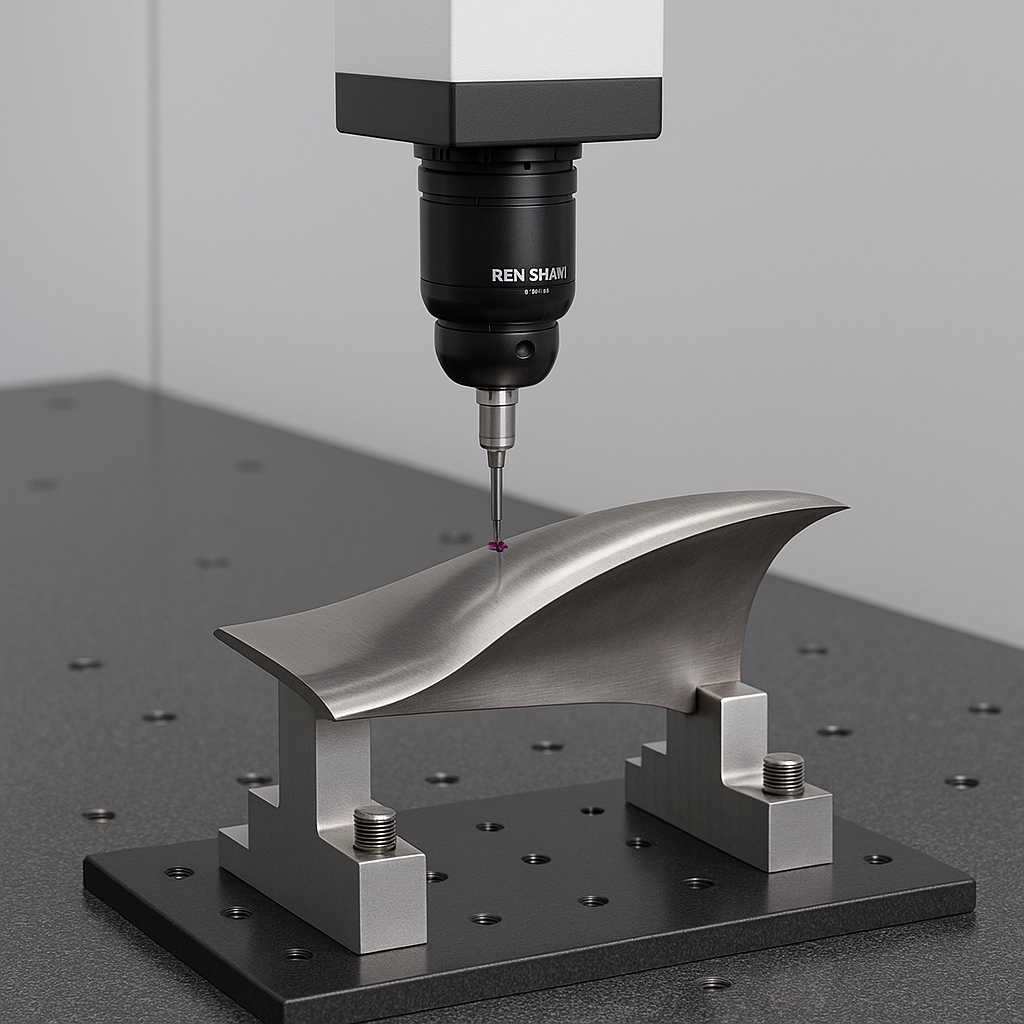

Precision Inspection of Airfoil Blades Using a Coordinate Measuring Machine (CMM)

Airfoil blades, essential components of turbines and jet engines, require extreme precision in their geometry to ensure optimal aerodynamic performance, structural integrity, and energy efficiency. Accurate inspection of airfoils is paramount, and Coordinate Measuring Machines (CMMs) have become the gold standard for achieving this. This article outlines the critical steps, methods, and tools involved in inspecting airfoil blades on a CMM, including alignment, probing strategies, and feature evaluation.

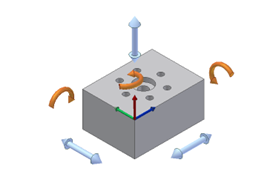

Understanding the 6 Degrees of Freedom (Copy)

Understanding the principle of the 6 degrees of freedom is essential to aligning your part correctly on the Coordinate Measuring Machine (CMM). When a part is placed on the CMM the location of the part is not known. It must be defined by using several features known as datums.