Hexagon, Boeing and leading aero-engine companies form Rotor Dynamics Consortium to drive development of advanced modeling and simulation technologies

Hexagon’s Manufacturing Intelligence division and Boeing announce the formation of the Rotor Dynamics Consortium (RDC) in collaboration with some of the biggest names in the aircraft and aerospace engine industries. The RDC will define, drive, and standardise rotordynamics modelling and simulation requirements, with the goal of enabling airframers and aerospace engine manufacturers to safely overcome the engineering challenges of new more sustainable and efficient propulsion systems.

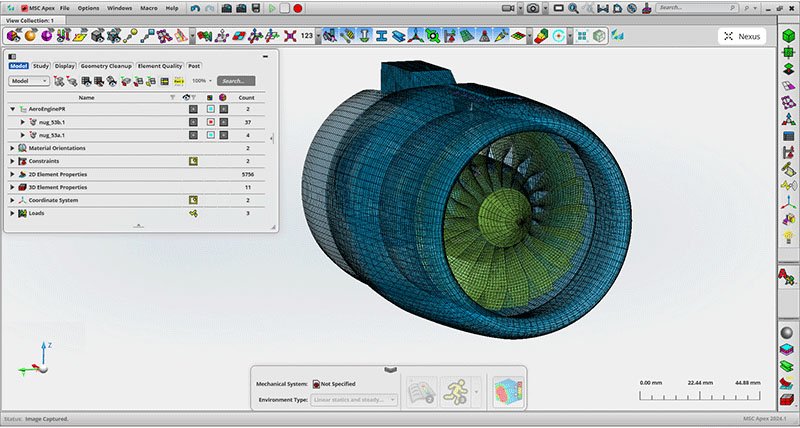

The consortium will build on finite element methods that are deeply embedded throughout design, validation and safety certification workflows to apply next-generation multiphysics simulations. The RDC will meet to discuss and formulate strategies on how best to apply MSC Nastran, which is considered the most accurate digital alternative to expensive physical testing, to overcome the unique challenges of engine rotordynamics and their downstream effects on airframe safety under different flight conditions.

As rotordynamics continues to evolve, achieving improved fuel efficiencies using the open rotor concept presents aerospace engine manufacturers with numerous challenges including vibration control, bearing design, and system stability. The phenomenon of windmilling, particularly post fan bladeout (FBO), poses significant challenges for engine design and the related aircraft safety certification. At the first RDC meeting on June 28th 2024, members will present and discuss new simulation solutions to help the industry meet regulatory compliance and develop an industry standard that applies the first of several planned enhancements to rotordynamics solution sequence SOL 128 Nonlinear Harmonics released in MSC Nastran May 2024 to improve windmilling analysis robustness and performance.

Commenting on the launch of the RDC, Subham Sett, Head of Multiphysics simulation at Hexagon said: “The industry needs simulation technologies that enable rapid innovation and confidence that engineering decisions are correct. The launch of the RDC marks a significant step by leading aerospace manufacturers to pioneer new simulation methodologies that shorten development cycles and facilitate the delivery of more efficient propulsion systems.

“MSC Nastran plays a pivotal role in structural validation, and we are committed to investing in innovative technologies to support the consortium's roadmap. Whilst driven by aero engine requirements, expect the technology advances will also help underpin progress in automotive and energy turbomachinery applications.”

Members will present on the topics of Rotordynamics Methods and Modelling and Non-linear Rotordynamics during the ASME Turbo Expo 2024 in London, following with the RDC Consortium Kickoff meeting will be held on Friday June 28th, 2024 at the conclusion of the event. This inaugural meeting will bring together aircraft industry experts and stakeholders in the field of rotordynamics modelling and simulation, fostering collaboration and advancing research and development. Confirmed participants include The Boeing Company, General Electric, Safran Aircraft Engines, Pratt & Whitney, Rolls Royce, Honeywell, MTU Aero and ITP Aero.