You have choices, make the right choice

Seeing Beyond the Surface: Why Optical Metrology is Reshaping Quality Control

“In manufacturing, it’s often what we can’t see that causes the most problems.” That statement rings especially true for quality assurance professionals, where hidden deviations in surface geometry can make or break performance, safety, and compliance. As parts become smaller, more complex, and increasingly performance-critical, traditional measurement tools are reaching their limits. The solution? A shift from tactile to optical metrology — and with it, from reactive troubleshooting to predictive quality assurance.

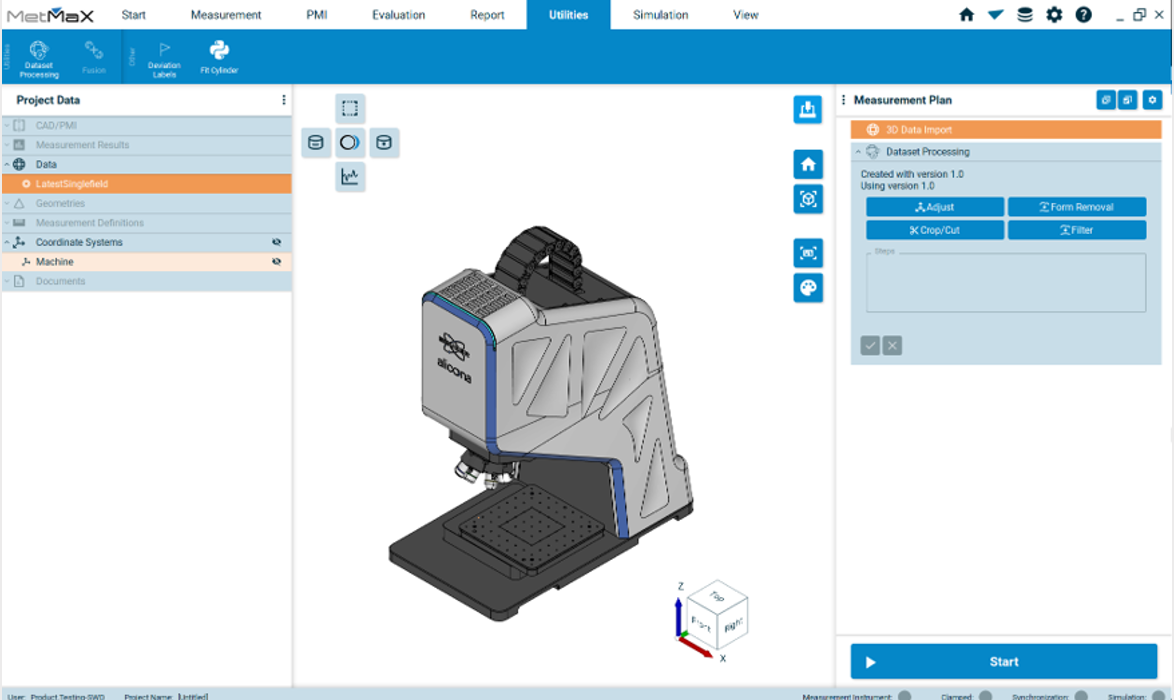

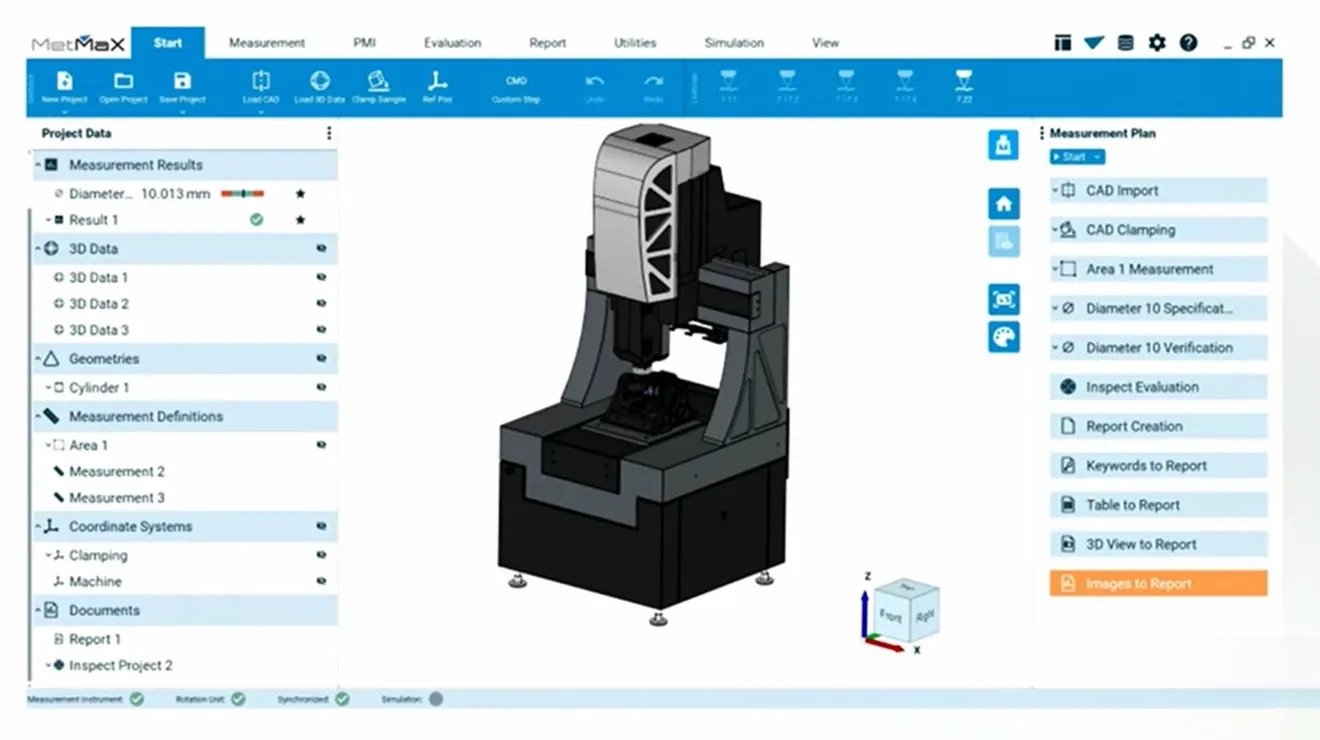

Contour Scanning powered by Focus Probing Technology

Experience a new era of efficiency and flexibility with contour scanning, an additional application of Focus Probing technology! With significantly increased speed and ease of use as well as extensive automation options, scanning contours is now even faster and more intuitive.

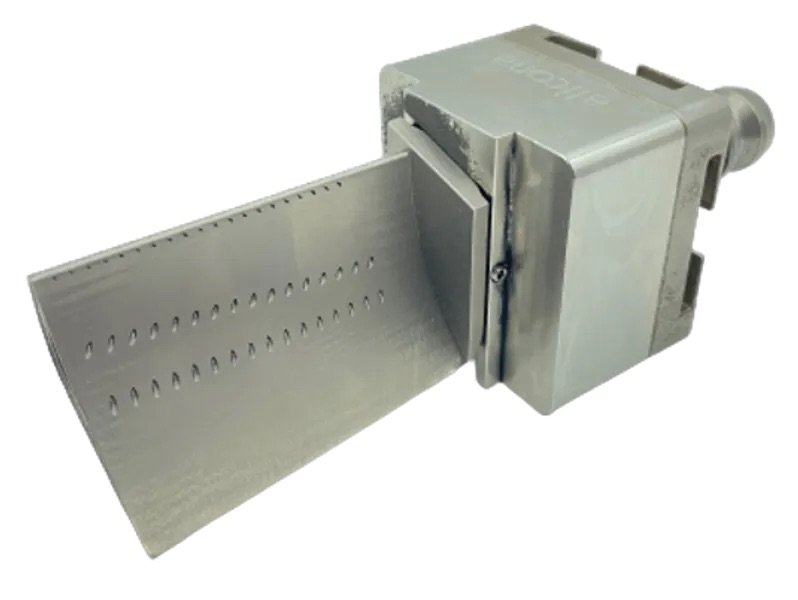

Why do you Drill Holes in your Turbine Blades

It's just the way life goes: You have a super important task and nobody knows about it. The best example is cooling holes in turbine blades. Very few people even know that they exist. Let alone what they are used for. Yet it is precisely these cooling holes that not only increase efficiency but also save lives in the aviation industry.

9 Do's & Don'ts in Optical Metrology for Maximum Accuracy

Your component is only as good as the quality control you can carry out on it. But how can you be sure that your measurement results are accurate enough? We have collected nine simple tips that will give you a real accuracy boost. Simple and incredibly effective.

Quality assurance of micro gears with optical metrology

Noise and vibration reduction of dental instruments is one of the joint goals of the wbk Institute of Production Science at the Karlsruhe Institute of Technology (KIT) together with the world-renowned manufacturer of dental products and technology,