How Xtreme Manufacturing Improved Quality and Inspection Efficiency Using the HandySCAN 3D|MAX Series

By Creaform

Xtreme Manufacturing offers the largest and most comprehensive line of heavy-duty and high-capacity telehandlers in North America. Known for their rugged performance and reliability in the most demanding environments, Xtreme places a strong emphasis on quality in every stage of production.

To uphold their commitment to quality when inspecting large weldments, Xtreme Manufacturing needed a solution that could deliver fast, accurate, and versatile measurements. Of all their requirements, speed proved especially critical to accelerating telehandler assembly. The solution they finally selected could meet these demands—combining high efficiency and accuracy with ease of use, without compromise.

This article explores how Xtreme Manufacturing improved their manufacturing quality and inspection efficiency by integrating the Creaform HandySCAN 3D|MAX Series into their workflow.

Inspection Challenges Impacting Assembly Efficiency

Before adopting Creaform’s 3D measurement technology, accurately inspecting large and heavy weldments posed a significant challenge for Xtreme Manufacturing. Manual inspection methods were not only time-consuming but also prone to letting defects slip through, occasionally reaching the assembly line and causing delays and costly rework.

With multiple large weldments requiring frequent quality checks, the company needed a faster and more reliable measurement solution. Speed was a particular concern, as slow inspection processes consistently risked disrupting production flow and creating bottlenecks.

The Need for Fast, Detailed Inspection on Large Weldments

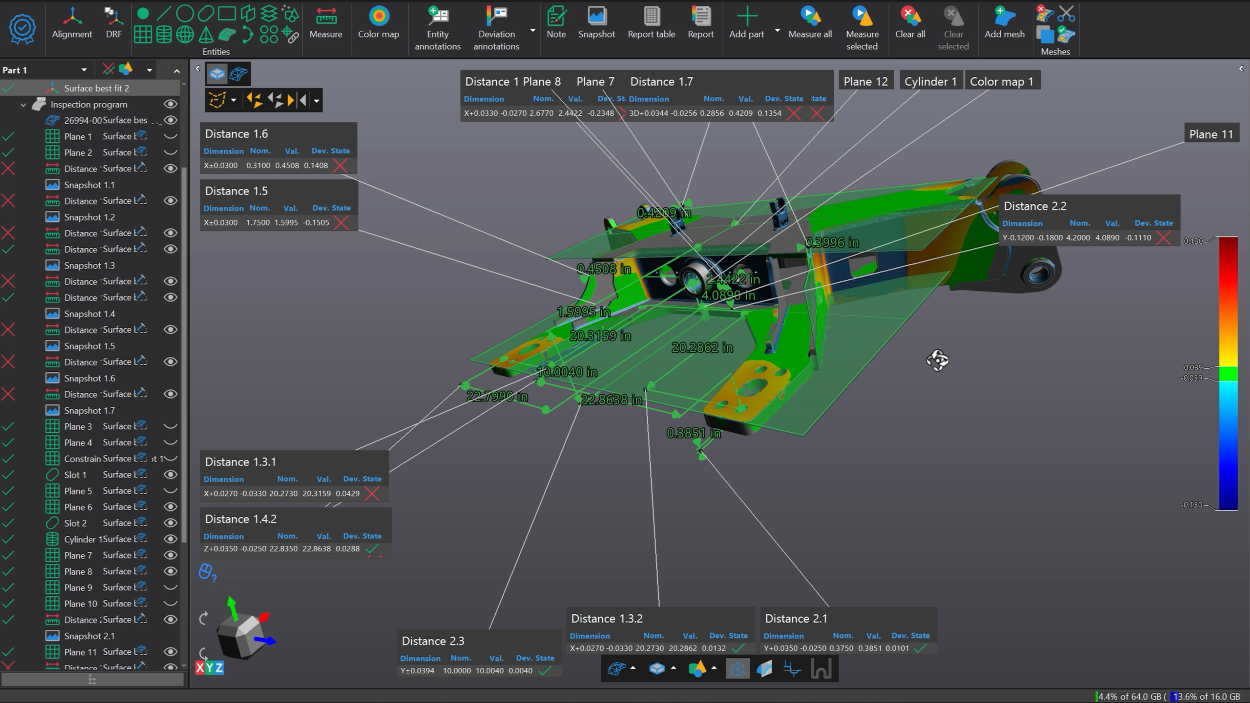

After evaluating several options, Xtreme Manufacturing selected the Creaform HandySCAN 3D|MAX Series for its ability to efficiently inspect multiple features on large weldments and generate detailed, inspection reports. One of the most appreciated capabilities was the ability to create an inspection file populated with all dimensions directly from the CAD model—ensuring a clear, one-to-one correlation between design intent and measurement results.

Moreover, integrating the HandySCAN 3D scanner into existing inspection workflows was effortless, and onboarding exceeded expectations. After just a few scans, the team quickly gained confidence using both the Creaform handheld 3D scanner and the Inspection software module of the Creaform Metrology Suite, making the implementation intuitive and seamless.

Resolving Issues Before They Hit the Assembly Line

The adoption of Creaform’s 3D scanning technology quickly began to pay off. In one case, Xtreme Manufacturing noticed a rise in outrigger base weldments that could not be installed on the machines during assembly. Rather than risk further disruption, they proactively pulled all 30 units from inventory and scanned each one to identify defects before they reached the assembly line.

This approach allowed them to isolate the issue early and prevent repeated delays. Moving forward, their team now has the ability to stay ahead of quality issues by quickly scanning inventory parts whenever needed—ensuring they “feel the pain” only once. As Adam Truster, Manufacturing Engineer, explains:

“The implementation of 3D scanning technology has greatly reduced production interruptions by quickly identifying quality defects before they escalate. This has streamlined our process, ensuring smoother operations and maintaining high product standards.”

Xtreme and Creaform: A Partnership That Delivers

Xtreme Manufacturing’s experience with Creaform has been overwhelmingly positive—from the responsive support team to the performance of the HandySCAN 3D scanning solution itself. Encouraged by the results, they plan to expand the use of the technology to inspect additional components such as telehandler chassis, booms, and carriage weldments before they reach the assembly line.

With Creaform, Xtreme continues to raise the bar in innovation and product quality. After all, innovation should simplify processes—not complicate them. By integrating Creaform’s 3D scanner into their workflow, they’ve enhanced quality control without disrupting operations—demonstrating that the right technology empowers better engineering outcomes.