You have choices, make the right choice

How to meet the challenges of large-scale metrology?

Everything that needs to be measured to certain specifications falls within the scope of metrology, from the smallest products such as nuts, bolts and screws, spectacle frames and pens, to household appliances, aircraft, trains, cars, trucks and boats.

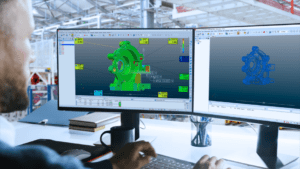

How a complete solution can help meet the challenges of 3D metrology

With the right solution, 3D metrology can not only improve measurement precision and accuracy, but also eliminate rework, reduce iterations and facilitate troubleshooting by providing rich data on defective products without having to physically disassemble the parts

How to share software between 3D measuring devices

In the world of manufacturing, large companies have different plants, partnerships, subcontractors and facilities through which the relevant and necessary metrological data is shared between them. The main aim is to avoid repetitive measurements and redundant efforts that could lead to potential conflicts between measurement data, which can be time-consuming and counter-productive.

How to choose the right 3D measuring system

Metrology has undergone a significant evolution with the advent of 3D measurement and scanning technologies. By 2025, the global 3D scanning market alone is expected to reach $53,345 million, according to Allied Market Research. Indeed, the global manufacturing industry is currently undergoing radical transformations thanks to the harnessing of the capabilities of 3D measurement devices.

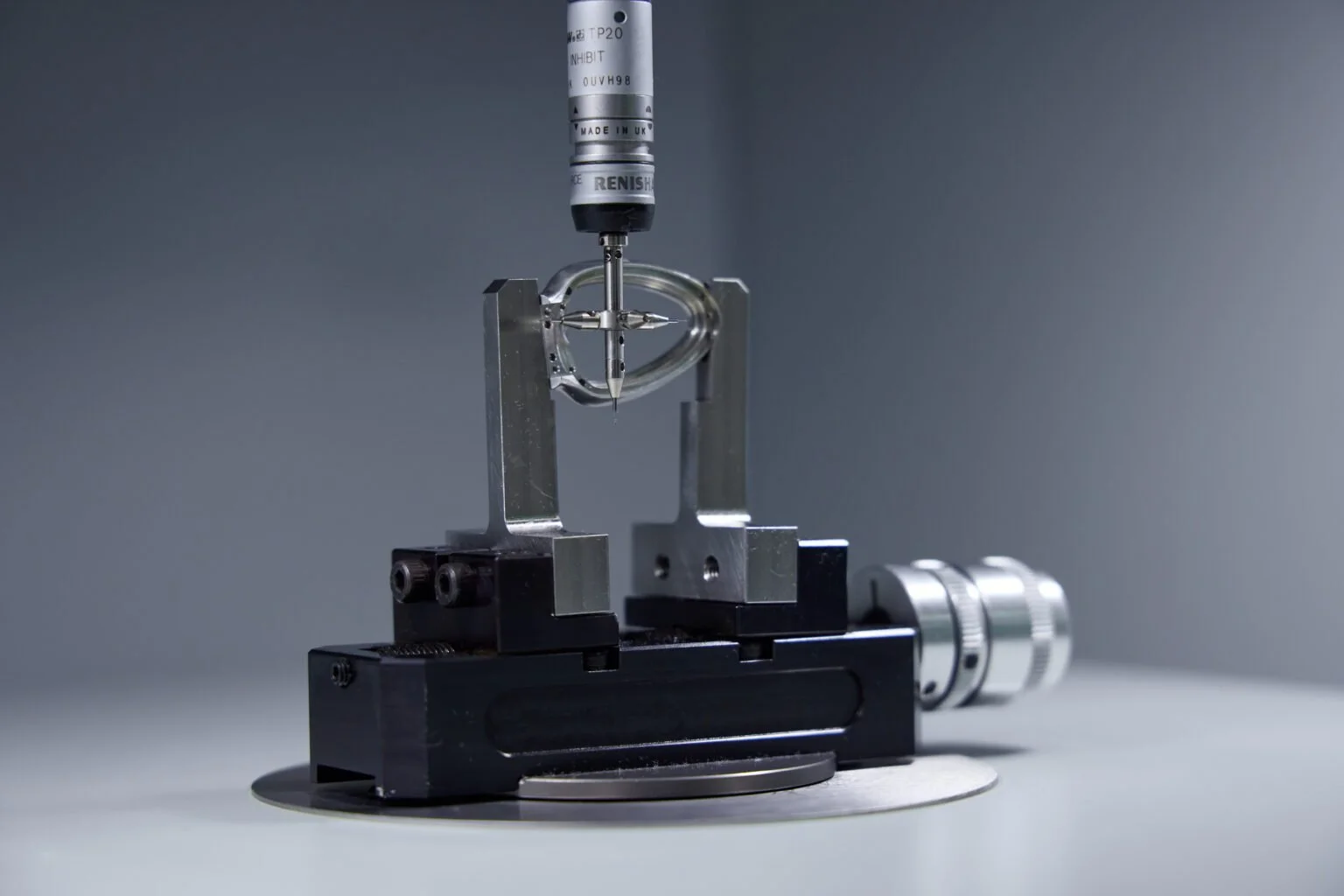

When fine watchmaking relies on people and technology to achieve excellence

Based in Switzerland, the watchmaking division of Italian watchmaker Bvlgari combines the brand’s bold aesthetic with Swiss watchmaking expertise. Renowned for its ultra-thin models, including the iconic Octo Finissimo, the manufacture masters the entire process, from in-house movement to final assembly.

New partnership: Metrologic Group and Horus Metrology sign an agreement in Mexico

Horus Metrology’s solid expertise in on-site measurement and automation in Mexico, combined with Metrologic Group’s universal software solutions, enables it to offer customized, turnkey solutions to companies wishing to automate their inspection processes.

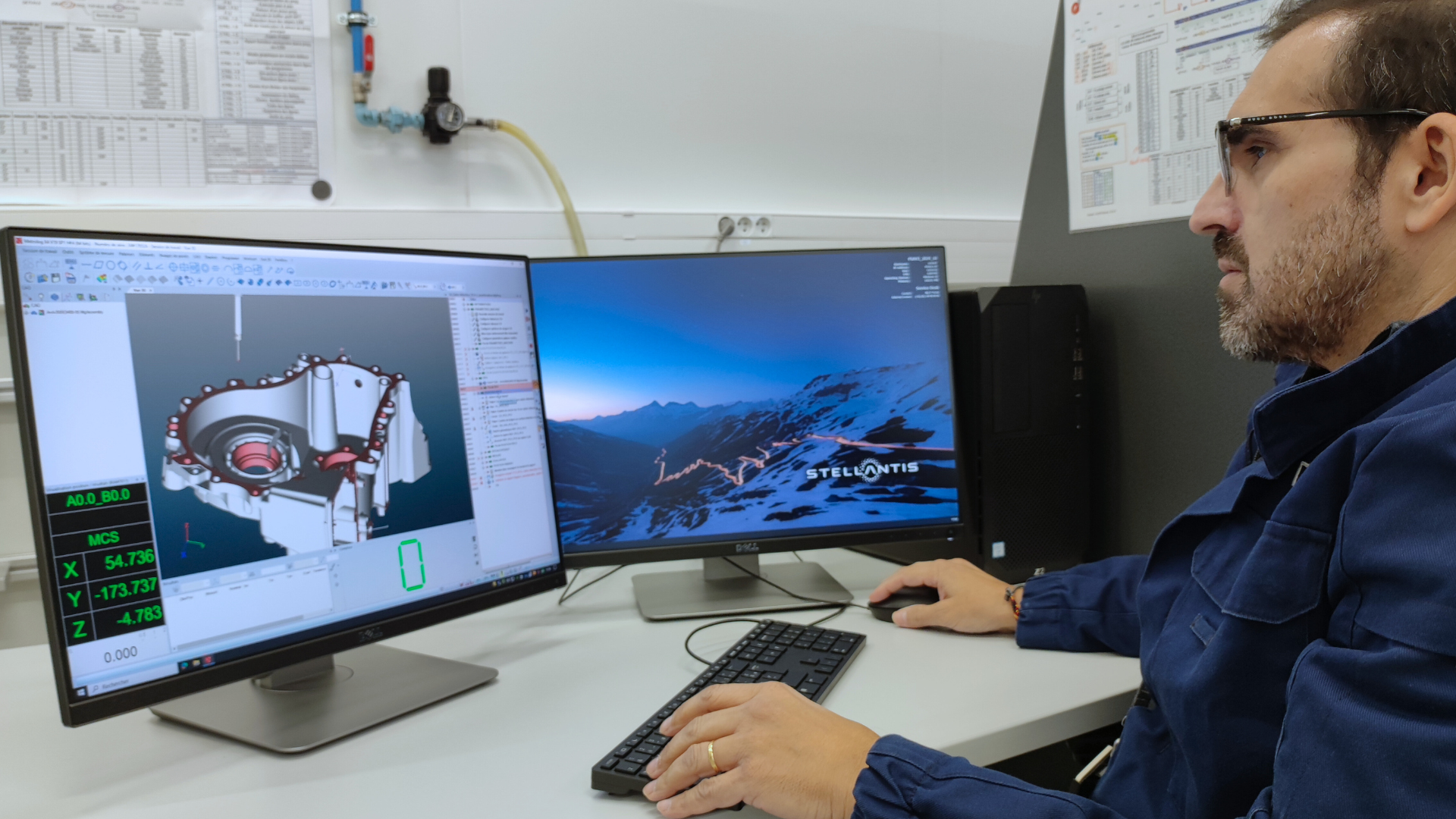

Stellantis Restore CMM Peak Performance and Maximize Life With Software Retrofit

Stellantis is a global automotive manufacturer resulting from the merger between the PSA Group and FCA in 2021, which today markets fourteen automotive brands worldwide.

Reducing costs and improving productivity with metrology

Margins are under constant threat and businesses need to find ways to reduce costs, improve efficiency and productivity, and drive down waste. Metrology can help alleviate some of these pressures on the business when used efficiently.

New partnership with Metromecánica

Metromecánica’s strong expertise in robotic inspection and automation, coupled with Metrologic Group’s universal software solutions, enables it to offer customized, turnkey solutions to companies wishing to automate their inspection process.

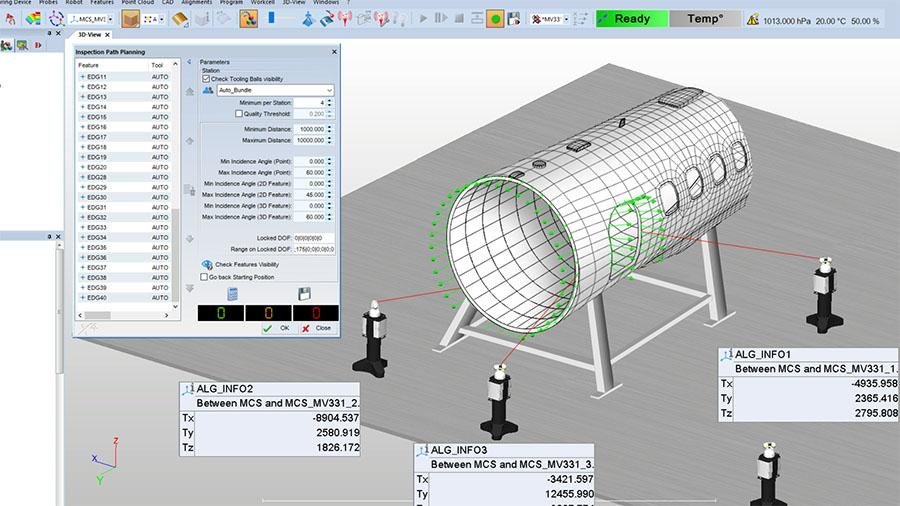

How can I measure a large part with a portable 3D measuring device?

Within the large machine manufacturing industry, operators are faced with a number of challenges when it comes to measuring a large part.

What are the effectiveness and gains of 3D point cloud inspection?

Point cloud technology refers to the use of a set of data points in a 3D coordinate system, which is commonly defined by X, Y and Z axes. From a metrological standpoint, the actual points in a point cloud represent those X, Y and Z geometric coordinates for each single point.

Metrologic Group and QFP announce strategic partnership for customized 3D metrology solutions

Metrologic Group, a software development company specializing in 3D metrology and quality control, has entered into a partnership with QFP, a provider of customized measurement systems for 3D metrology.

Why invest in 5-axis CMMs technology?

There are growing demands within the global manufacturing industry to increase productivity and efficiency levels at faster paces. As a result of this, metrologists are starting to find out that using Coordinating Measuring Machines (CMMs) that only operate using 3-axis machining technologies is not enough anymore.

How can GD&T be used to reduce risks in 3D measurement processes?

Geometric Dimensioning and Tolerancing (GD&T) is a system that is used to define and communicate engineering tolerances particularly in the automotive, aerospace, electronics and commercial design industries for the past few decades.

How to keep up with the pace of change in automotive quality control?

In today’s fast-paced automotive industry, flexibility is no longer optional, it’s essential. With rapid changes in market demands, evolving trade regulations, and technological advancements, manufacturers need to respond swiftly to remain competitive.

How robotic inspection can resolve 3D quality control challenges

When it comes to improving inspection processes in manufacturing, deploying robots to help is becoming more and more of a reality today.

In the manufacturing industry, typical applications of industrial robots include product assembly, welding, painting, product inspection, testing, packaging and labelling, etc. According to recent industrial reports, the global robotic inspection sector alone is predicted to grow by $4.68 billion during 2023-2029.

What are the effectiveness and gains of 3D point cloud inspection?

Point cloud technology refers to the use of a set of data points in a 3D coordinate system, which is commonly defined by X, Y and Z axes. From a metrological standpoint, the actual points in a point cloud represent those X, Y and Z geometric coordinates for each single point.

Should a CMM be replaced with a robot?

Deciding whether to replace a Coordinate Measuring Machine (CMM) with a robotic measurement system can be challenging. To make an informed choice, it’s essential to understand the unique strengths and limitations of each technology. Let’s explore this in more detail, with examples to help you visualize the differences.