Digital Precision: How Simulation and Virtual Metrology Are Redefining Quality Control

Graphic 1: “Smart Manufacturing Stack”

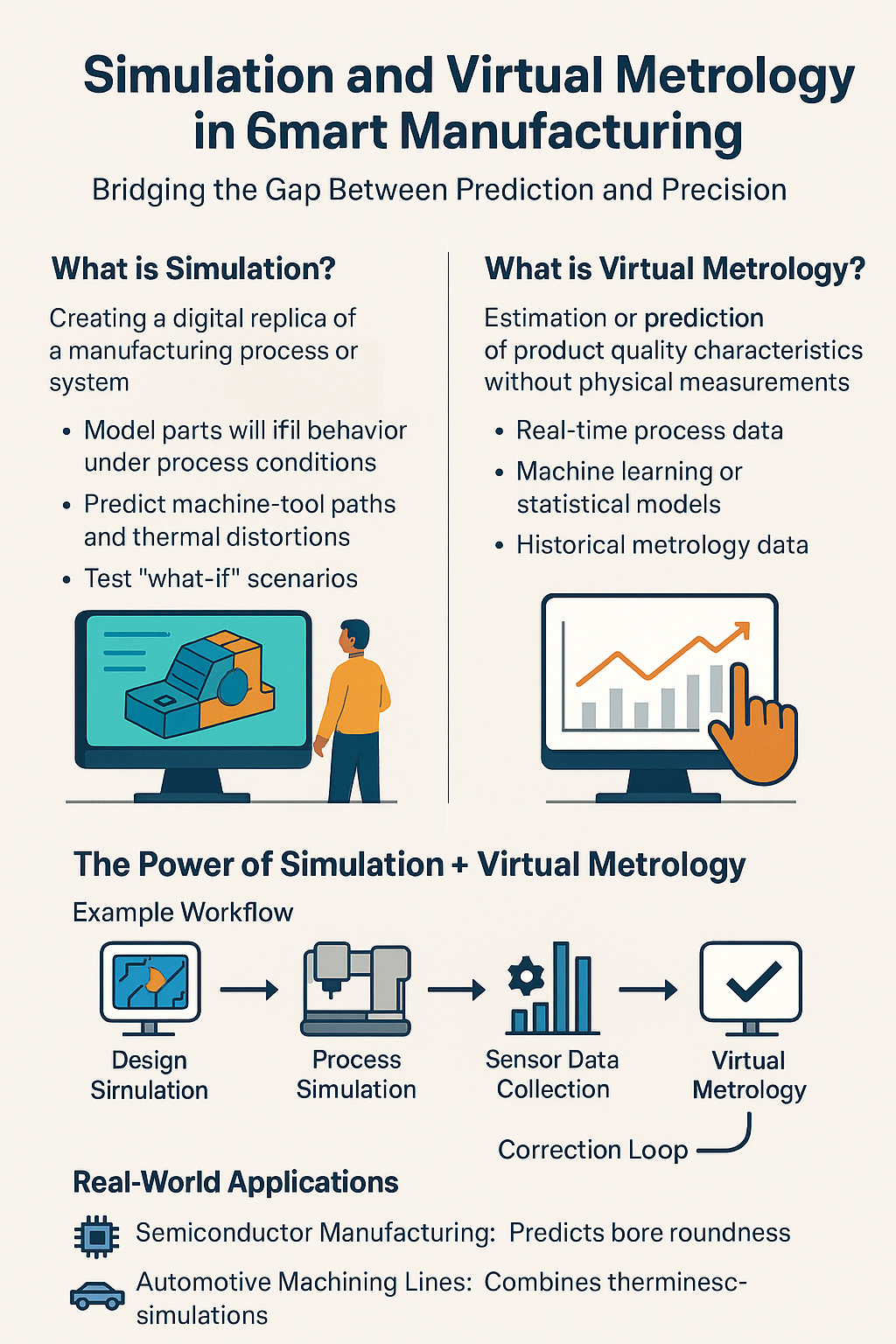

Overview Graphic

A layered diagram showing:

Digital Design (CAD/CAE)

Process Simulation (CAM, FEA, thermal models)

Real-Time Sensors

Virtual Metrology Models

Control Feedback Loop

What Is Simulation in Manufacturing?

Simulation in manufacturing refers to the creation of digital models that replicate real-world manufacturing processes, materials, and equipment. These models allow engineers and manufacturers to analyze and predict how a process or part will perform before any physical work is done. By simulating the behavior of materials under heat, stress, or motion—and by modeling machine operations, tooling paths, and even environmental conditions—manufacturers can optimize production parameters in a virtual environment. This reduces trial-and-error, minimizes scrap, and accelerates time-to-market.

Common applications of simulation include CNC toolpath planning, thermal distortion analysis in metalworking, injection molding process optimization, and additive manufacturing process control. These simulations are especially powerful when integrated into the early stages of product and process design, enabling predictive adjustments long before production begins.

One real-world example of simulation's impact is seen at Siemens Energy, where advanced simulation tools are used to optimize the production of turbine blades. By digitally modeling heat treatment cycles and stress distributions during manufacturing, Siemens was able to reduce material waste and production errors by 30%. This not only improved product quality but also enhanced energy efficiency and reliability in the final components.

You can read the full case study here:

Siemens Energy Case Study – Digital Twins for Turbine Blades

What Is Virtual Metrology?

Virtual Metrology (VM) is a predictive quality assurance technique that estimates a product’s key characteristics—such as dimensions, surface finish, or form—without the need for direct, physical measurements. Rather than relying solely on traditional inspection methods like coordinate measuring machines (CMMs) or laser scanners, VM uses real-time process data collected during production—such as temperature, pressure, torque, or machine speed—along with statistical or machine learning models trained on historical inspection data. These models correlate process conditions with measured outcomes, allowing manufacturers to predict quality in real time.

The advantage of virtual metrology lies in its ability to bring measurement and quality control closer to the process itself. By embedding prediction into the manufacturing workflow, manufacturers can detect deviations early, apply corrective actions immediately, and reduce reliance on time-consuming or destructive tests. This results in faster production cycles, fewer defects, and better use of metrology resources.

For example, semiconductor manufacturers often employ virtual metrology to monitor wafer characteristics such as film thickness or etch depth without halting production. In high-precision environments like this, the ability to make quality decisions instantly—without waiting for physical inspection—can lead to significant gains in both yield and efficiency.

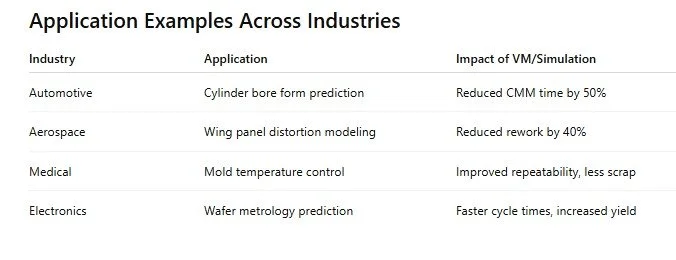

Graphic 2: “Virtual Metrology Model”

Simulation + VM: A Closed-Loop System

When simulation and virtual metrology are integrated, they form a powerful closed-loop system that continuously enhances process control and product quality. Simulation provides a predictive model of how manufacturing processes are expected to behave under various inputs and conditions, while virtual metrology uses real-time sensor data and predictive analytics to estimate actual product quality during production. By comparing predicted quality outcomes with VM estimates or occasional physical measurements, manufacturers can detect discrepancies, adjust parameters dynamically, and refine both simulation models and VM algorithms over time.

This closed-loop framework allows for proactive intervention—machines can self-correct, operators receive immediate feedback, and manufacturing lines become increasingly autonomous. It also enables a true digital twin environment, where every part and process has a live digital representation that evolves in sync with physical operations.

A notable example of this integration can be seen at TSMC, one of the world’s leading semiconductor manufacturers. TSMC uses virtual metrology alongside process simulations to predict key characteristics like wafer thickness and electrical properties after etching, all without interrupting production. By implementing this combined approach, the company has reduced its inline measurement requirements by 60% while maintaining tight quality control across extremely high-volume output. You can explore the case study here:

Key Benefits

Faster Quality Feedback

Lower Cost of Inspection

Continuous Process Optimization

Early Defect Detection

Enabler for AI/ML in Production

Implementation Challenges

While the benefits of simulation and virtual metrology are significant, implementing these technologies in a real-world manufacturing environment presents several challenges. One of the most critical factors is data integrity—the effectiveness of virtual metrology models and simulations depends heavily on the quality and consistency of the input data. If sensors are miscalibrated or data streams are incomplete, predictions can quickly become unreliable. Additionally, ensuring model accuracy is a constant concern. Predictive models must be rigorously validated and regularly updated with fresh production data to remain effective, especially when dealing with process drift or equipment wear.

Another common hurdle is integration complexity. Many factories rely on legacy equipment and siloed software systems that were never designed to support digital twins or real-time analytics. Bringing these elements into a unified, data-driven environment can require significant investment in infrastructure, software interoperability, and cybersecurity. Furthermore, organizational adoption is often overlooked but equally important. Engineers, operators, and managers must be trained not only to understand the predictions but also to trust and act on them. Gaining that trust can be difficult if the digital outputs contradict traditional inspection methods or prior experience.

Overcoming these challenges requires a combination of technical innovation, change management, and long-term investment. When approached strategically, the payoff is a more agile, intelligent manufacturing system that is capable of delivering consistent quality at scale.

Case Study: Hexagon AB & Boeing

Hexagon partnered with Boeing to simulate and measure fuselage panel curvature. By integrating virtual metrology with in-line sensors, Boeing reduced inspection time by 70% and streamlined assembly.

The Future of Smart Quality

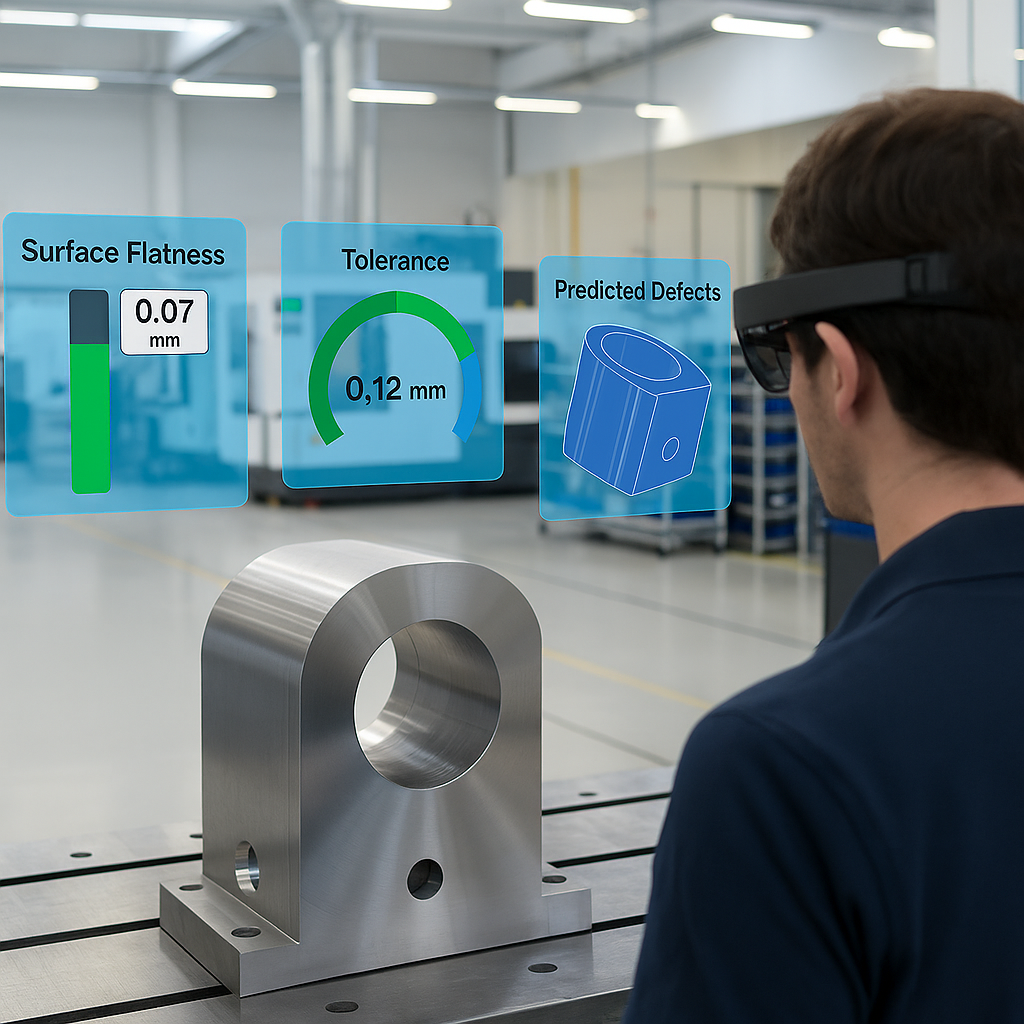

The future of smart quality in manufacturing is being shaped by rapidly advancing technologies such as artificial intelligence, edge computing, and augmented reality. AI-driven adaptive models will continuously update based on live production data, allowing predictive systems to become more accurate and responsive over time. Edge computing will enable these sophisticated prediction models to run directly on machines or sensors, reducing latency and improving real-time decision-making. Additionally, virtual inspection results will become fully integrated into traceable quality records, supporting digital certification processes and enhancing transparency. Augmented reality will further revolutionize quality control by overlaying predicted defects and tolerance information directly onto parts, providing operators with intuitive visual guidance and accelerating inspections. Together, these innovations will drive manufacturing toward zero-defect production, where quality is continuously monitored, predicted, and optimized without interrupting the flow of operations.

Graphic 3: “Future Vision of Quality Control”

A factory floor with virtual gauges and prediction overlays visible on machines or workpieces via AR devices.

Conclusion

Simulation and virtual metrology are not just tools; they are foundational technologies that transform how manufacturing achieves precision, speed, and scalability. Their integration allows manufacturers to predict outcomes, adjust in real time, and continuously improve—all while reducing reliance on manual inspection.

As digital twins, real-time data, and AI converge, the concept of zero-defect manufacturing becomes more achievable. For organizations aiming to compete globally in a fast-paced, precision-driven world, these technologies are not optional—they are essential.