You have choices, make the right choice

Is Your Quality Room The Issue When it Comes to Your Measurements

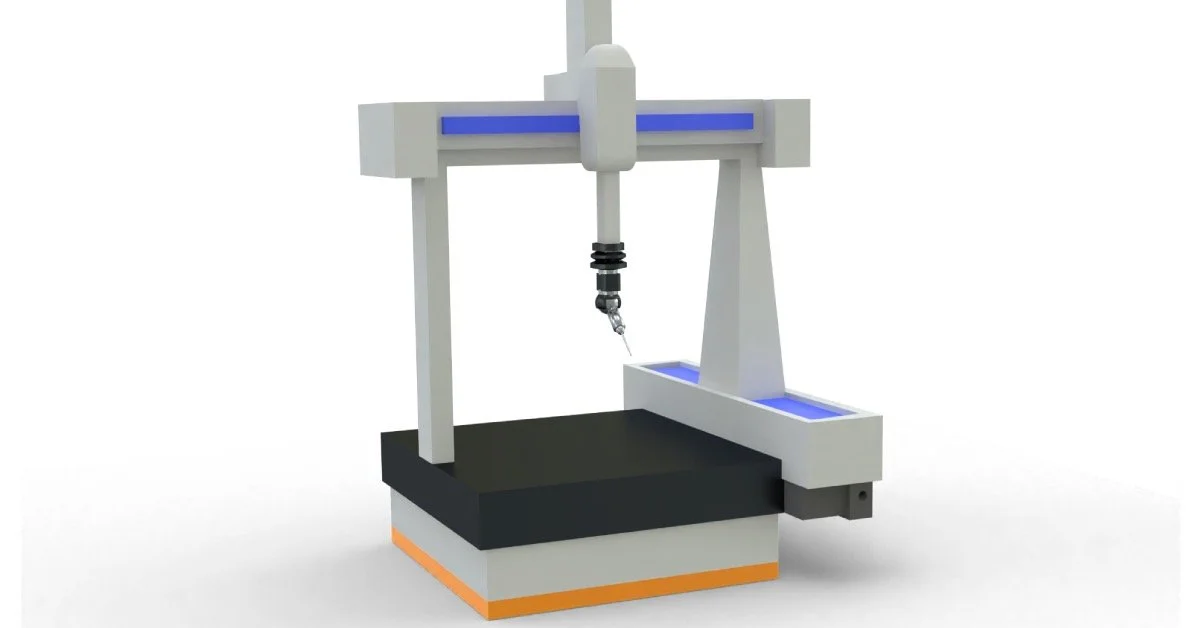

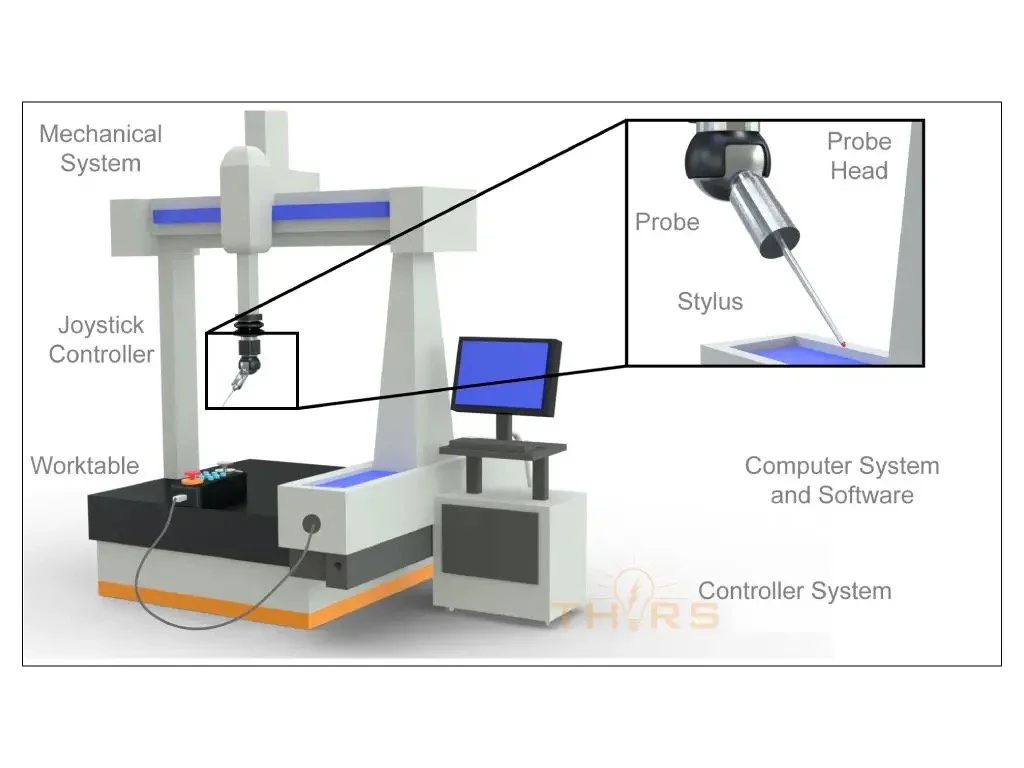

In the precision-driven world of manufacturing and quality control, Coordinate Measuring Machines (CMMs) stand as indispensable tools for ensuring dimensional accuracy and part conformity.

Understanding ASME B89.7.2: Dimensional Measurement Planning in Precision Metrology

In the field of precision metrology, ensuring the accuracy and reliability of dimensional measurements is paramount, particularly when using advanced tools like Coordinate Measuring Machines (CMMs).

ASME Y14.41: Pioneering Model-Based Definition in Modern Metrology

In the evolving landscape of manufacturing and engineering, the shift from traditional 2D drawings to fully digital, model-centric approaches has revolutionized how products are designed, produced, and inspected.

Understanding ASME Y14.5.1: Mathematical Definitions of Geometric Dimensioning and Tolerancing

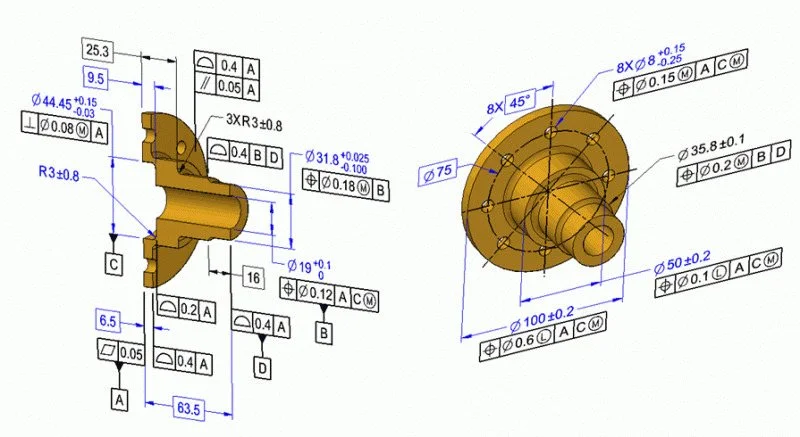

In the precision-driven world of metrology, where Coordinate Measuring Machines (CMMs) and advanced inspection technologies ensure parts meet exacting standards, Geometric Dimensioning and Tolerancing (GD&T) serves as the universal language for defining and communicating engineering tolerances.

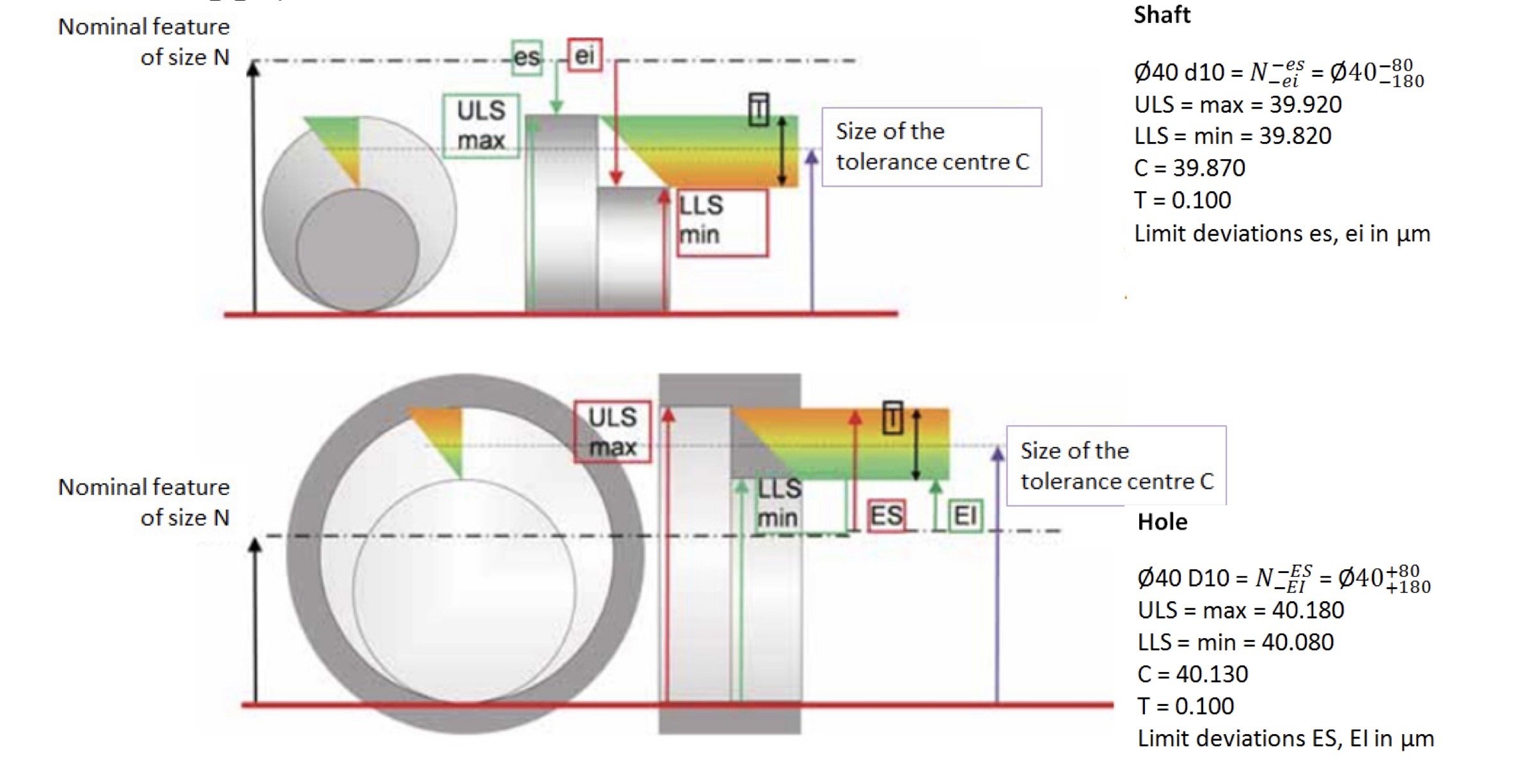

ISO 14405 Series: Advancing Size Tolerancing in Geometrical Product Specifications

The ISO 14405 series forms a critical component of the Geometrical Product Specifications (GPS) framework, which standardizes the way dimensions and tolerances are specified and verified in engineering drawings and manufacturing processes.

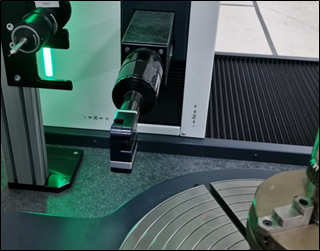

Measuring Roughness with Coordinate Measuring Machines

The measurement of roughness close to production is becoming increasingly important. In connection with the measurement of gears, roughness parameters are of great interest, for example, as they not only describe the surface topography in the micro- and nanometer range, but also characterize the running behavior of gearboxes. In addition to roughness, waviness also plays a role.

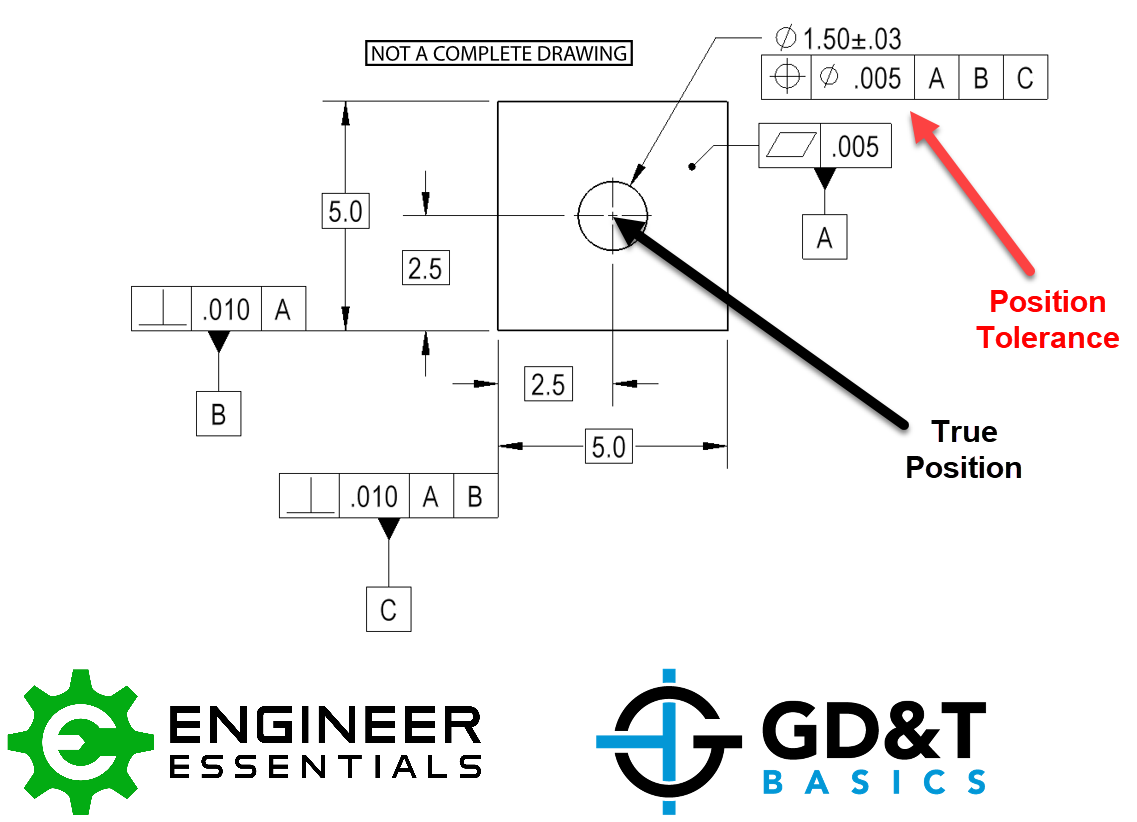

Ensuring Parts Fit, Using Bonus Tolerance to Your Advantage

Designers can use ASME Geometric Dimensioning and Tolerancing (GD&T), an internationally recognized symbolic language, to describe the acceptable limits of part feature variance.

Beyond Compliance: The Importance of Standards in the Mobility Industry

The relentless pursuit of quality is the engine driving progress in the automotive and aerospace industries. Quality is the bedrock upon which customer satisfaction, operational efficiency, and, most importantly, safety is built.

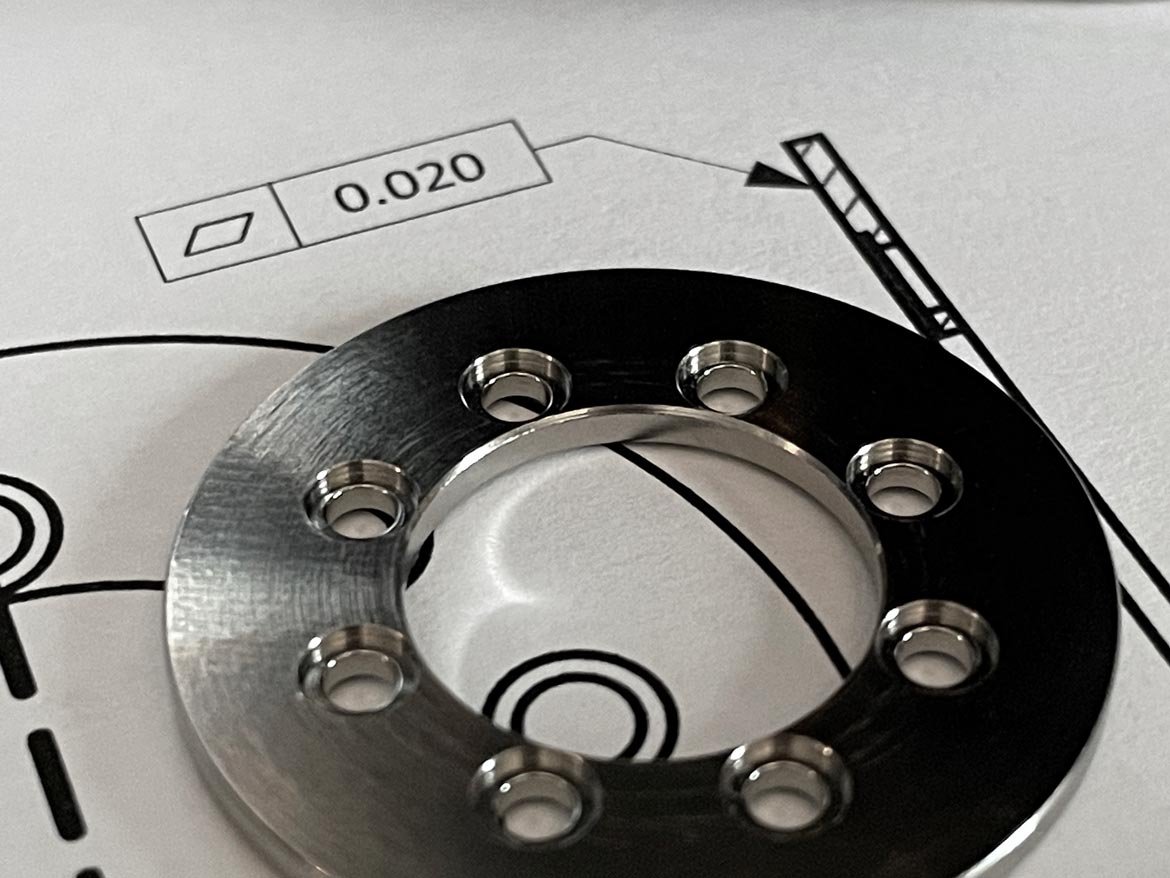

GD&T’s New Rule and What it means for Measurement

Here we will explore the implications of rule "S" and the limits/requirements of today's metrology as it is applied to these GD&T requirements.