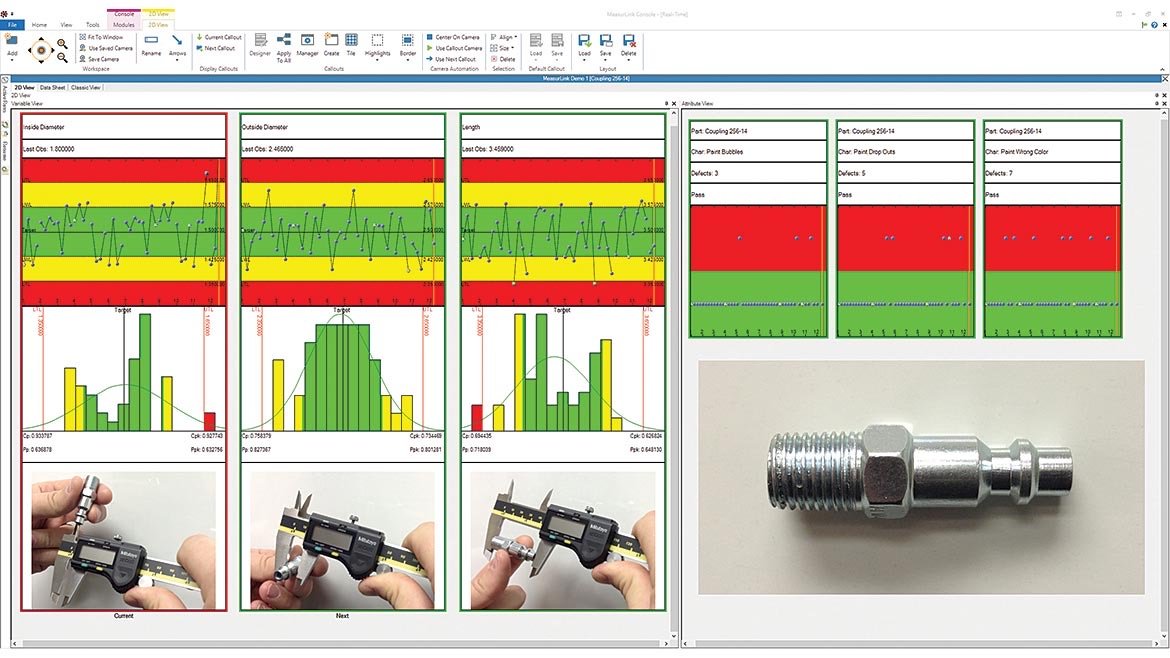

Making Capability Studies Work for You

Capability studies are a routine part of quality work. Teams often calculate indices, document the results and share them to show that a process can meet specifications or satisfy audit requirements. But when applied proactively, capability studies offer insight into how a process is performing and where small changes might bring it into even tighter control.

Leveraging F1 manufacturing technology for the mass automotive industry

Formula 1 (F1) is synonymous with speed, precision, and cutting-edge technology. While glamourous locations and thrilling driver skill capture the imagination, it is the sophisticated manufacturing technology behind these extraordinary machines that makes everything happen as safely as possible.

Beyond the Measurement: How Data Management Software Can Transform Modern Manufacturing

When it comes to measurement data software, it’s easy to think the discussion begins and ends with raw measurement values, but it’s about much more than that. Yet many shops still see “quality data” as nothing more than a list of measurement values. In this article, we will discuss and highlight the many benefits of deploying a higher quality of measurement data software throughout your manufacturing company and show how measurement data software delivers much more than numbers.

Renishaw helps Irish Manufacturing Research (IMR) to advance aerospace optics manufacturing

Renishaw has collaborated with Irish Manufacturing Research (IMR) to support groundbreaking research into additive manufacturing (AM) for novel aerospace materials.

Ensuring Parts Fit, Using Bonus Tolerance to Your Advantage

Designers can use ASME Geometric Dimensioning and Tolerancing (GD&T), an internationally recognized symbolic language, to describe the acceptable limits of part feature variance.

Digital Twins: Elevating Manufacturing Standards and Reducing Errors

Digital twins, once a concept reserved for speculative fiction, now stand at the forefront of modern manufacturing and quality control. These virtual replicas of physical assets that range from individual machines to entire production lines, enable organizations to simulate, test, and optimize processes before making real-world changes.

How One Company Turned the Skilled Labor Shortage Into an Opportunity

Founded in 1988, Trace Die Cast (Trace) produces aluminum high-pressure die castings, primarily supplying tier-one and tier-two automotive OEMs. Its campus in Bowling Green, KY, houses machining and assembly operations and 44 diecast machines, making it one of the largest die casters in North America.

The Death of Tactile Quality Control

Not long ago, quality assurance in aerospace was a narrow, hands-on process. Inspectors would physically verify installations: feeling the torque on bolts, tracing defects to their origin, and leaving behind ink-smudged paperwork as evidence of accountability. It was tactile, deliberate, and sometimes slower—but it worked.

How Quality Engineers Use Data to Address Root Causes in Manufacturing

Quality engineers help manufacturing teams identify and solve the underlying causes of production problems through data analysis.

Manufacturing quality – the result of a whole of business approach

Manufacturing quality products are not made by accident. Quality processes are needed to make them. These quality processes are not confined to the shop floor.

Being in the business of manufacturing, it’s fair to say the overwhelming focus for improvement in our sector tends to rest on production cycles. Placing the focus on how to design and make the best products makes sense. But how often do you hear industry commentators, peers or colleagues talking about the operational side of business?