You have choices, make the right choice

Revolutionizing Gear Inspection

Revolution is a powerful, but sadly overused marketing buzzword, despite the definition, it is often slapped on iterations of existing products, offering marginal gains in performance and/or productivity but still performing the same work, the same way. ZeroTouch Gear inspection respects the definition of the world when claiming to be revolutionary, delivering proven inspection methods where they have not been before, in-line.

PRECISION IN MOTION: A SUCCESSFUL SHOWCASE AT THE MOTION+POWER TECHNOLOGY EXPO

At the center of our showcase was the introduction of extended GT tailstock configurations — engineered to deliver greater range, stability, and precision for complex gear inspection applications.

These new tailstock options extend measurement flexibility, allowing operators to handle a wider variety of workpiece lengths and diameters while maintaining sub-micron accuracy. Designed for compatibility across our GT series gear inspection systems, they enable faster setup times, improved repeatability, and enhanced support for high-torque applications.

Gear Inspection Has Come a Long Way Since the 1920s

Gear inspection has undergone profound transformation since the early 20th century. What began as rudimentary evaluations for high-precision gears in the 1920s has evolved into a sophisticated discipline defined by standardized protocols, advanced instrumentation, and integrated digital ecosystems.

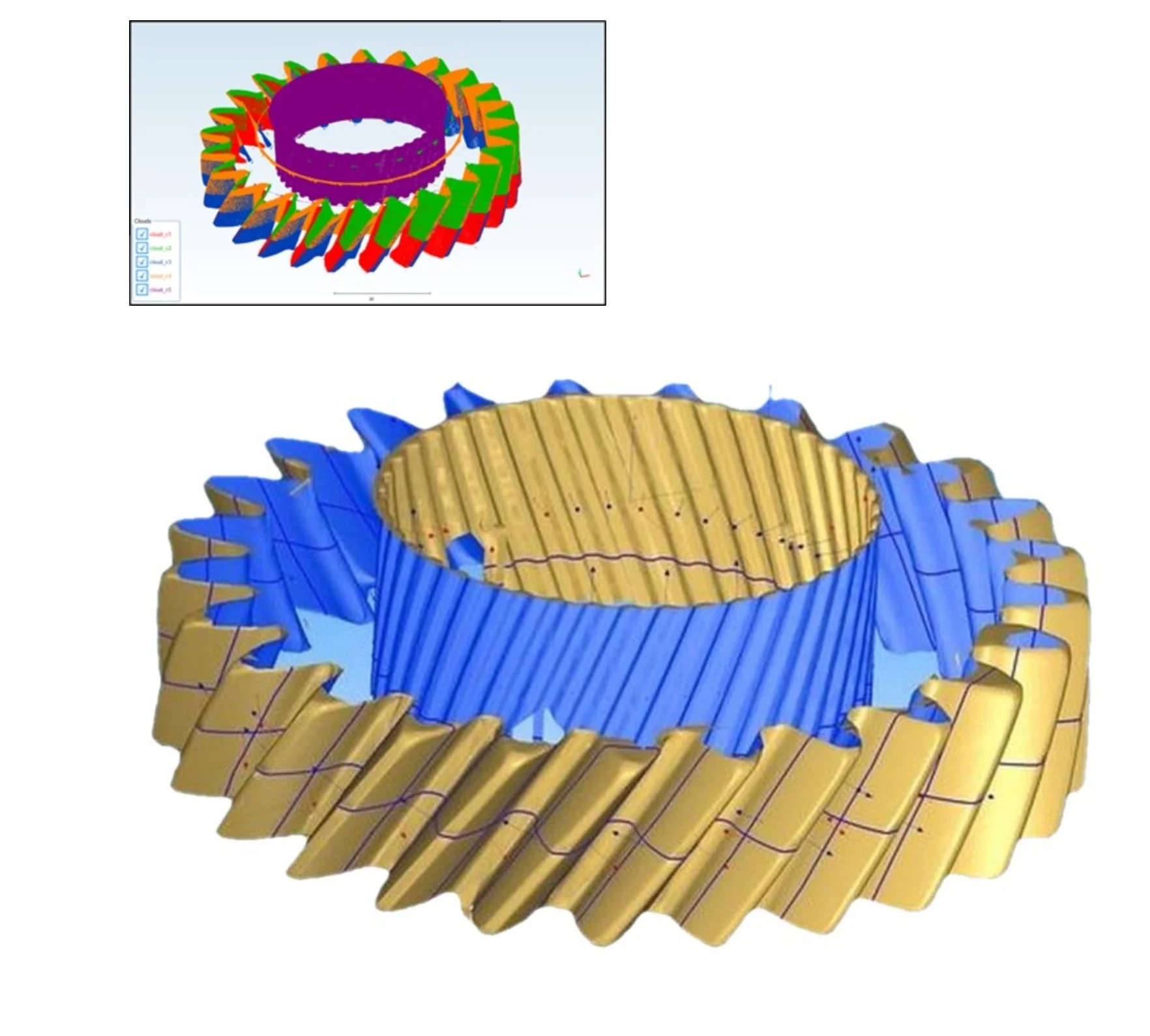

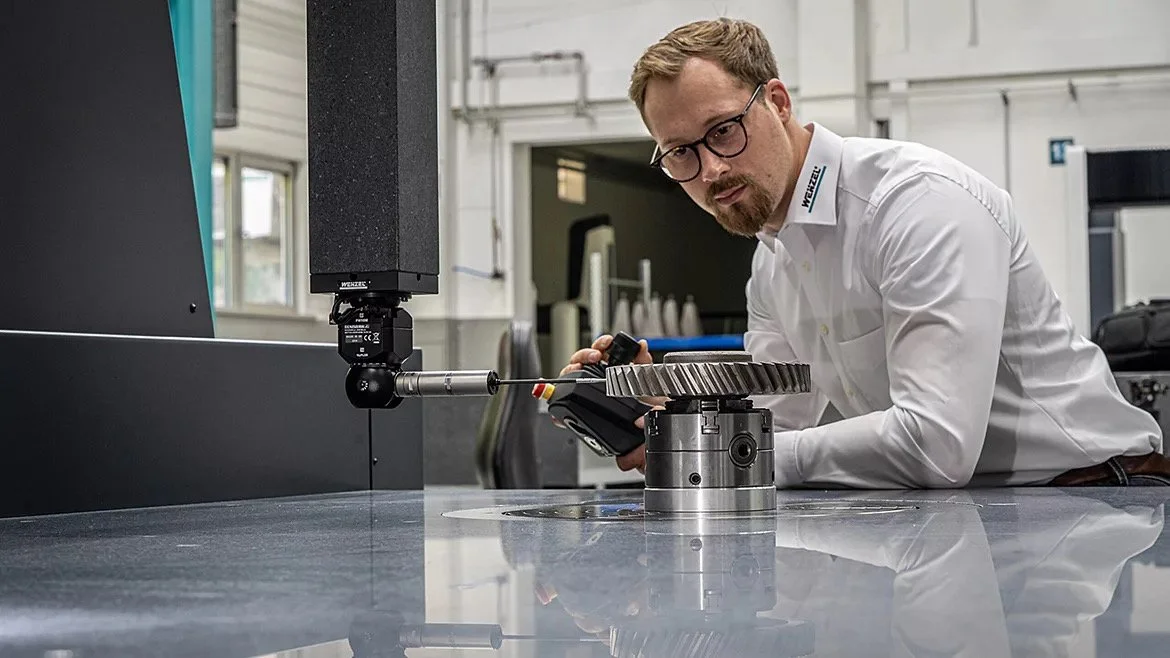

CONSIDER A CMM FOR GEAR INSPECTION

Gear inspection has long been considered a highly specialized, expensive and difficult part of the gear manufacturing process, requiring a wide variety of complicated gages, testers, dedicated CNC equipment and highly trained experts.

But if you want to make good gears, you need to have all that stuff, right?