You have choices, make the right choice

Embracing the Future: Key Trends Shaping Metrology

As industries continue to push boundaries in manufacturing and technology, metrology—the science of measurement—has become a cornerstone of innovation. The need for precision and efficiency has never been greater, and metrology is evolving to meet these demands.

Advancing Camper Van Manufacturing with SHINING 3D FreeScan Combo Series

This case introduces how VANTECH enhanced its camper van manufacturing process by adopting SHINING 3D’s FreeScan Combo series. By upgrading 3D scanning technology, VANTECH significantly reduced costs, improved scan accuracy, and boosted productivity—achieving faster processing for vehicle design and production.

Automating Portable Manual CMMs

The evolution of 3D measurement systems has transformed manufacturing quality control, addressing diverse requirements for parts, tools, and assemblies.

How can I measure a large part with a portable 3D measuring device?

Within the large machine manufacturing industry, operators are faced with a number of challenges when it comes to measuring a large part.

Measurement at the heart of the shop floor, Hi-Spec Precision comment on their latest CMM purchases

Recently launched by Aberlink, the Extol is a shop floor hardened CMM that not only performs rapid, accurate and repeatable inspections in the most challenging environmental conditions, but boasts an incredibly compact footprint - allowing the CMM to be positioned where it is most needed, on the shop floor.

FARO Joins RFK TeK Alliance

FARO Technologies, Inc., the global leader in 3D measurement, imaging and realization solutions has joined eight-time NASCAR champions RFK Racing as part of the RFK TeK Alliance to create the FARO technology center. The Center will feature FARO’s best in class 3D metrology hardware and software to support all of RFK’s competitive efforts.

FARO Releases New Edition to its Portable CMM Series – FARO Quantum X New arm series increases accuracy and boosts user confidence

FARO Technologies, Inc. has announced the release of the Quantum X FaroArm Series of portable coordinate measurement machines. The Quantum X Series offers an up to 15% increase in accuracy compared to previous Quantum Max FaroArms, with probing and scanning designed to improve manufacturing efficiency in a configurable and scalable solution.

3D SCANNING TO IMPROVE QUALITY CONTROL IN ADDITIVE MANUFACTURING PROCESSES FOR LARGE PARTS

There are tremendous benefits for companies in various sectors to leverage additive manufacturing processes and technologies, such as 3D printing, to create parts that are lightweight, yet strong. From accelerated prototyping to improved agility in customizing designs to significant reduction of surplus part inventory, additive manufacturing brings unprecedented efficiency and cost savings to manufacturing operations.

Should a CMM be replaced with a robot?

Deciding whether to replace a Coordinate Measuring Machine (CMM) with a robotic measurement system can be challenging. To make an informed choice, it’s essential to understand the unique strengths and limitations of each technology. Let’s explore this in more detail, with examples to help you visualize the differences.

Accurate Inspection Right Next To Your Machine Tool

The Fulcrum is a revolutionary manual CMM, by employing a three rotary axis design, Aberlink have created a space-efficient tabletop design enabling it to be used where it is needed, on the shop floor near your machine tools.

SMART STEPS TO INTEGRATING 3D SCANNING IN YOUR QUALITY CONTROL

Integrating 3D scanning technology into quality control processes can be challenging. It requires balancing the need for cost-effective, scalable solutions with long-term effectiveness.

INNOVATIVE 3D SCANNER SERVING THE LARGEST INDUSTRIAL PARTS A CREAFORM’S CLIENT SUCCESS STORY FEATURING SIEMENS ENERGY

With over 90,000 employees worldwide, Siemens Energy is a global company operating in various sectors of the energy industry, including grid technologies, decarbonization of industries, wind energy, and conventional power generation.

UNVEILING THE HIDDEN HURDLES OF AUTOMOTIVE PART MANUFACTURERS

Manufacturing sheet metal is far from a simple task. It requires rigorous inspection, primarily due to the high quality and stringent safety standards required in the automotive industry. No doubt, a combination of advanced technology and skilled labor must be involved to ensure that the sheet metal components are cut and shaped to precise dimensions. This includes checking for correct length, width, surface profile, and overall shape. Quality inspection is vital because automotive sheet metal must withstand stress and fatigue over the vehicle’s lifetime.

CREAFORM ON BOARD TO HELP AMERICAN MAGIC WIN THE 37TH AMERICA’S CUP

At the end of August 2024, the New York Yacht Club’s American Magic set sail from Barcelona in its bid to win the Louis Vuitton 37th America’s Cup. According to organizers,

How Metrology Technology is Helping Car Companies Manufacture the Latest EVs

Almost everyone is aware of the electric vehicle (EV) revolution in the automotive industry. The switch from diesel and petrol engines to electric power is constantly in the news, and despite some obstacles to widespread adoption, the clock is ticking to a total switch by 2035. Here Gareth Tomkinson, Business Development Manager in Renishaw’s CMM & Gauging Products Division, explores the role of metrology in solving these challenges.

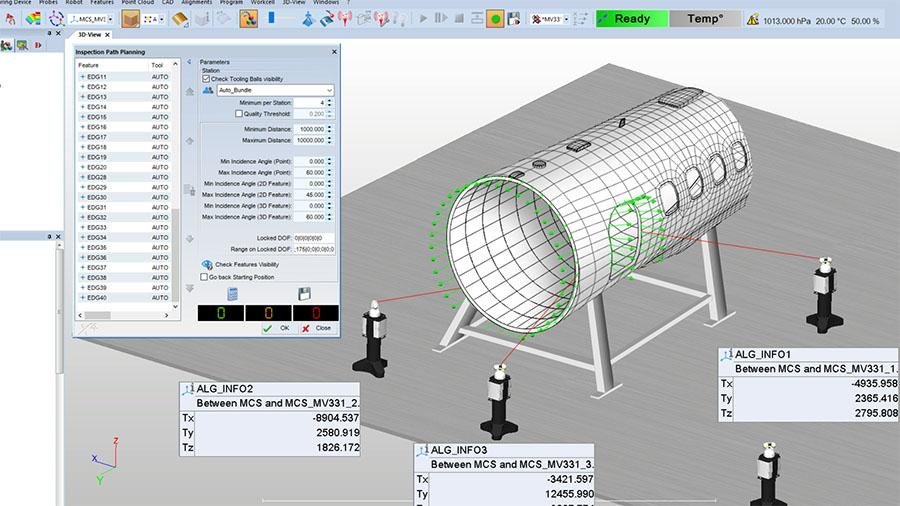

Verisurf Software Announces Inspection Planner Suite to Enhance Manufacturing Process Control

Inspection Planner lets users quickly and easily create and execute inspection plans for arms, trackers, scanners, and manual CMMs. It also supports executing proven inspection plans on CNC CMMs supporting all 3-axis and 5-axis probing systems. The Inspection Planner workflow supports CAD, Model-Based Definition (MBD)/Product Manufacturing Information (PMI), plan creation and execution, and GD&T reporting and analysis.

LK Metrology Portable Measuring Arms

All 34 portable measuring arms offered in 6-axis touch-probing and 7-axis multi-sensor variants by LK Metrology, Castle Donington, are now supplied as standard with a 4.5 inch diameter mounting ring to allow the unit to sit on a larger base, rather than that provided by the previous 3.5 inch ring. The result of having this extra stability is that the new Version 3 FREEDOM Arms are capable of measuring to higher precision. A mounting ring adapter can be supplied if an existing user already owns an LK tripod or stand with a 3.5 inch mount. Mechanical, magnetic and vacuum fixing alternatives are available.