THE DIFFERENCE BETWEEN STATED ACCURACY AND ACCREDITED ACCURACY

How to Interpret the Accuracy of Measuring Instruments?

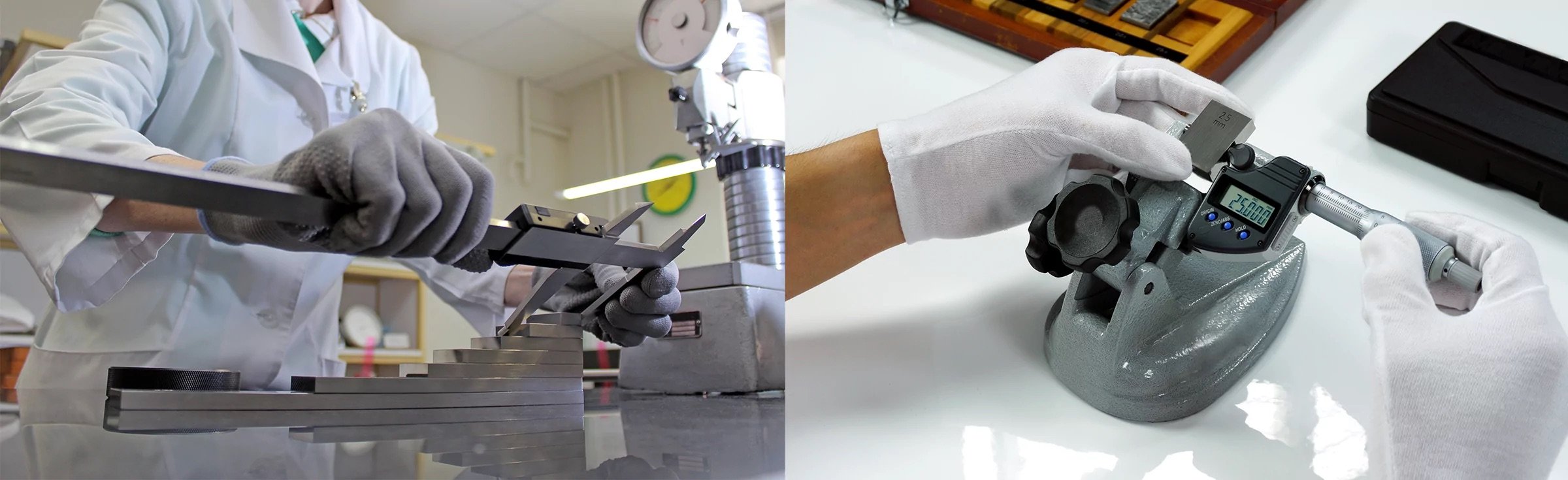

Stated accuracy refers to the accuracy that a manufacturer claims its measuring devices have, while accredited accuracy is an objective measurement of that product’s true accuracy. Simply put, stated accuracy is a claim, while accredited accuracy is a verified fact. It is important for users to understand this difference when making purchasing decisions, especially for measurement equipment used in applications that require high accuracy, such as quality control (QC) and quality assurance (QA).

Accuracy: More than a Specification

Accuracy is not only a number mentioned on a specification sheet. Not only is the accuracy specification an indicator of the manufacturer’s seriousness and commitment to quality, but it also reveals the level of technical expertise, knowledge, and proficiency it may possess to develop and produce high-quality and reliable measuring instruments.

If you are confused about all the data presented, here is an explanation of how to interpret the accuracy of a measuring instrument. Because behind this data lies quality standards, best practices, and countless tests and verifications inherent to the equipment manufacturer’s rigor, transparency, and focus.

Accredited Accuracy Refers to Quality Standards

Measurement equipment manufacturers are required to follow specific tests and evaluations directed by the certification standard they choose to comply with. The decision to use a standard or not, and whether it is a national or international standard, reflects the level of commitment and seriousness of the manufacturer towards ensuring the quality and repeatability of its products.

ISO 17025, A Mark of Excellence

ISO 17025 is an international standard that specifies the technical and management requirements of the calibration measurement laboratory, providing a recognized framework to ensure the accuracy, reliability, and interoperability of test and calibration results. In short, when a measurement equipment manufacturer has a calibration procedure following the ISO 17025 certification, it means that their calibration laboratory meets the high standards set by this certification in terms of technical competence, quality management, and the ability to perform accurate and reliable calibration results.

Manufacturers who have achieved ISO 17025 certification may display a certification mark or logo on the calibration certificate of their products. This certificate provides evidence of the calibration and includes details, such as the calibration date, the conditions under which the calibration was performed, the measurement uncertainty, and the traceability of the measurements.

VDI/VDE 2634 part 3, Assurance to Users of Optical 3D Scanners

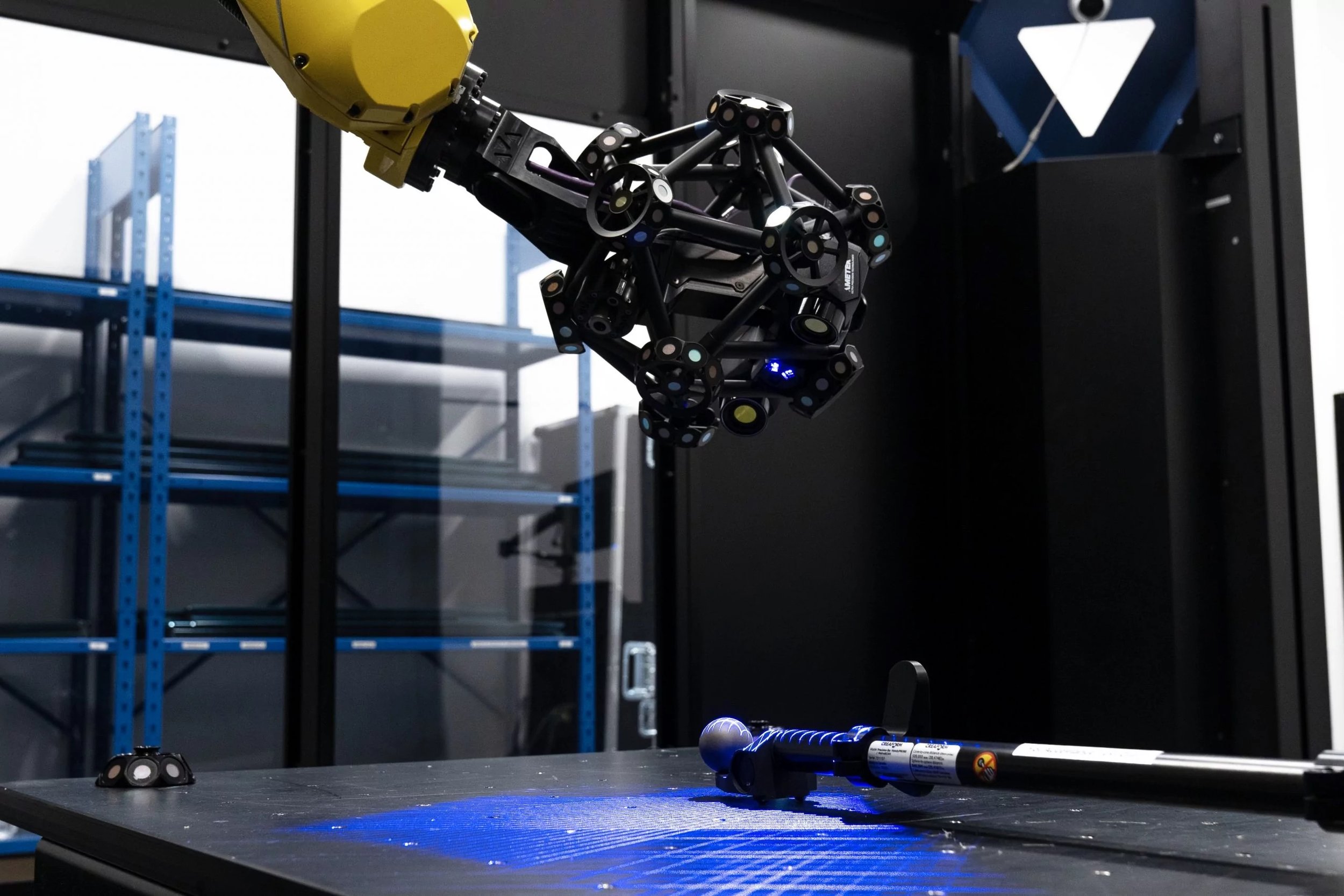

VDI/VDE 2634 part 3 is a German standard that provides guidelines for the acceptance testing and re-verification of optical 3D measuring systems. When a 3D scanner is certified according to VDI/VDE 2634 part 3, it means that the device has been tested and meets the requirements outlined in this standard for accuracy, repeatability, and reliability in 3D measurements.

In other words, the German standard states that the 3D measuring system has been tested to measure the dimensions and shapes of parts accurately, produce the same measurement results under the same conditions, and perform reliably over time and under various conditions.

ISO 10360, More Tests for More Assurance

ISO 10360 is a series of standards that specify the performance requirements for different types of coordinate measuring systems and the procedures for their acceptance and re-verification. When an optical 3D measuring device is certified according to ISO 10360, it means that the device has been tested and meets the requirements outlined in this international standard. These requirements include probing form and size errors, uni and bidirectional length measurement errors (volumetric accuracy), flat form measurement errors (flatness), etc. Volumetric accuracy testing typically involves taking multiple measurements of calibrated artifacts of different lengths in various orientations within the working volume.

Performance Consistency Relies on Regular Tests and Periodic Verifications

Regular tests and periodic verifications are necessary to ensure the optimal functioning and performance consistency of optical 3D measuring systems. The responsibility to carry out these tests and verifications lies with both the manufacturer and the user of the 3D measurement equipment.

To do so, manufacturers must provide users with procedures for acceptance testing and re-verification of optical 3D measuring systems, regardless of their design, level of automation, or complexity. These tests should be quick and easy to perform using low-cost artifacts. Suitable artifacts for these tests include length standards and other objects that the user can measure with the system just as any usual part.

Know How to Interpret a Specification

Properly interpreting and understanding an accuracy specification on a datasheet is crucial for users who want to assess different vendors and compare their solutions, leading to better purchasing decisions and product satisfaction.

Beware of Specifications with Prefix “up to”

Another element that makes the difference between stated and accredited accuracy is reflected when comparing the specifications of different manufacturers. Certified manufacturers use the term maximum permissive error (MPE). This is very different from a specification “up to” a certain value.

MPE is a more specific and rigorous way of expressing the allowable error in a measurement, as it sets a strict upper limit on the error permissible for the equipment under specified conditions. When a specification uses MPE, it indicates that the manufacturer has defined a clear boundary for the maximum error that can occur, which provides users with a higher level of confidence in the accuracy and reliability of the equipment.

However, specifications that mention “up to” a certain value can be less precise, as they indicate that the error could be anywhere from zero to the specified value. Still, they do not guarantee that the error will not exceed that value. This type of specification leaves some uncertainty about the worst-case performance of the equipment.

MPE specifications are considered more trustworthy and reliable because they provide a more precise and stringent definition of the equipment’s performance limits. MPE ensures that all measurement results are within the specifications.

Multitude of Standards, Tests and Details: Guarantee of Quality and Transparency

When a manufacturer certifies its measurement equipment according to various quality standards, such as ISO 17025, VDI/VDE 2634, and ISO 10360, and implements more rigorous tests each year in its calibration procedure, it shows its dedication to producing high-quality products. Additionally, if the calibration certificate includes an impressive quantity and level of detail, it indicates that the manufacturer is transparent and committed to providing more reliable, accurate, and consistent equipmentto its customers.

Accredited Accuracy, A Synonym for High-end Manufacturer

To achieve ISO certification, a manufacturer must demonstrate a commitment to maintaining high-quality standards in their processes, products, and services. This certification reflects a dedication to quality, continuous improvement, customer satisfaction, and operational excellence, all of which are key characteristics of high-end manufacturers.

When the ISO certification is combined with a strong brand reputation built on a history of delivering quality and reliable products, users can be assured that the accuracy of their 3D measuring devices is a verified fact they can fully trust, testifying of the manufacturer’s seriousness and rigor.