DMIS - Slot Parameters

DMIS Slot parameters

Written by CMM Quarterly

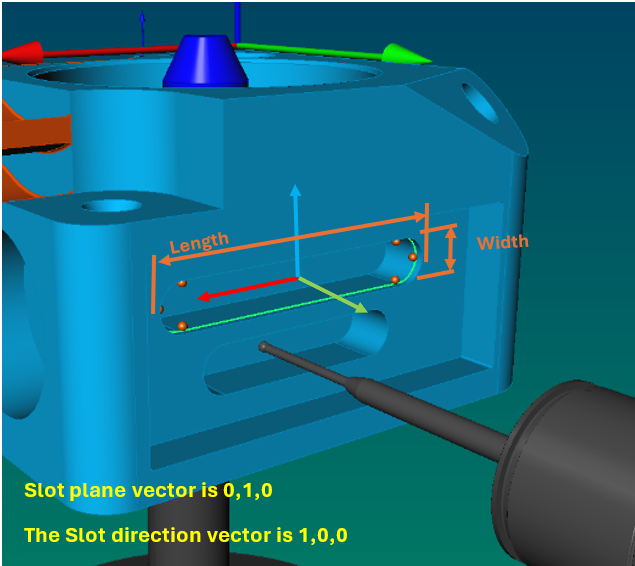

What makes up a slot in the DMIS code? Below is the parameter to create a slot.

Syntax:

F(name)=FEAT/CPARLN,dir,type,coord,x(r),y(a),z(h),i1,j1,k1,i2,j2,k2,len,wid

DMIS - Sensor Setting

An excerpt from the DMIS Handbook. Learn how to write programs in DMIS. This book will help you master the DMIS Language. Sensors Settings.

An excerpt from the DMIS Handbook. Learn how to write programs in DMIS. This book will help you master the DMIS Language.

In these DMIS articles we will start with the basics and move to more complex DMIS statements

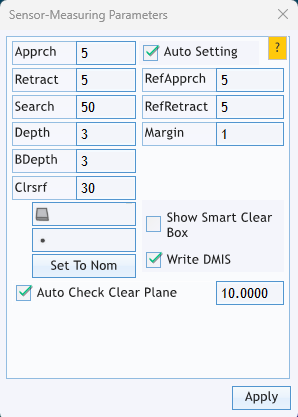

Syntax:

SNSET/setting_type (,reference), value

DMIS syntax at the beginning of a program.

SNSET/APPRCH, 5.0000, ON

SNSET/RETRCT, 5.0000, ON

SNSET/SEARCH, 50.0000

SNSET/DEPTH, 3.0000, 3.0000

SNSET/CLRSRF, 30.0000

Again, your software input may look different, but it is shown here to demonstrate how a CMM software allows the input that will be written in the DMIS code.

APPRCH

Approach controls the distance from a feature nominal that the CMM will depart the POSVEL (Position Velocity) and move into MESVEL (Measurement Velocity).

SEARCH

Search controls how far the CMM will search for a touch point along the normal vector set in the nominal feature statement.

RETRCT

Retract controls the distance the probe will move away from a probed touch point.

Here we changed the retract to 8mm with a 5 mm approach

Care must be taken in a diameter, slot, etc..., any feature with an opposing wall so that either the approach or the retract will not the wall.

CLRSRF

CLRSRF – provides the clearance plane height for the stylus to travel to the next feature.

CLRSRF

Green - Path with reference

Red - Path without reference

Yellow - CLRSRF

Example:

SNSET/CLRSRF, 30.0000

Sets the clearance surface height to 30mm

Unlock the power of native DMIS (Dimensional Measuring Interface Standard) programming with this hands-on, example-driven digital handbook from CMM Quarterly. Designed to demystify CMM (Coordinate Measuring Machine) scripting, it’s your practical guide to mastering advanced DMIS techniques—all delivered in a downloadable PDF format for convenience and instant access.

What’s Inside

Clear Command Syntax: Grasp key DMIS structures like SNSDEF, CONST/POINT, and the differences between MAJORWORDS and MINORWORDS, with focused explanations for better clarity.

Feature & Tip Definitions: From midpoint calculations to defining custom probe tip shapes (SNSDEF/PROBE,…DISC), practical examples guide you through each step.

Sensor & Mode Programming: Learn crucial DMIS commands—SNSET/APPRCH, RETRCT, CLRSRF, and more—with real-world application examples for reliable routine creation.

Readable Formatting: Consistent layout and color-coding help differentiate keywords from parameters, enhancing comprehension and reducing syntax errors.

Highlights & Audience

Hands-On Learning: Packed full of authentic DMIS code snippets to guide you through common metrology tasks and scripting scenarios.

Ideal for New to Intermediate Users: Perfect for CMM programmers transitioning from GUI-based environments or those aiming to refine DMIS scripts.

Bridges Concept with Practice: Seamlessly takes you from basic syntax to advanced scripting essentials useful in daily use.

Things to Keep in Mind

Not a Substitute for Official Standards: While thorough, it doesn't replace the ANSI/ISO 22093 standard or the NIST DMIS Test Suite for formal compliance or deep technical reference.

Summary

The DMIS Handbook is a strong, example-rich introduction to DMIS scripting—clear, readable, and practical. It’s especially useful for CMM operators, metrologists, and programmers aiming to enhance script accuracy and readability. For best results, pair it with the official ISO/ANSI standards and NIST reference manuals if your work demands strict compliance or integration with advanced systems.

This book is a digital download

Indexing Head with Cylinder or Disc Tip

DMIS statement for creating a cylinder or disc tip.

An excerpt from the DMIS Handbook

DMIS statement for creating a cylinder or disc tip.

Syntax:

S(name)=SNSDEF/PROBE,type,POL,rot1(A),rot2(B),i, j, k, len ,dia, tip(,value)

Example:

S(DISK1)=SNSDEF/PROBE,FIXED,POL,0,0,0,0,1,115,12,DISC,3

The above defines a disc tip (DISK1) that is a fixed probe with a angular rotation of 0/0. The mounting vector is 0, 0, 1 with a length (from pivot center to the tip center) of 115.

The disc diameter is 12mm with a 3mm thickness.

Note: discs and cylinder tips should be used bi-directional, in other words normal to a work plane and not 3 dimensional as a sphere tip would be used.

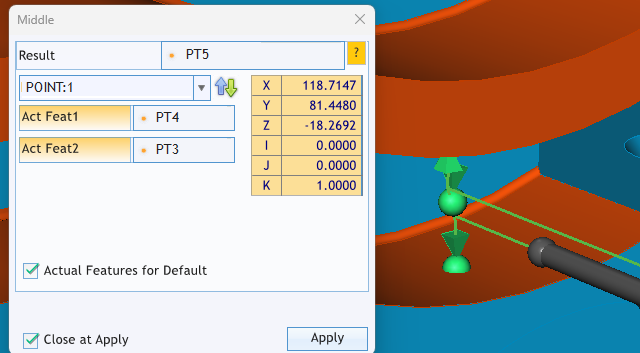

POINT - Mid Point

A mid point construction consists of the point to be created and the names of two other measured, constructed, or defined features or feature definitions. The mid-point will be the center of a 3D line between the centers of the 2 features used in the construction.

A mid point construction consists of the point to be created and the names of two other measured, constructed, or defined features or feature definitions. The mid-point will be the center of a 3D line between the centers of the 2 features used in the construction.

Syntax:

CONST/POINT,F(name),MIDPT,FA(name), F(name)

or

CONST/POINT,F(name),MIDPT,FA(name), FA(name),

Parameters

F(name),

Defined name of the point being constructed

MIDPT

The point will be constructed as the mid-point between 2 features

F(name), or FA(name

Name of previous measured, constructed, or defined features

Example:

F(PT5)=FEAT/POINT, CART, 118.7147, 81.4480, -18.2692, 0.0000, 0.0000, 1.0000

CONST/POINT, F(PT5), MIDPT, FA(PT3), FA(PT4)

DMIS Language Syntax

DMIS Language Syntax

DMIS is a programming language that allows programs to be read and modified by programmers. These programs are stand alone and should contain everything that would allow a programmer to execute the program.

DMIS dictates that each measurement feature be defined by the nominal parameters. These are derived from the blueprint or extracted from the CAD model.

Everything in DMIS must be defined such as sensors, datums, etc…

DMIS requires that all measurements are of a feature type and that these features must be defined before being measured or constructed. Before you can measure a feature you must first define the feature nominal parameters. For instance, in you want to measure a circle, you must first define the nominal position, direction and size and give it a name you will use when you issue a command to measure the feature.

What is DMIS?

DMIS is an information exchange standard published with the International Organization for Standardization (ISO). DMIS defines measurement process plan information for CMMs. Because DMIS is both human readable and computer readable (such as C++ or Java), it can be called a programming language for CMMs.

DMIS is an information exchange standard published with the International Organization for Standardization (ISO). DMIS defines measurement process plan information for CMMs. Because DMIS is both human readable and computer readable (such as C++ or Java), it can be called a programming language for CMMs. DMIS is a language, which means that software implementing DMIS must be able to encode DMIS or decode DMIS. Like any information exchange standard, this standard is intended to enable interoperability by allowing the use of DMIS programs, without alteration, on many types and brands of CMMs.

DMIS is written to control many types of CMMs, including computer numerically controlled (CNC), manual, classic touch-trigger, touch scanned, noncontact scanned, five-axis scanned and CMMs with rotary tables. Portable CMMs are typically not addressed by DMIS, including articulated-arm CMMs, laser trackers, white-light scanners, theodolites and robotic CMMs.

Because DMIS is so large and there are so many different functional applications, such as prismatic and thin walled, DMIS developers have defined conformance classes, which are essential for interoperability.

There are two common uses for DMIS:

Dimensional measurement planning software presents the metrologist with a 3-D computer-aided-design (CAD) model of the part to be measured and provides software tools to choose which features are to be measured and how they are to be measured-including specification of sensor types, sensor paths and distribution of points. The automatic output of the software is a measurement program encoded in DMIS.

The metrologist writes a DMIS program by hand and may debug it using a simulator.

In both scenarios, the measurement execution software then decodes the DMIS program and executes it on a CMM.

John Horst

DMIS Language Syntax

DMIS is a programming language that allows programs to be read and modified by programmers. These programs are stand alone and should contain everything that would allow a programmer to execute the program.

DMIS dictates that each measurement feature be defined by the nominal parameters. These are derived from the blueprint or extracted from the CAD model.

Everything in DMIS must be defined such as sensors, datums, etc…

DMIS requires that all measurements are of a feature type and that these features must be defined before being measured or constructed. Before you can measure a feature you must first define the feature nominal parameters. For instance, in you want to measure a circle, you must first define the nominal position, direction and size and give it a name you will use when you issue a command to measure the feature.

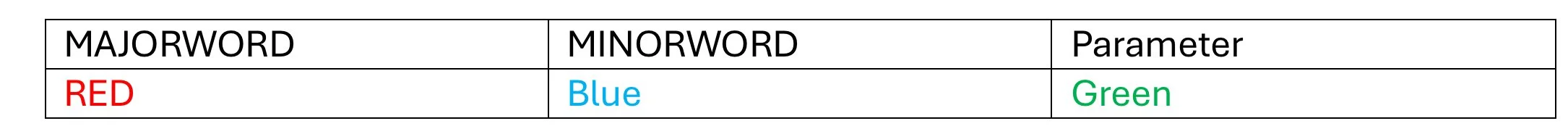

DMIS Command

Structure of a DMIS Command

In this book we will color code the statement(s) to help define the MAJORWORDS, MINORWORDS, and Parameters.

(name of variable=) MAJORWORD/ MINORWORD(S) and/or (parameter(s))

The example above shows the general syntax of a DMIS command or statement. If the command is an assignment it will start with the DMIS element/ name or variable followed by the equals sign and the MAJORWORD (identifies the command). If the command is not

an assignment it will start with a MAJORWORD that identifies the command. In all cases, the MAJORWORD will be followed by a forward slash which will be followed by MINORWORDS and/or parameters.

General Information:

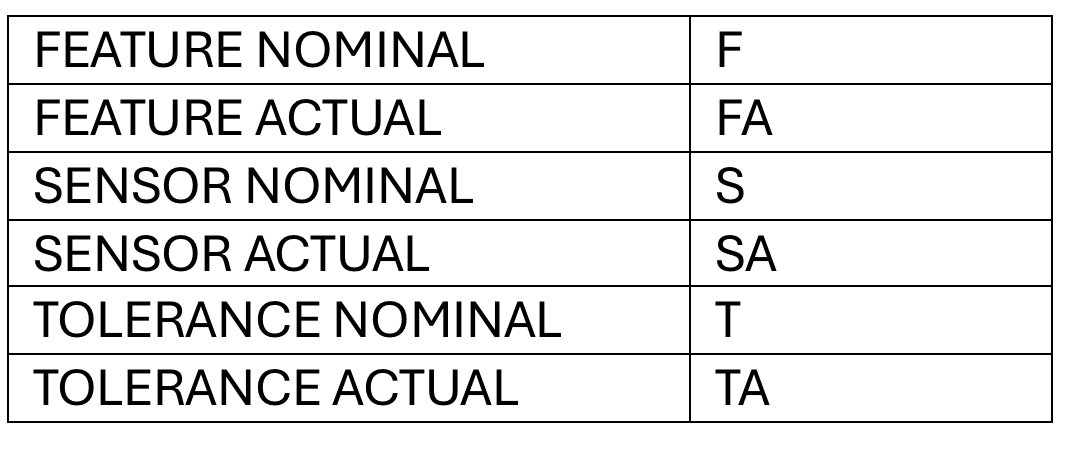

Define the feature nominal. After the feature is measured the results are shown as FA() inside the parathesis will be the feature name or label.