You have choices, make the right choice

Understanding ISO 10360 Standards for Coordinate Measuring Machines

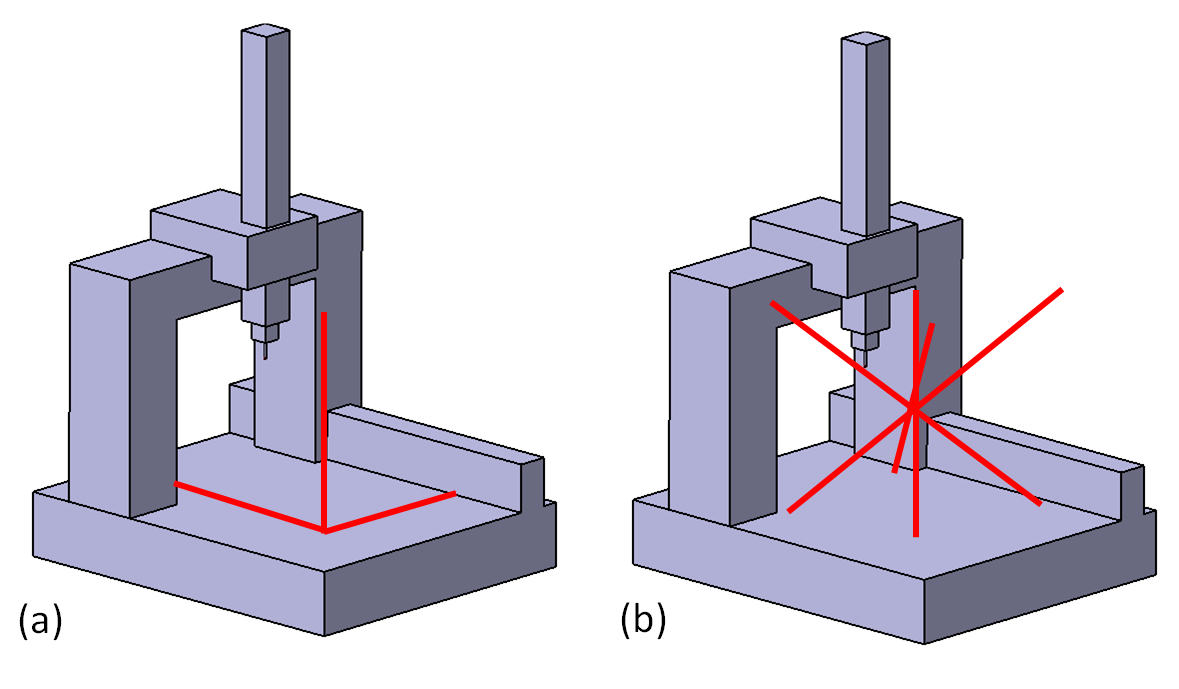

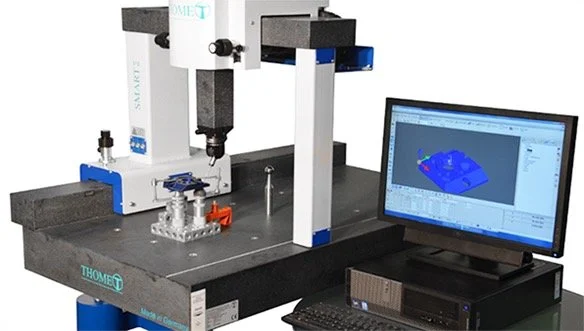

The ISO 10360 series is an international set of standards developed by the International Organization for Standardization (ISO) to specify acceptance and reverification tests for Coordinate Measuring Machines (CMMs).

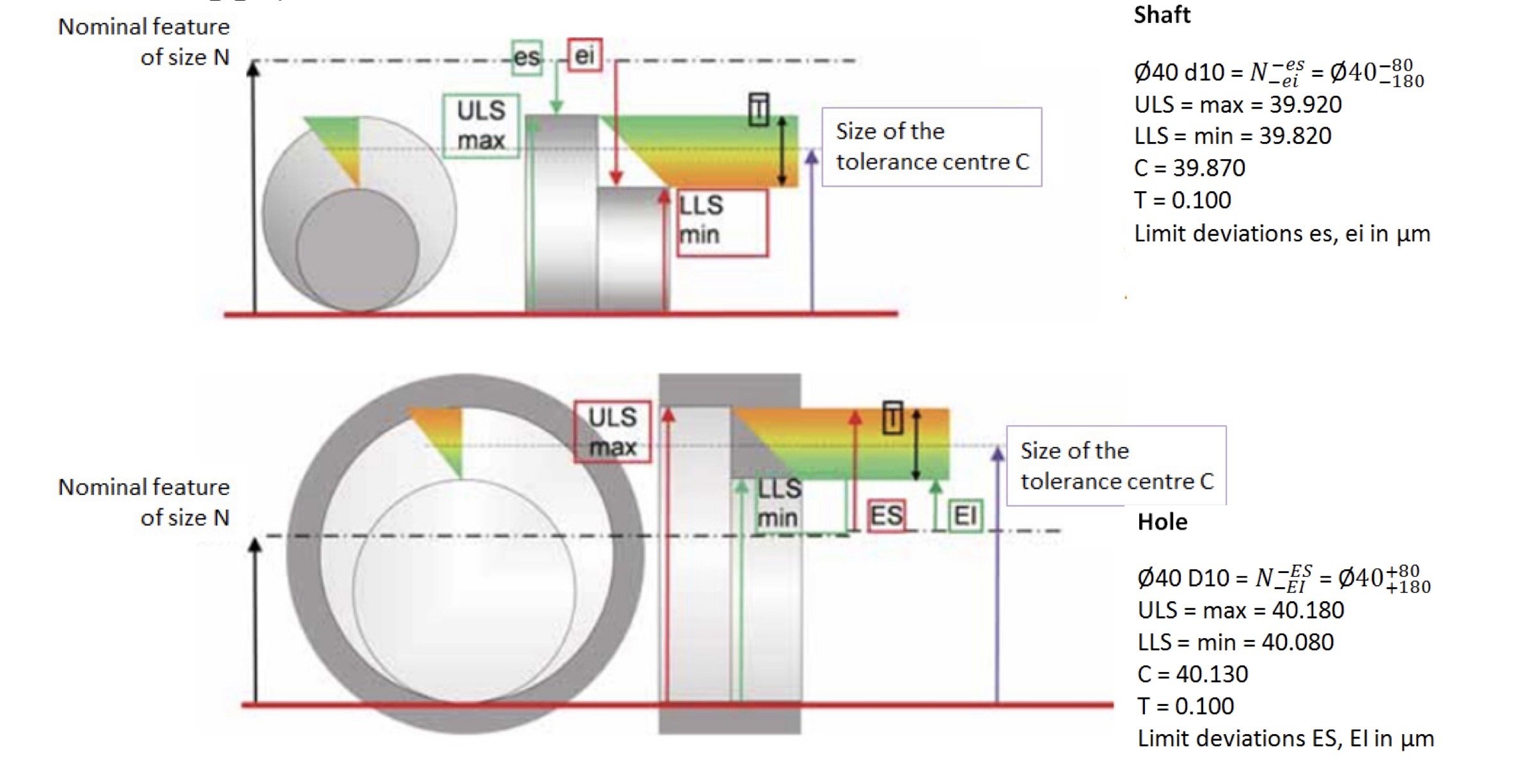

ISO 14405 Series: Advancing Size Tolerancing in Geometrical Product Specifications

The ISO 14405 series forms a critical component of the Geometrical Product Specifications (GPS) framework, which standardizes the way dimensions and tolerances are specified and verified in engineering drawings and manufacturing processes.

The Unbroken Chain of Confidence: Integrating Measurement Traceability, Advanced Uncertainty Management, and Digital Confirmation in CMM Operations

The integrity of dimensional measurement, particularly within the Coordinate Measuring Machine (CMM) discipline, is governed by a stringent framework of international standards designed to ensure comparability, consistency, and absolute confidence in the results.

Updates are Coming to ISO 9001, 14001 and 45001

With the ISO 14001 being scheduled for the next release, even the registrars are beginning to instruct auditors on what to start to look for immediately.

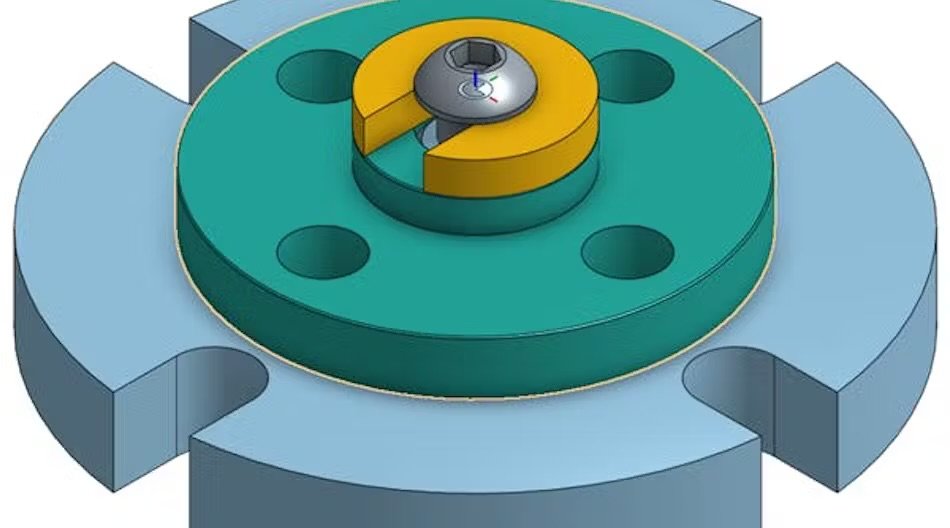

Ensuring Parts Fit, Using Bonus Tolerance to Your Advantage

Designers can use ASME Geometric Dimensioning and Tolerancing (GD&T), an internationally recognized symbolic language, to describe the acceptable limits of part feature variance.

Aerospace Auditing: How Its Impact Makes It a Smart Career Move

When it comes to the aerospace industry, there is no room for compromises in quality, consistency and safety. In 2025, flying hours are expected to hit record highs, requiring even more aircraft and services than what are currently available. With growing pressure, manufacturers face numerous challenges, including finding suitable suppliers amidst supply chain uncertainty, stocking up on inventory and continuing to produce quality products that help ensure safety for end use.

Beyond Compliance: The Importance of Standards in the Mobility Industry

The relentless pursuit of quality is the engine driving progress in the automotive and aerospace industries. Quality is the bedrock upon which customer satisfaction, operational efficiency, and, most importantly, safety is built.

Will the Next ISO 9001 Change Require More Training?

Let’s look at the processes the organization should go through to ensure effective management of whatever the 2026 version brings.

ISO Certification Needs to Change

The recent quality issues in Boeing aircraft, despite the company’s adherence to ISO 9000 and AS 9100 certification standards, have exposed significant gaps and weaknesses in the current certification processes. The ISO international organization needs to make the necessary changes to these certification standards to better ensure the true quality and safety of aerospace products.

How to Read & Interpret ISO/IEC 17025 Calibration Certificates

This article is an adaptation of my popular presentation, “Beyond the Sticker & the Cert (Ensuring Better Measurements & Reducing Risk).” Product manufacturers, testing labs, and calibration labs, in attempts to reduce risk and ensure better measurements, will have their measuring and test equipment (M&TE) calibrated so they can have their “sticker and a cert.” But how often do people actually read their calibration certificates?