You have choices, make the right choice

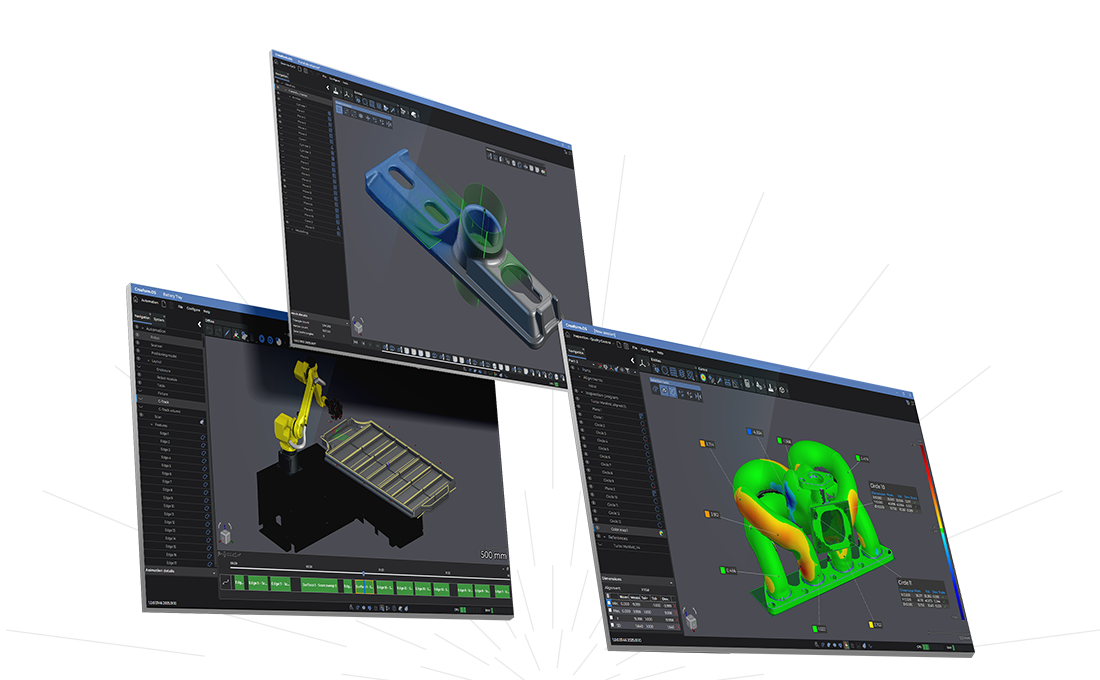

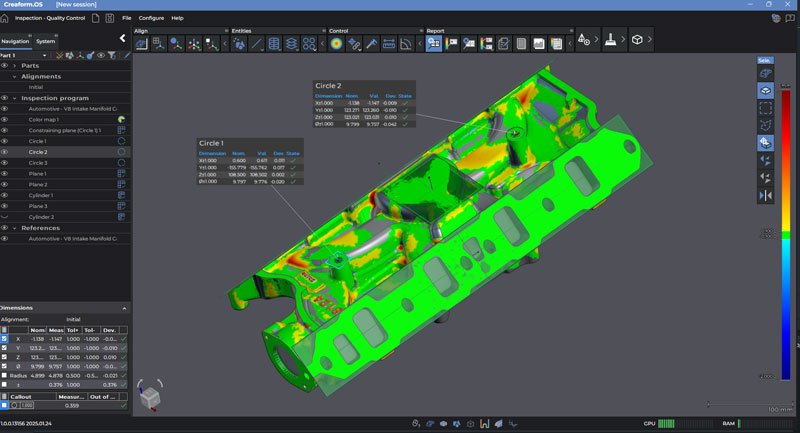

CREAFORM UNVEILS CREAFORM.OS AND CREAFORM METROLOGY SUITE: A LEAP FORWARD IN 3D MEASUREMENT SOFTWARE

Creaform Metrology Suite, its revamped 3D measurement software solutions. Previously known as VXelements, these new platforms focus on an intuitive user experience to streamline metrology workflows, benefiting professionals in reverse engineering, inspection, and automated 3D scanning

Revolutionising Quality Control: Turning The Ideal Into Reality

In manufacturing, achieving perfect quality control has always been an idea, until now. With rapid advancements in 3D scanning technology, industries can transform their quality control (QC) processes from reactive to proactive, ensuring precision, efficiency, and reliability at every stage.

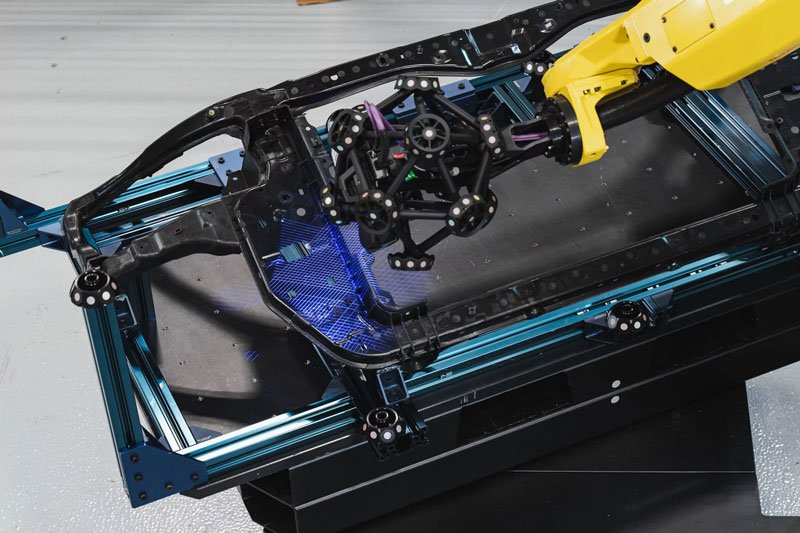

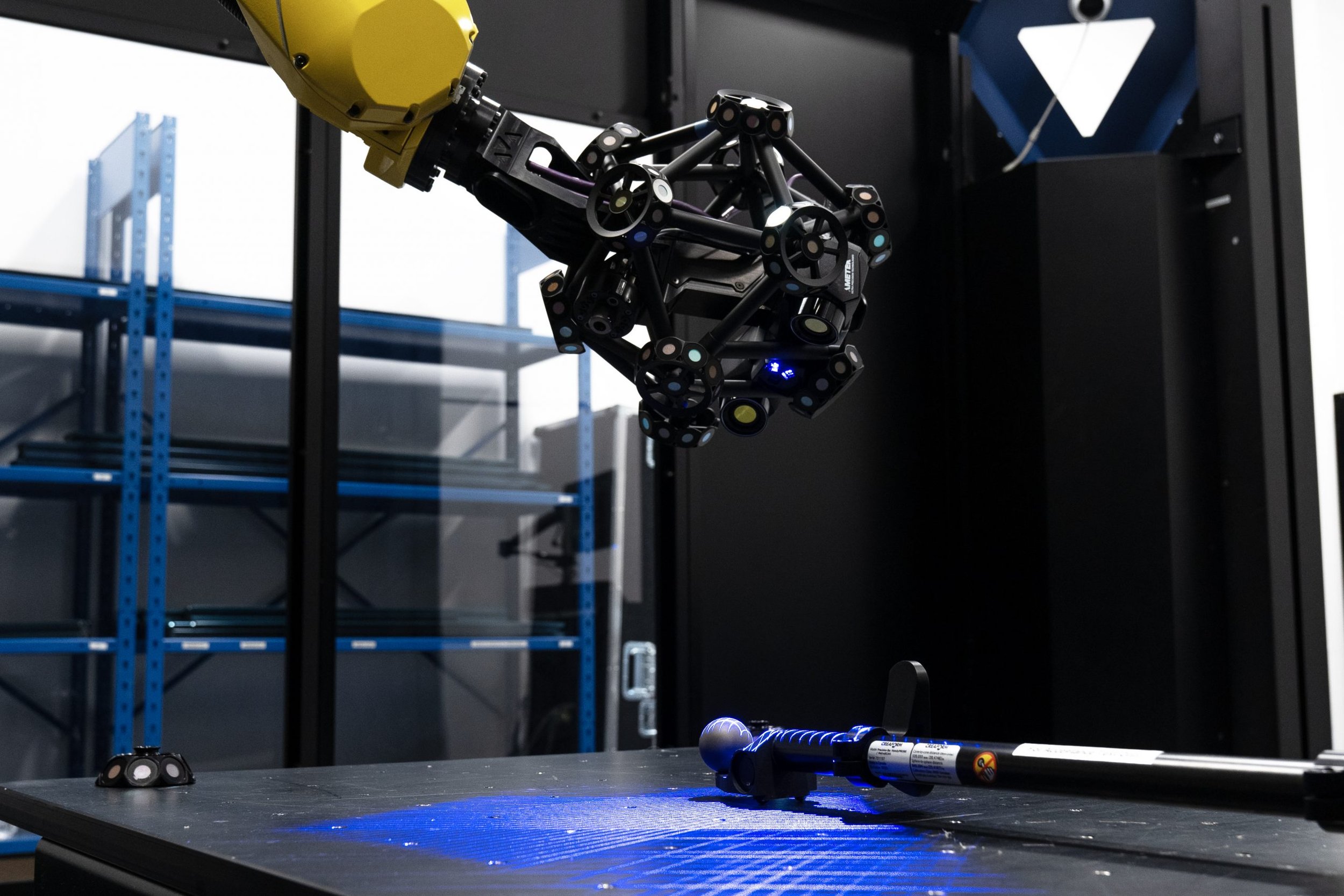

Tips on 3D Scanning & Automation | Creaform

In today’s manufacturing sectors, companies are continually confronted with various pressing challenges. Labor shortages and rising labor costs require innovative solutions to maintain productivity with less staff.

3 SIMPLE TESTS TO RECOGNIZE HIGH-QUALITY 3D SCANNERS WITH NO CALIBRATED ARTIFACTS REQUIRED

In today’s market, it seems like all 3D scanners have similar specifications, as if manufacturers look at their competitors’ data and use the same numbers. Datasheets, marketing videos, and even product appearances all look comparable, making it difficult to distinguish quality based on technical data alone.

3D SCANNING TO IMPROVE QUALITY CONTROL IN ADDITIVE MANUFACTURING PROCESSES FOR LARGE PARTS

There are tremendous benefits for companies in various sectors to leverage additive manufacturing processes and technologies, such as 3D printing, to create parts that are lightweight, yet strong. From accelerated prototyping to improved agility in customizing designs to significant reduction of surplus part inventory, additive manufacturing brings unprecedented efficiency and cost savings to manufacturing operations.

THE IMPACT OF 3D SCANNERS ON NASCAR STOCK CAR RACING

Reaume Brothers Racing is an American professional stock car racing team that competes full-time in the NASCAR Craftsman Truck Series. Owned by Josh Reaume, the team fields the No. 22 Ford F-150 full-time for multiple drivers, the No. 27 part-time for Keith McGee, and the No. 33 full-time for Lawless Alan.

INNOVATIVE 3D SCANNER SERVING THE LARGEST INDUSTRIAL PARTS A CREAFORM’S CLIENT SUCCESS STORY FEATURING SIEMENS ENERGY

With over 90,000 employees worldwide, Siemens Energy is a global company operating in various sectors of the energy industry, including grid technologies, decarbonization of industries, wind energy, and conventional power generation.

UNVEILING THE HIDDEN HURDLES OF AUTOMOTIVE PART MANUFACTURERS

Manufacturing sheet metal is far from a simple task. It requires rigorous inspection, primarily due to the high quality and stringent safety standards required in the automotive industry. No doubt, a combination of advanced technology and skilled labor must be involved to ensure that the sheet metal components are cut and shaped to precise dimensions. This includes checking for correct length, width, surface profile, and overall shape. Quality inspection is vital because automotive sheet metal must withstand stress and fatigue over the vehicle’s lifetime.

THE DIFFERENCE BETWEEN STATED ACCURACY AND ACCREDITED ACCURACY

How to Interpret the Accuracy of Measuring Instruments?

Stated accuracy refers to the accuracy that a manufacturer claims its measuring devices have, while accredited accuracy is an objective measurement of that product’s true accuracy.

CREAFORM ON BOARD TO HELP AMERICAN MAGIC WIN THE 37TH AMERICA’S CUP

At the end of August 2024, the New York Yacht Club’s American Magic set sail from Barcelona in its bid to win the Louis Vuitton 37th America’s Cup. According to organizers,

INNOVATION TAKES FORM: CREAFORM ELEVATES PORTABLE 3D SCANNING CAPABILITIES WITH ENHANCED HANDYSCAN 3D

With the most accurate BLACK Series yet, made possible through a new certification and the addition of key features, as well as a complete redesign of the SILVER Series, Creaform fulfills the evolving needs of metrology professionals and designers looking to improve their quality control and product development processes