Calypso: Alignment from Several Curves

Calypso is a coordinate measuring machine (CMM) software package by Carl Zeiss AG, designed to simplify the measurement of complex workpieces. One of its key features is alignment from several curves, a specialized method used when a part's orientation is defined by its complex, free-form surfaces, rather than simple geometric shapes.

How It Works

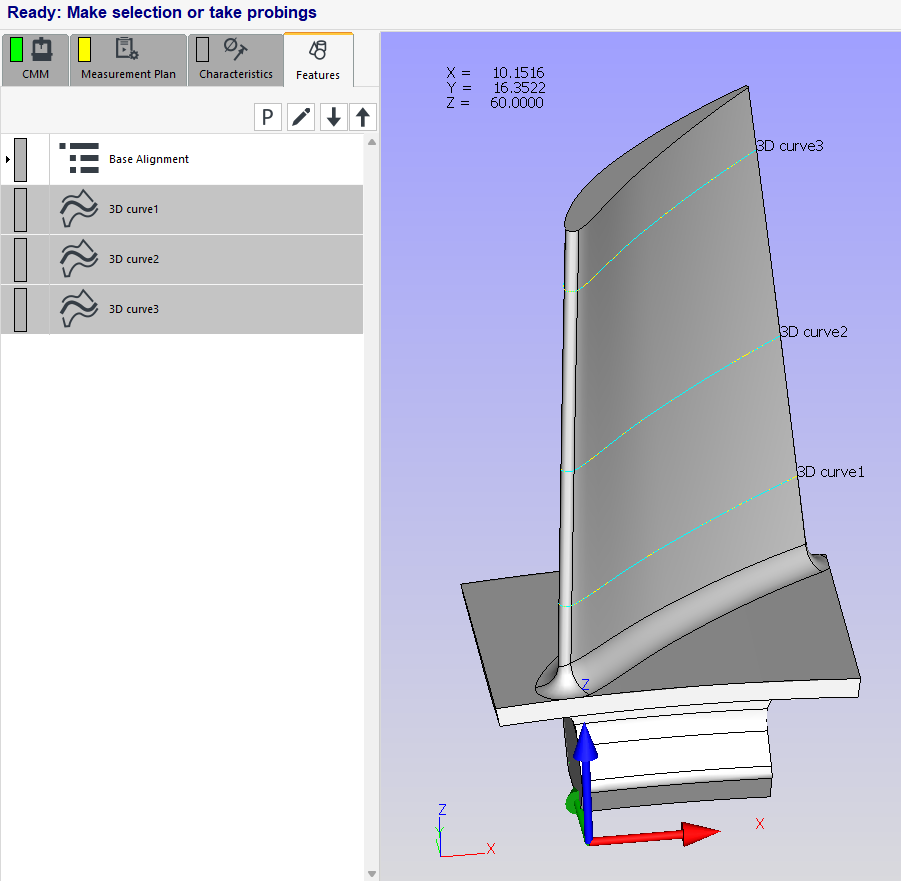

The alignment from several curves establishes a coordinate system by using a series of measured points on multiple curves. In this example we will use a turbine blade. This process involves:

Create the Base Alignment: The base alignment must be created first.

Measuring the curves: The CMM probe measures a series of points along two or more curves on the workpiece. These curves serve as the reference for alignment.

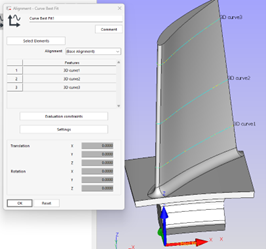

Defining the alignment: The user specifies how the measured curves relate to the desired coordinate system. Resources/ Utilities/ Alignment from Several Curves.

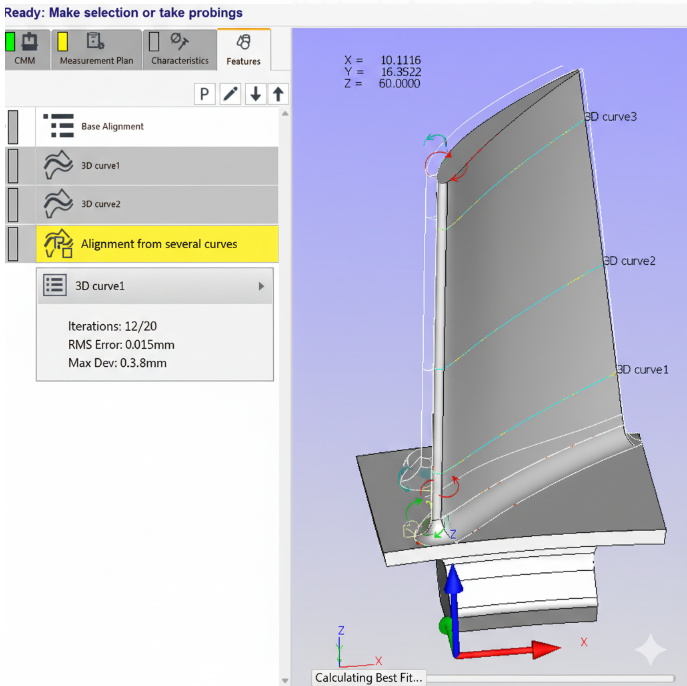

Calculation: Calypso’s software uses an iterative algorithm to best-fit the measured curves to their nominal (CAD model) positions, minimizing the deviation between the measured data and the ideal geometry.

Click on Evaluation constraints to set the constraints. The default is all the constraints are applied,

When to Use This Method

This type of alignment is particularly useful in industries where parts have complex, non-prismatic shapes, such as the automotive, aerospace, and medical sectors. For example, it is ideal for aligning car body panels, turbine blades, or orthopedic implants, where a traditional alignment based on simple geometric elements would be insufficient.

The Role of a Base Alignment

A base alignment must be defined first, even when using the "Alignment from Several Curves" feature. The base alignment is the foundational coordinate system for the entire CMM program. It provides a rough location for the part on the CMM, allowing the software to find the part's features and execute the more complex alignment from several curves. The "Alignment from Several Curves" is considered a secondary alignment that refines this initial base alignment.

Can This Alignment Be Used with a Profile Callout?

Yes, this type of alignment can be used when a profile of a surface callout is specified without any datum features. This is a common application for parts like turbine blades, where the entire blade surface is defined by a single profile tolerance.

The alignment from several curves is essentially a best-fit alignment. It takes the measured points on the curved surface and aligns them to the nominal CAD model in a way that minimizes the total deviation. This perfectly matches the requirement of a profile of a surface tolerance that isn't referenced to a datum, as the tolerance zone is a uniform boundary around the true profile. The alignment establishes the coordinate system that all subsequent measurements are referenced to, and it is optimized to ensure the profile deviation is as minimal as possible across the entire measured surface.

Description

Master the foundation of precision measurement.

This book is a complete guide to understanding, applying, and mastering datums and datum alignments on CMMs (Coordinate Measuring Machines). Written by Mark Boucher, founder of CMM Quarterly, it distills decades of metrology expertise into clear, practical chapters designed for engineers, machinists, quality professionals, and students of GD&T.

From the basics of datum reference frames to advanced strategies like iterative and best-fit alignments, this book explains not just the how but also the why behind CMM alignment practices. Each chapter blends theory, industry standards (ISO/ASME), and real-world application with best practices, diagrams, and examples that can be applied immediately on the shop floor or in the lab.

What You’ll Learn

The fundamentals of datums and datum reference frames (DRFs).

Manual, CAD-based, best-fit, and iterative alignment strategies.

How fixturing and workholding affect measurement accuracy.

Managing measurement uncertainty and its impact on datum selection.

Troubleshooting alignment issues and preventing common errors.

Communication and reporting practices that build trust across teams.

Why This Book Matters

Accurate measurement starts with accurate alignment. Misapplied datums can lead to costly scrap, disputes with customers, and unreliable inspection results. This book gives you the knowledge and tools to confidently control datums, stabilize measurements, and produce results that stand up to scrutiny.

Who Should Purchase the Book

CMM programmers and operators.

Quality engineers and inspectors.

Design engineers working with GD&T.

Machinists and manufacturing leaders seeking better alignment practices.

Students and professionals looking to strengthen their metrology foundation.

Format: Digital Download