You have choices, make the right choice

Nikon’s Large-Envelope X-Ray CT System Installed in Hyundai Motor North America’s New Safety, Investigation Laboratory

Nikon Metrology, Inc, and Hyundai Motor North America announced that Hyundai has purchased and installed Nikon’s X-ray computed tomography (CT) system. This represents a significant investment in the success of Hyundai’s newly opened $51.4 million Safety Test and Investigation Laboratory (STIL) in Superior Township, MI.

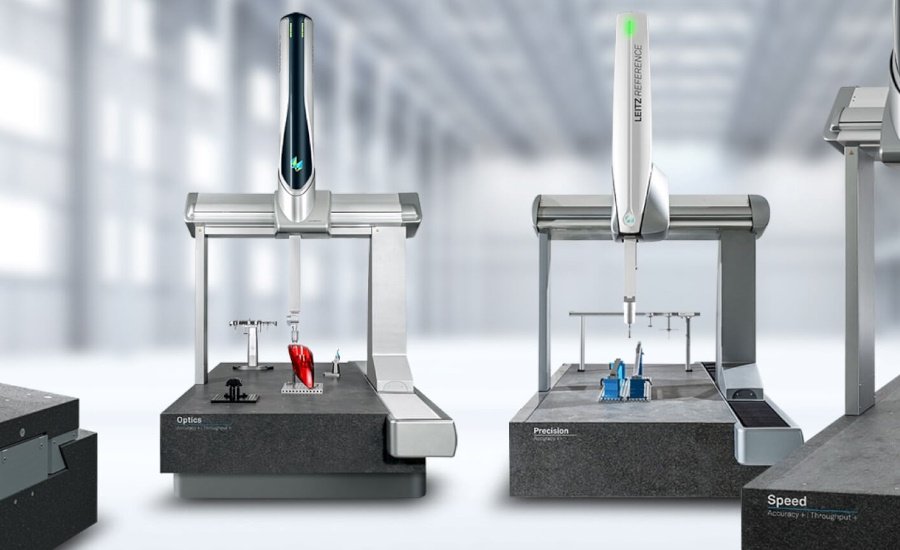

MSI Viking Announces Strategic Partnership with Hexagon Manufacturing Intelligence

MSI Viking announced a major new partnership in the Americas with Hexagon Manufacturing Intelligence, a division of Hexagon. This collaboration is set to enhance MSI Viking’s offerings in coordinate metrology, further solidifying its commitment to delivering excellence in the field.

Rapid inspection of large, tight-tolerance components

CMS Cepcor has significantly upgraded its quality control by acquiring an Altera M Coordinate Measuring Machine (CMM) from LK Metrology. This state-of-the-art CMM offers precise and repeatable inspections down to two microns.

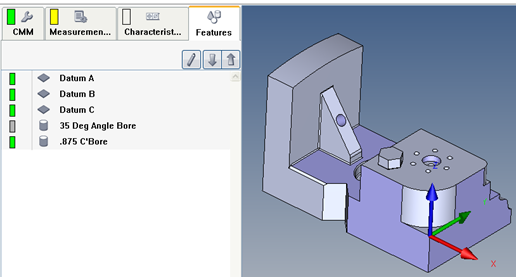

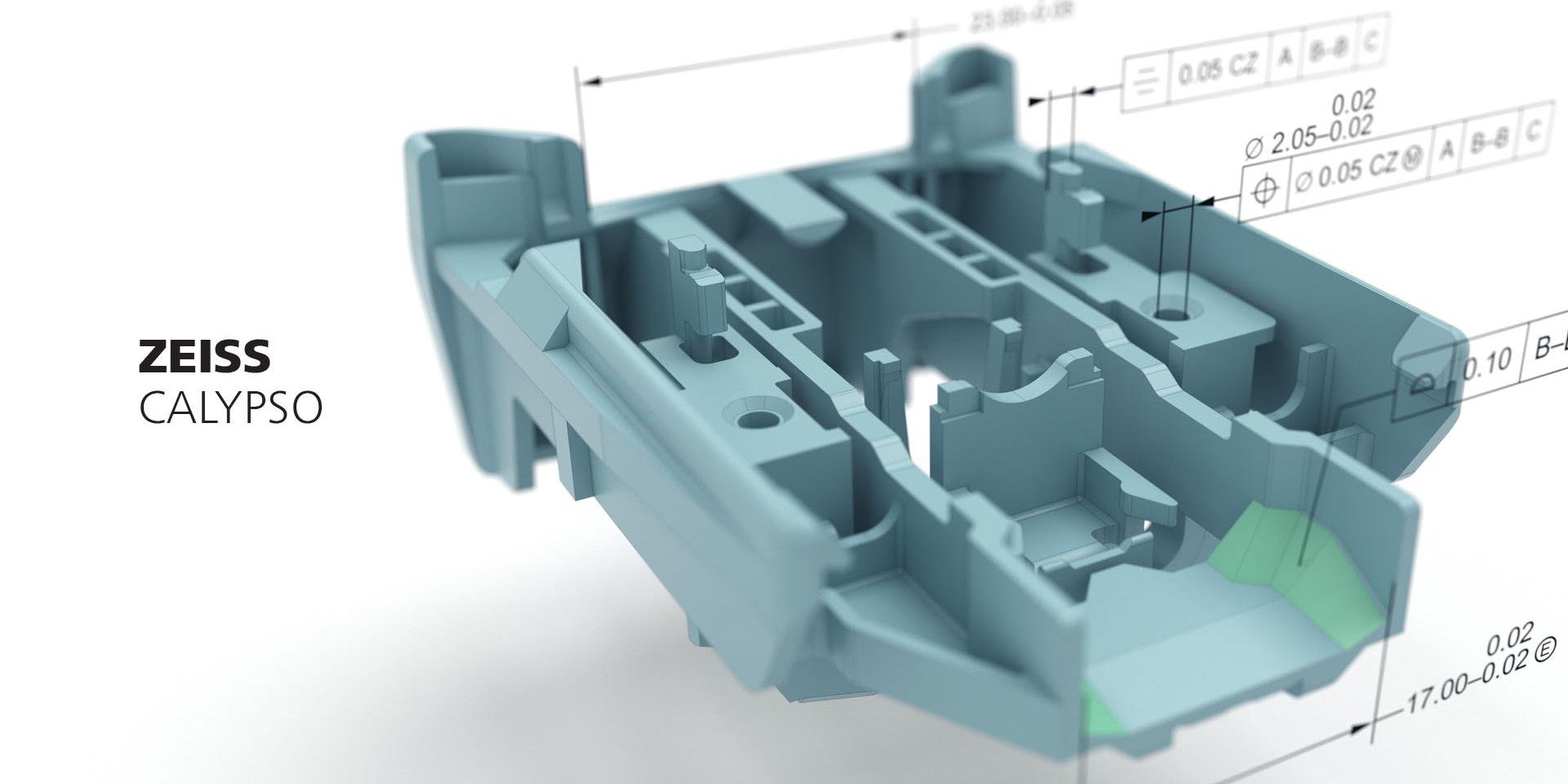

Calypso - Condition Based on Confirm Statement

What to expect. Yes, (it does exist) the CMM will measure the 35 Deg Bore. No, (does not exist) it will skip the 35 Deg Bore and move to the .875 diameter.

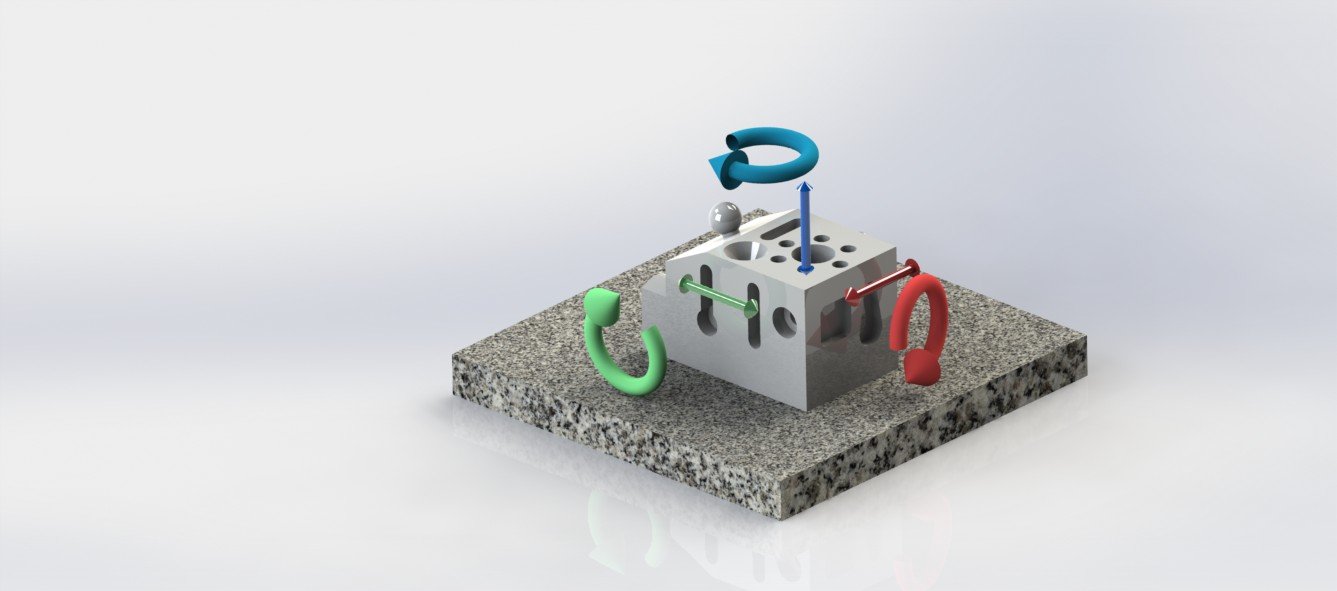

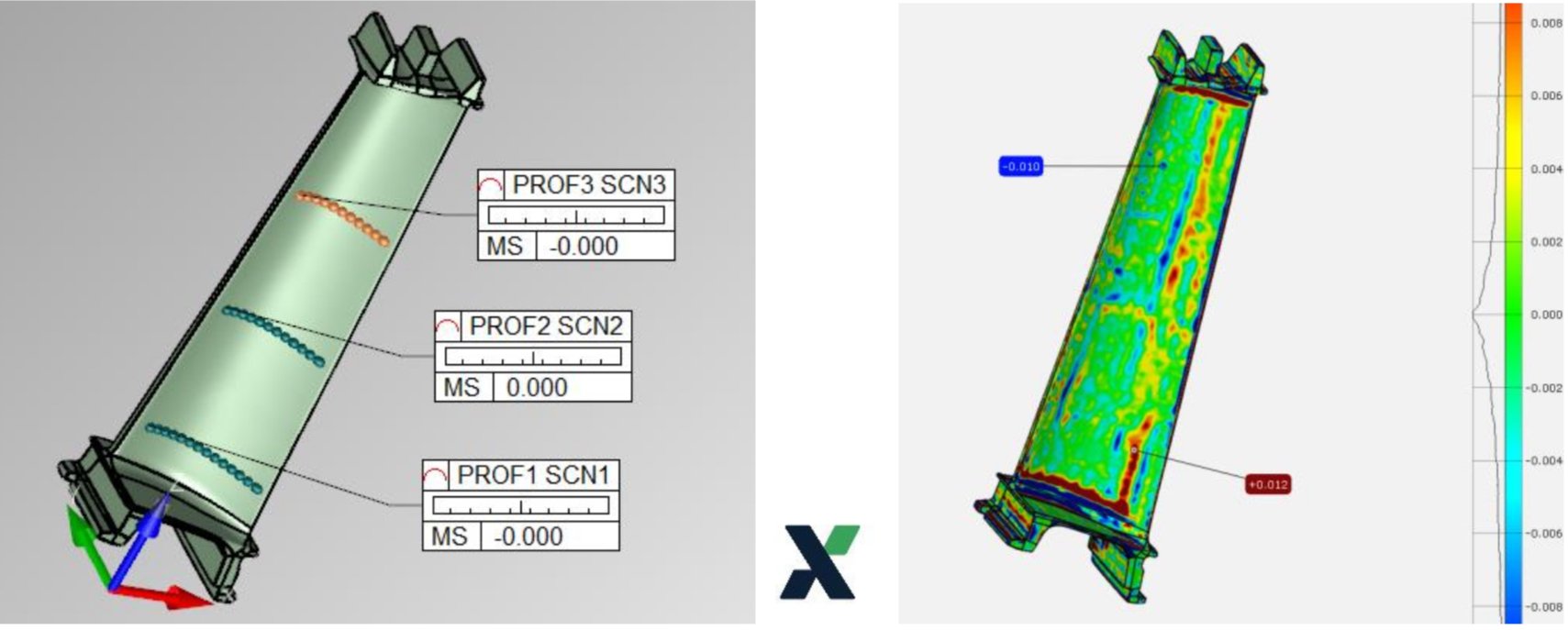

The efficiency and gains of 3D point cloud inspection

Point cloud technology refers to the use of a set of data points in a 3D coordinate system, which is commonly defined by X, Y and Z axes. From a metrological standpoint, the actual points in a point cloud represent those X, Y and Z geometric coordinates for each single point. All together, these point clouds can be used as they are (raw) or filtered to create shapes and surfaces that can be compared with a nominal CAD reference, for example.

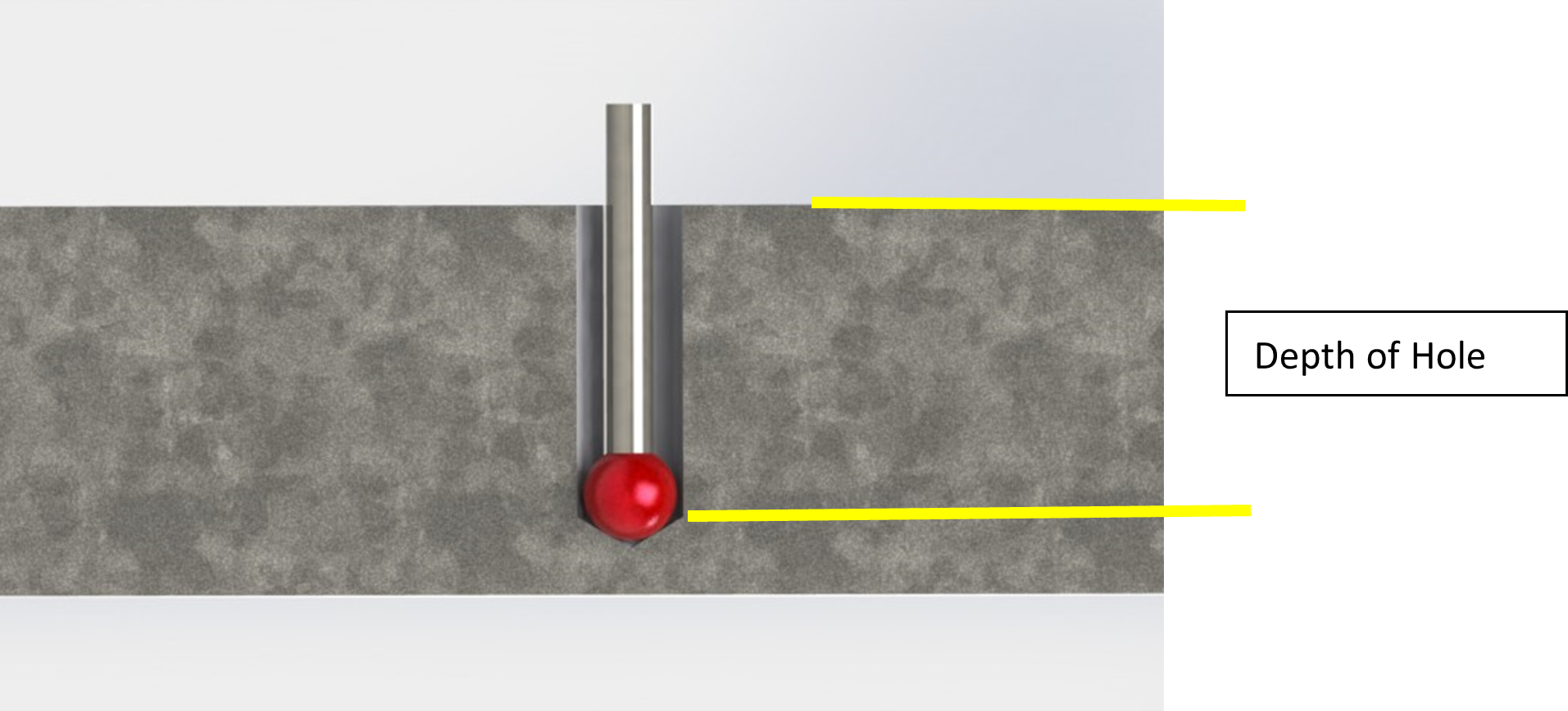

Calypso - Blind Hole Depth

This is an excerpt from the Calypso Handbook

To measure the depth of a blind hole we must calculate the depth by using this process.

Scantech Showcases Advanced 3D Scanning Solutions at Rapid + TCT 2024

Los Angeles, CA — Scantech, a leading provider of 3D solutions, showcased its latest advancements at the Rapid + TCT 2024, the largest and most influential additive manufacturing event in North America held from June 25 to 27 at the Los Angeles Convention Center.

Calypso - Point Recall with Loop

This will create a wall thickness 360° around the part top and bottom 8 points each.

Program

Do you have items in your cart?

Here is a discount code for purchases until the end of July

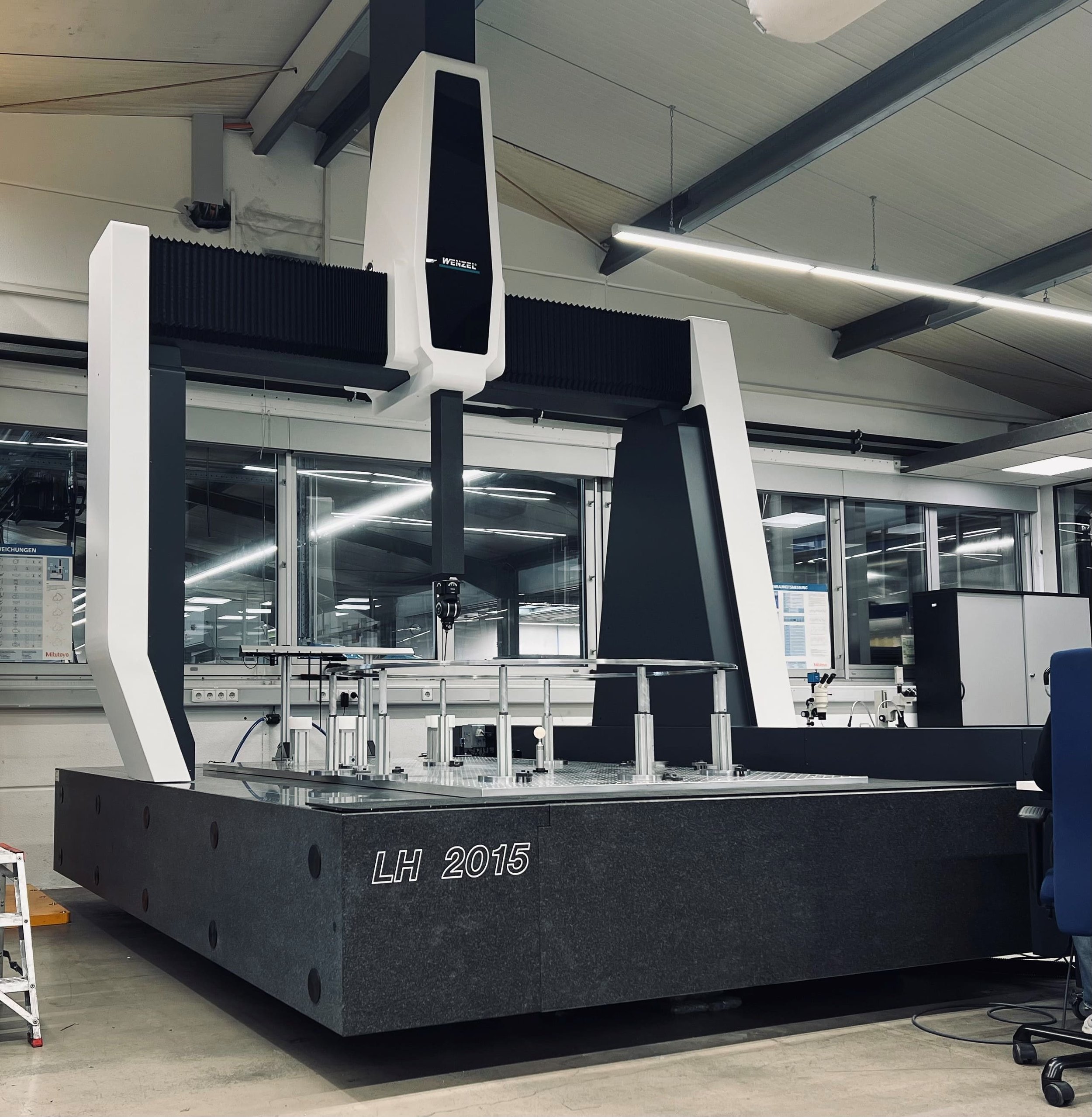

Maximum precision in machining production

The powerful LH 2015 CMM with WM | Quartis software and the REVO in use at BARTH.

Flatness - GD&T and Calypso Rev 3 Book

Flatness (form tolerance): the tolerance zone is limited by two parallel planes a distance t apart.

Implies: Straightness of the surface or Straightness of the derived median line

CMM Manager VB Scripting

Have you ever struggled with VB scripting in CMM Manager. This book will change that and elevate your cmm programming skills to a new level. This book will help you create practical dialog boxes like the one below.

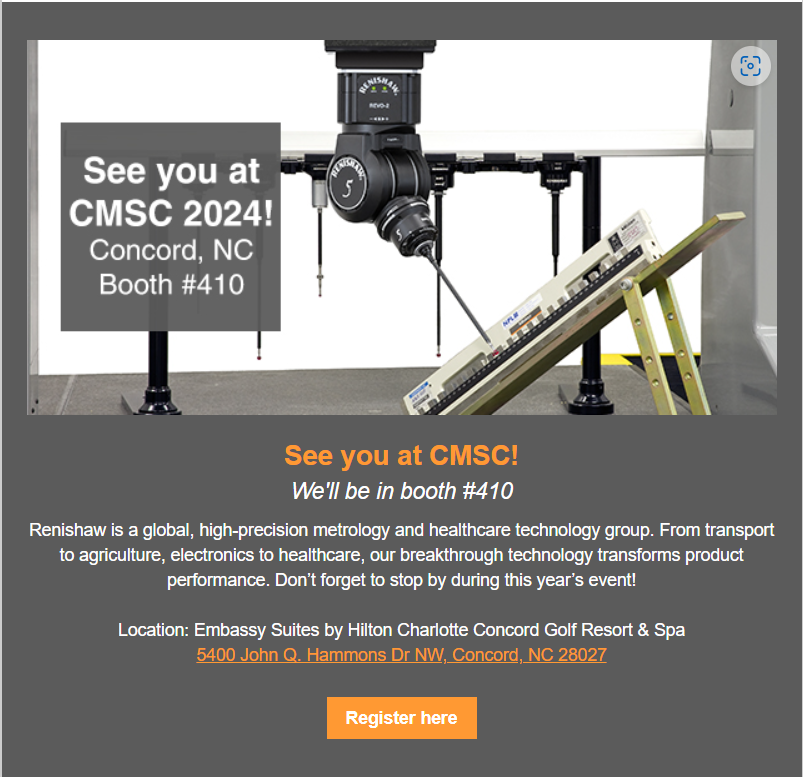

Renishaw - See you at CMSC!

The REVO system uses synchronized motion and 5-axis measurement technology to minimize the dynamic effects of CMM motion at ultra-high measurement speeds. This is achieved by letting the REVO-2 head do the fast-demanding motion while the CMM moves in a linear slow fashion. The use of a flexible tip-sensing probe further adds to the system's accuracy and performance. The removable probe system, used in conjunction with a low-cost changer, provides added system flexibility.

Higher Flexibility with Less Effort

To maintain their position as a market leader, many companies are committed to quality control – for example, by using coordinate measuring machines. However, only an ideal software makes a comprehensive and individual evaluation possible. ZEISS CALYPSO is the general measuring software enabling both tactile and optical measurements with ZEISS coordinate measuring machines as well as the verification and analysis of the resulting 3D data. The new software version has been released.

ZEISS Introduces Compact CMM for Precise Measurement of Large Volume Parts

ZEISS has launched the ZEISS MMZ 1 table CMM, designed specifically for large workpieces and applications that require highly accurate contact measurements. This machine excels in evaluating size, form, and location measurements with exceptional precision. Equipped with the ZEISS VAST XT gold probe head mounted on a silicon carbide ram, the ZEISS MMZ 1 offers enhanced temperature stability.

CMM Quarterly - who we are

CMM Quarterly has been around for 17+ years bringing CMM programmers and operators the real inside information they need. We have all read the ‘fluff’ pieces that some e-magazines put out or they own the site that puts out articles but wouldn’t know how to run a CMM to save their life.

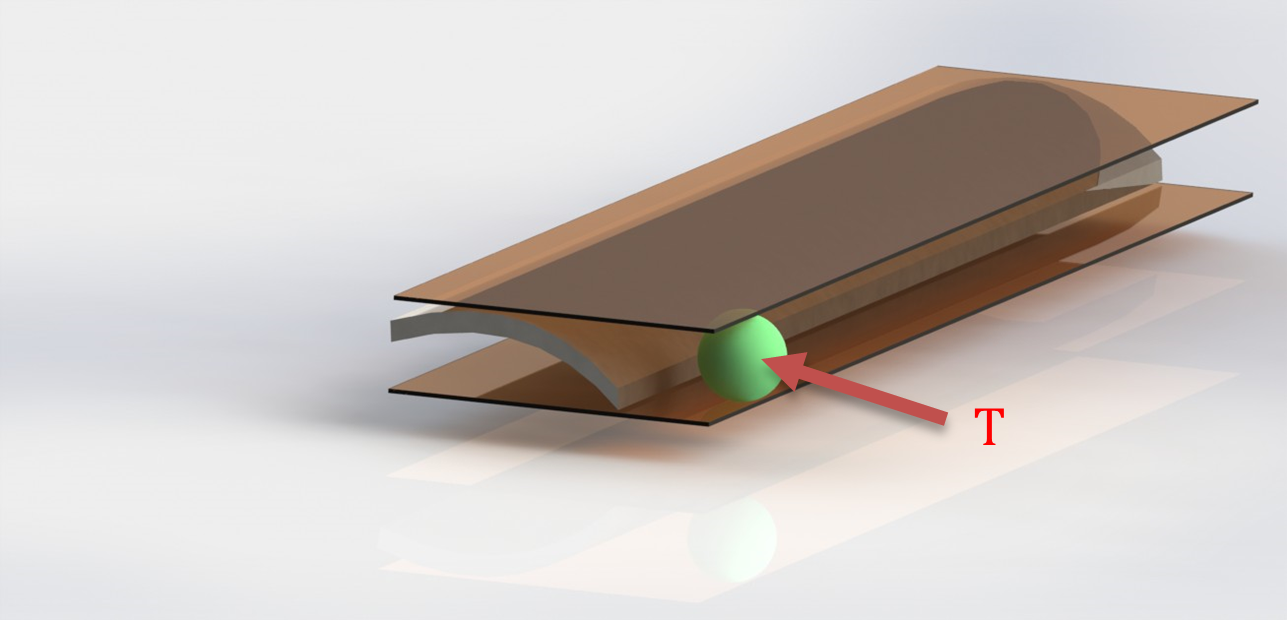

3D Scanning or Tactile Probing?

3D scanning technologies have been rapidly developing in the last 10 years and widely used in manufacturing industries for Metrology purposes. Although people get used to seeing various scanning systems and most time have good understanding on what this technology can bring to you, many common questions still remain such as “should I choose a 3D scanner or a CMM?”, “can I use the 3D scanner to totally replace my CMM?”, etc.

Motorsport: Driven by speed

Formula One is an innovative and high performance arena where speed, precision and accuracy is of the essence at all times. To maintain pole position, Oracle Red Bull Racing has been in a long-term technical partnership with Hexagon’s Manufacturing Intelligence division. Machinery heard more at the F1 team’s Milton Keynes factory